Defect data real time collecting device and method thereof, and production line real-time data capturing system

A real-time data acquisition and real-time acquisition technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of uncontrollable rhythm, difficulty in product classification and statistics, and small processing quantities, achieving automatic acquisition, easy Real-time collection, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

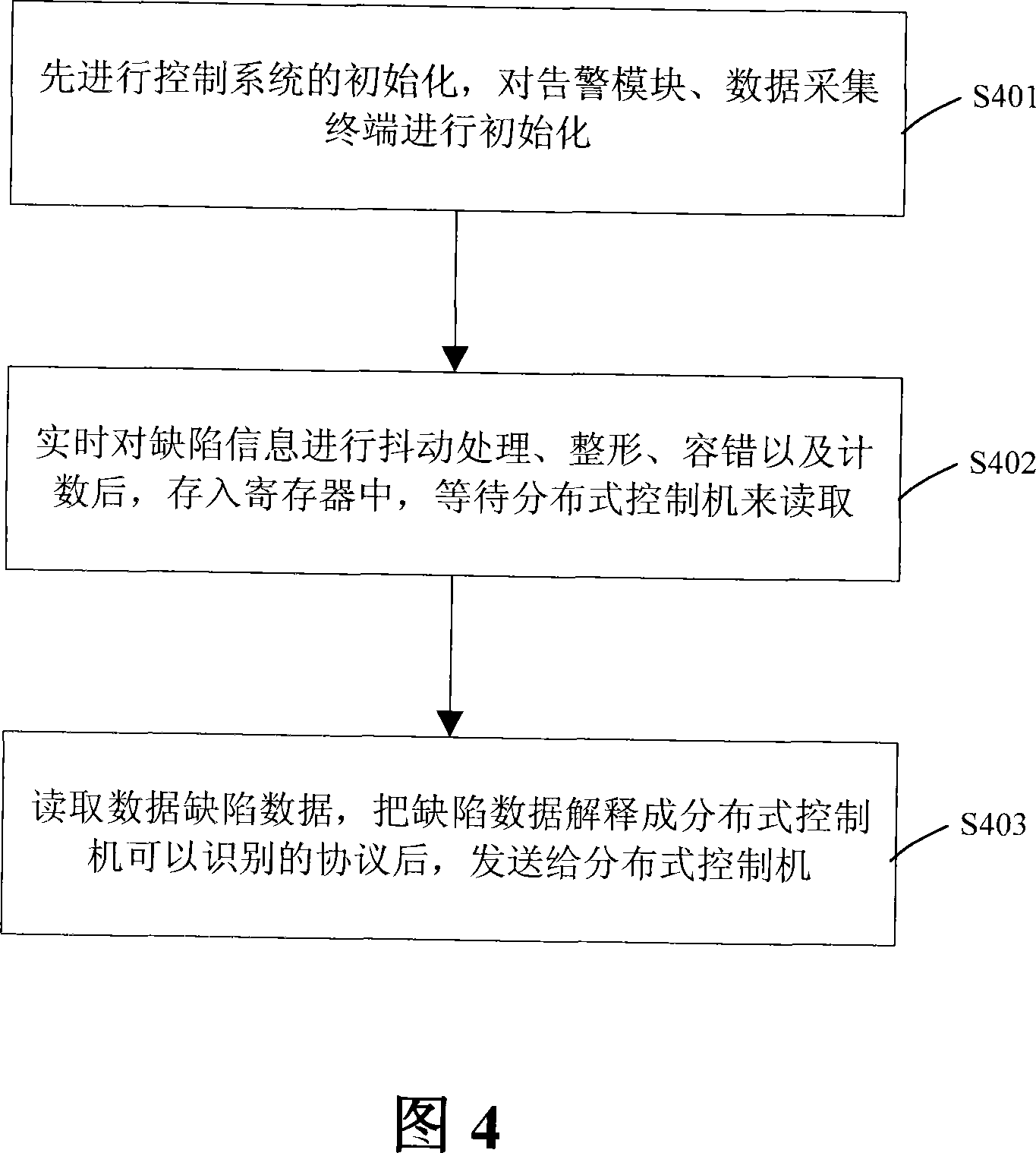

[0047] The technical solutions of the present invention will be further described in more detail in conjunction with the accompanying drawings and specific embodiments.

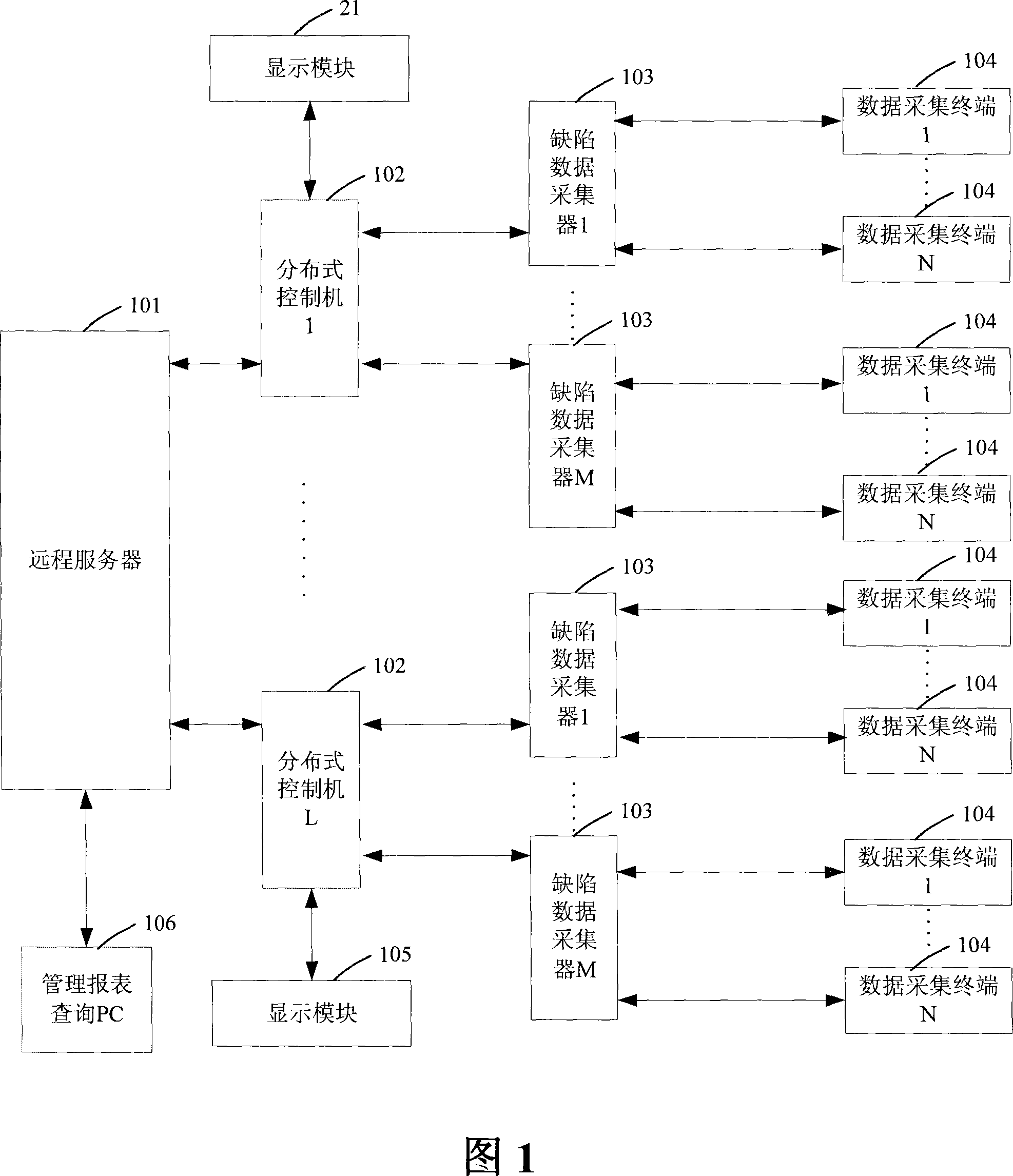

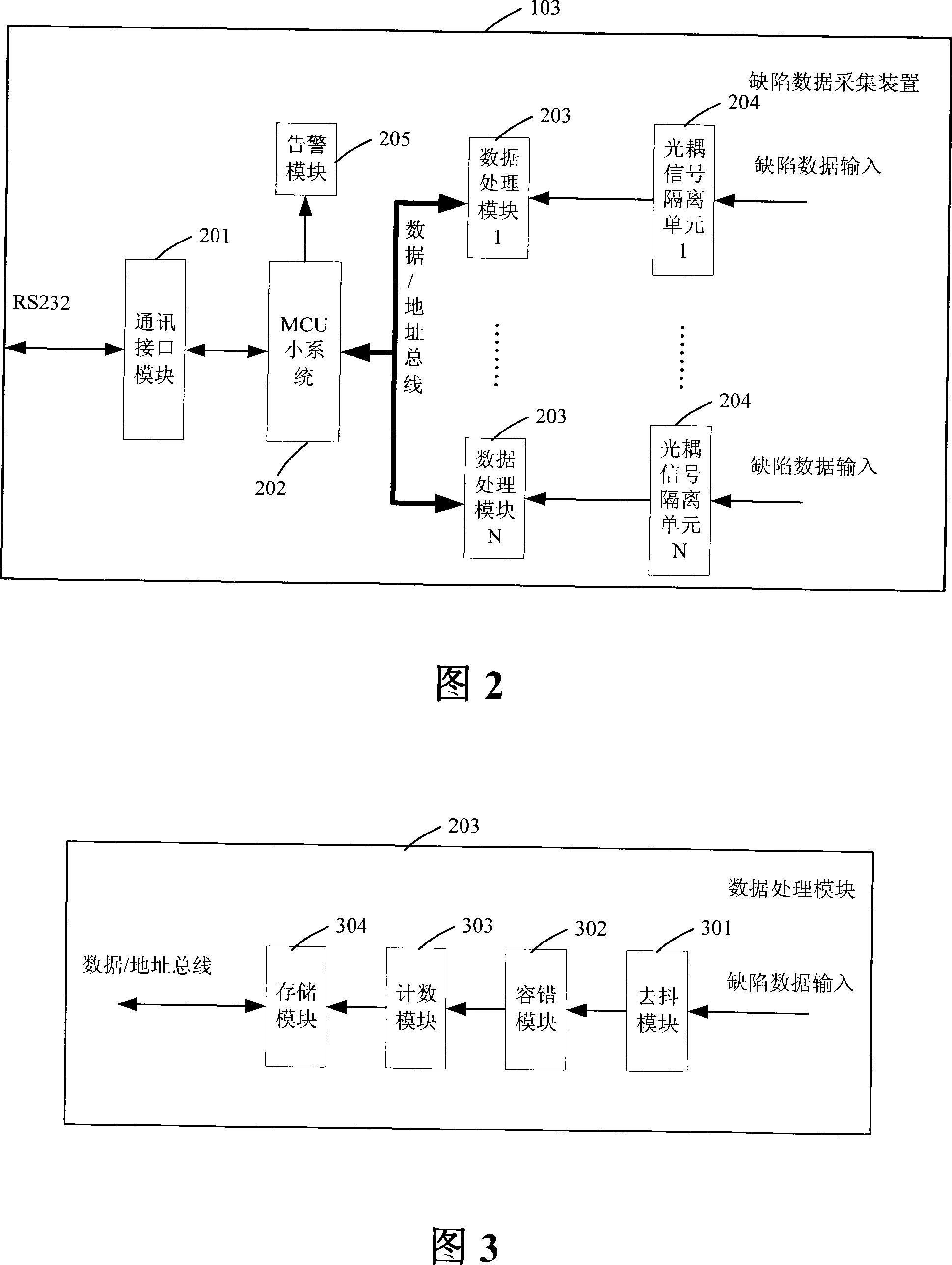

[0048] As shown in Figure 1, it is a structural block diagram of the real-time data acquisition system of the production line of the present invention. The structure includes: a remote server 101 , a distributed control machine 102 , a defect data collection device 103 , a data collection terminal 104 , a display module 105 and a report query terminal 106 .

[0049] The remote server 101 is the database of the entire system of the remote server system, and it is mainly responsible for the storage, analysis and report generation of various production status data of the production line.

[0050] Distributed control machine 102, including distributed control machine 1 ~ distributed control machine L, L is a natural number greater than or equal to 1, mainly used to realize the control of defect data collection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com