High-ductility steel for hot-bending bends and production method for hot rolled plates thereof

A hot simmering elbow, high toughness technology, applied in heat treatment equipment, heat treatment process control, temperature control and other directions, can solve the problems of low carbon content, many other alloying elements, and high production costs, reducing production costs and achieving reasonable composition design. , the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

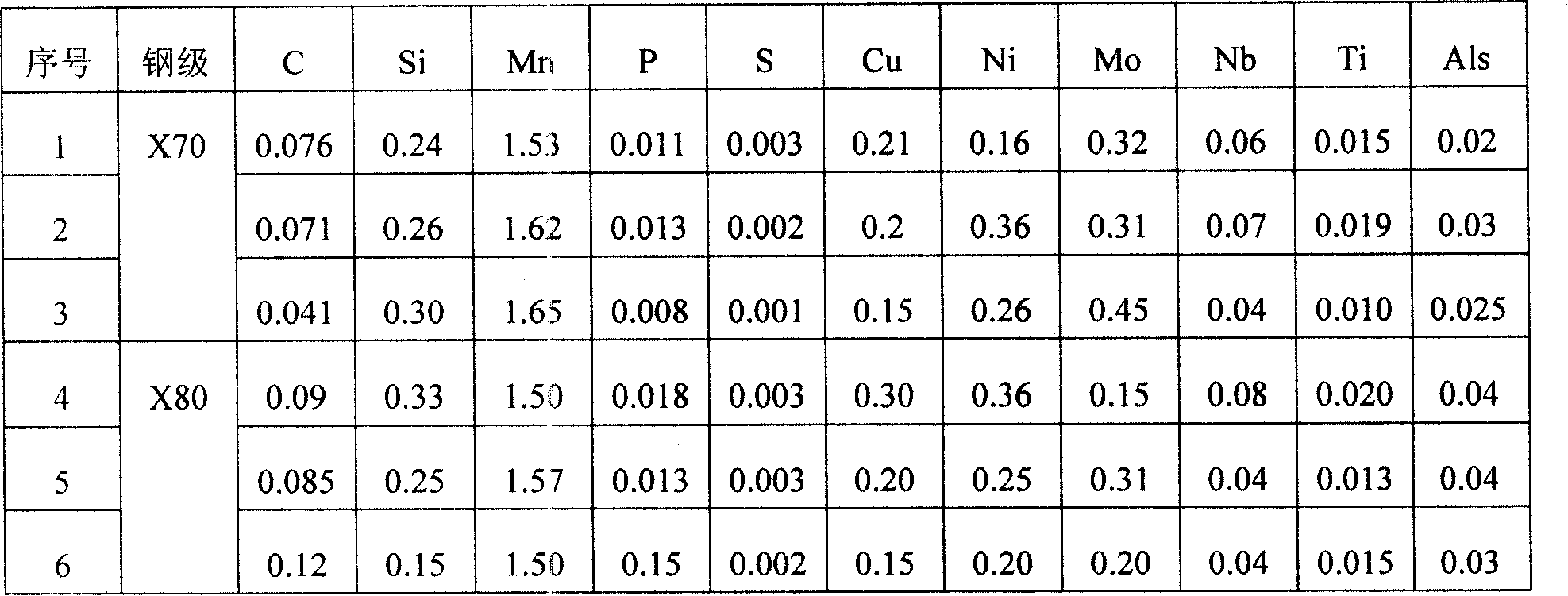

[0027] See Table 1 for the chemical composition of six examples of high-toughness steel for hot-simmering pipe bending according to the present invention, see Table 2 for the rolling process of the corresponding examples, see Table 3 for the performance test results, and see Table 4 for the performance after hot-simmering.

[0028] Table 1 The chemical composition of steel for high toughness hot-simmering pipe bending of the present invention

[0029]

[0030] Table 2 The rolling process of steel for high toughness hot-simmering pipe bending of the present invention

[0031] serial number

Rough rolling temperature range, ℃

Finishing temperature range, ℃

Cooling rate, ℃ / s

Final cooling temperature, ℃

1

1194

1100-1010

950-802

21

580

2

1220

1148-1030

950-805

18

594

3

1220

1150-1050

930-800

15

600

4

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com