Vehicle complete fluid pressure turning drive bridge

A steering drive axle, full hydraulic technology, applied in the direction of hydraulic steering gear, steering mechanism, steering rod, etc., can solve the problems of reduced mechanical passability, limited output force, large volume of motor reducer, etc., to achieve service life and performance The effect of improving, using and sealing performance is good, and the structure setting is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

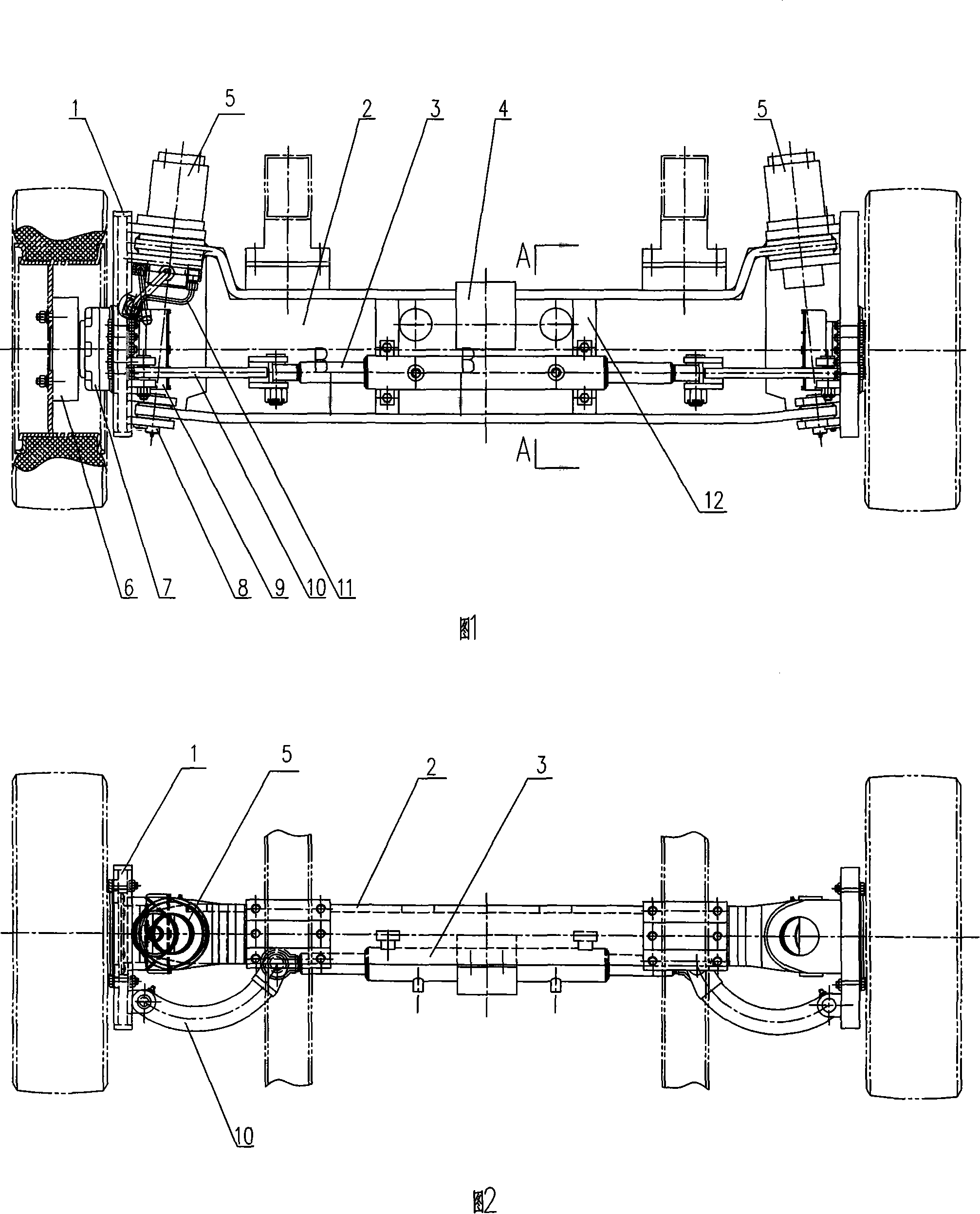

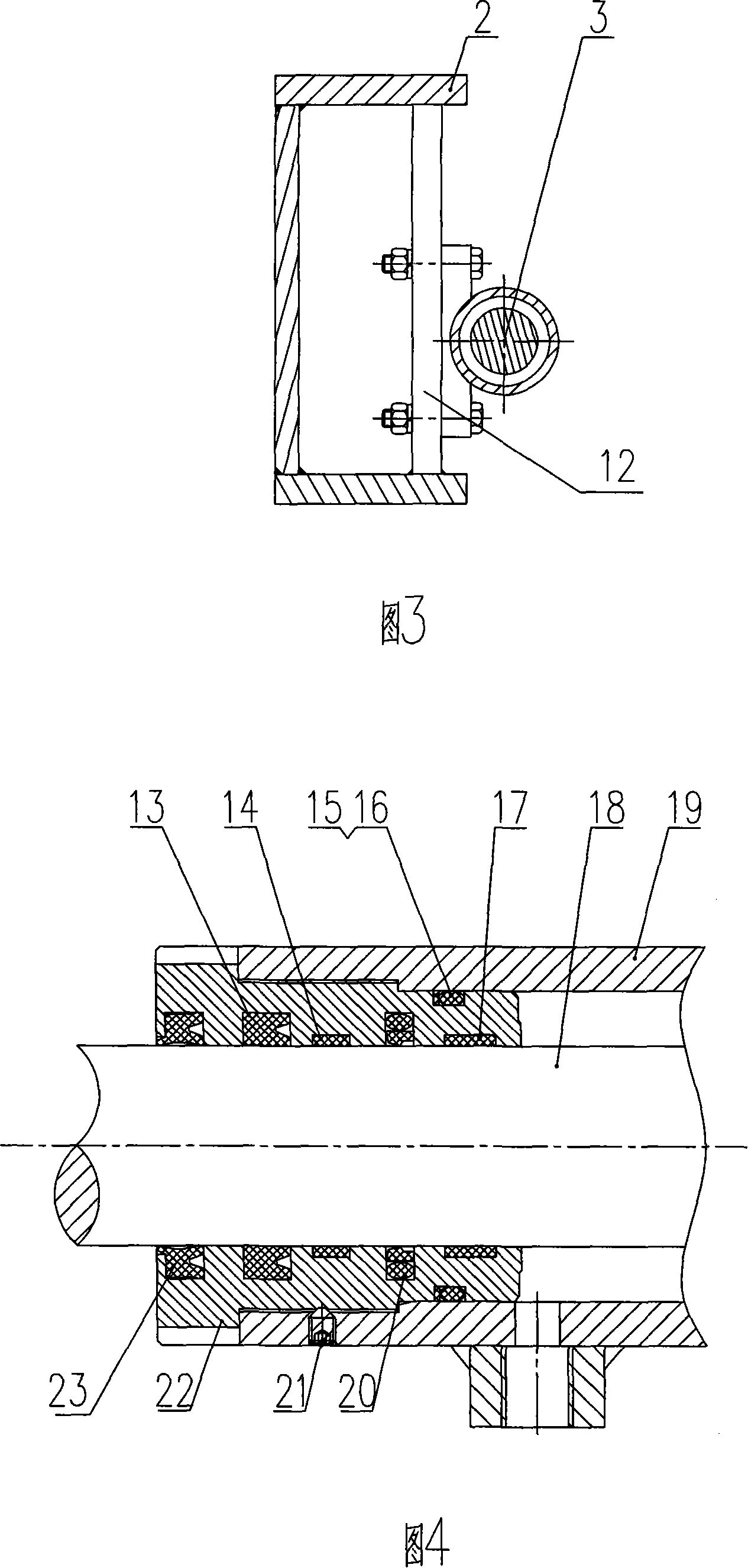

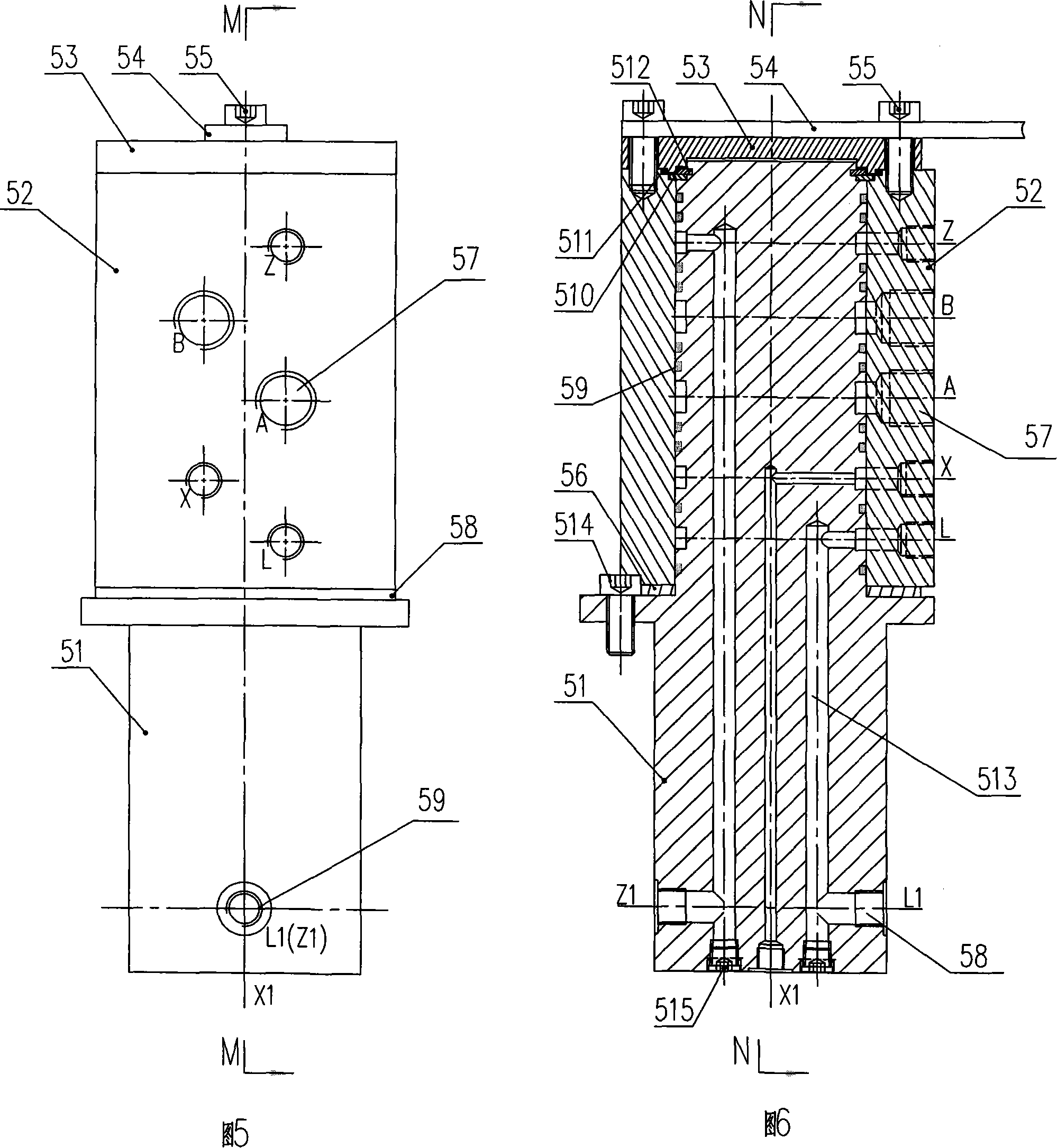

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The fully hydraulic steering drive axle has four functions of complete machine transmission, walking, steering and braking. Including the axle housing 2, the cross-section of the axle housing 2 is a channel steel type, the opening faces forward, and the two ends of the axle housing are symmetrically arranged with upper and lower hinge seats to be hinged with the steering knuckle, wherein the upper hinge The seat is hinged with the steering knuckle by installing a high-pressure rotary joint, and the lower hinge seat is hinged with the lower hinge seat of the steering knuckle through a pin 8; the steering knuckle is connected with the hydraulic motor 7, and the hydraulic motor 7 is a low-speed high-torque hydraulic motor , is configured with the double-flow swash plate axial variable piston pump to form a hydraulic closed circuit; the front and rear of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com