Wheel brake

A wheel brake and brake technology, applied in the direction of brake type, brake components, axial brake, etc., can solve the problems of adjustment device failure, can not completely avoid the influence of automobile electric energy and signal system, etc., to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

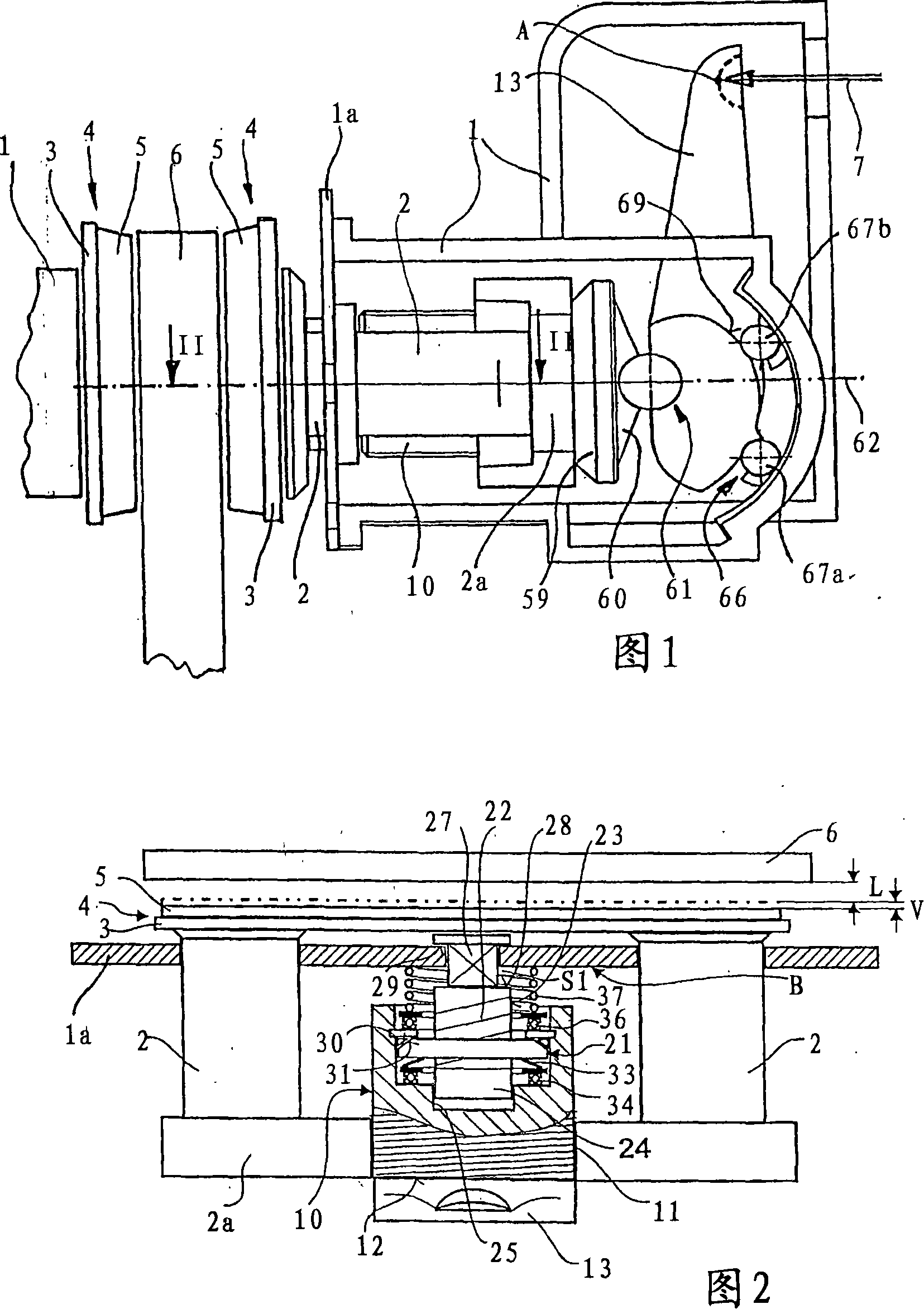

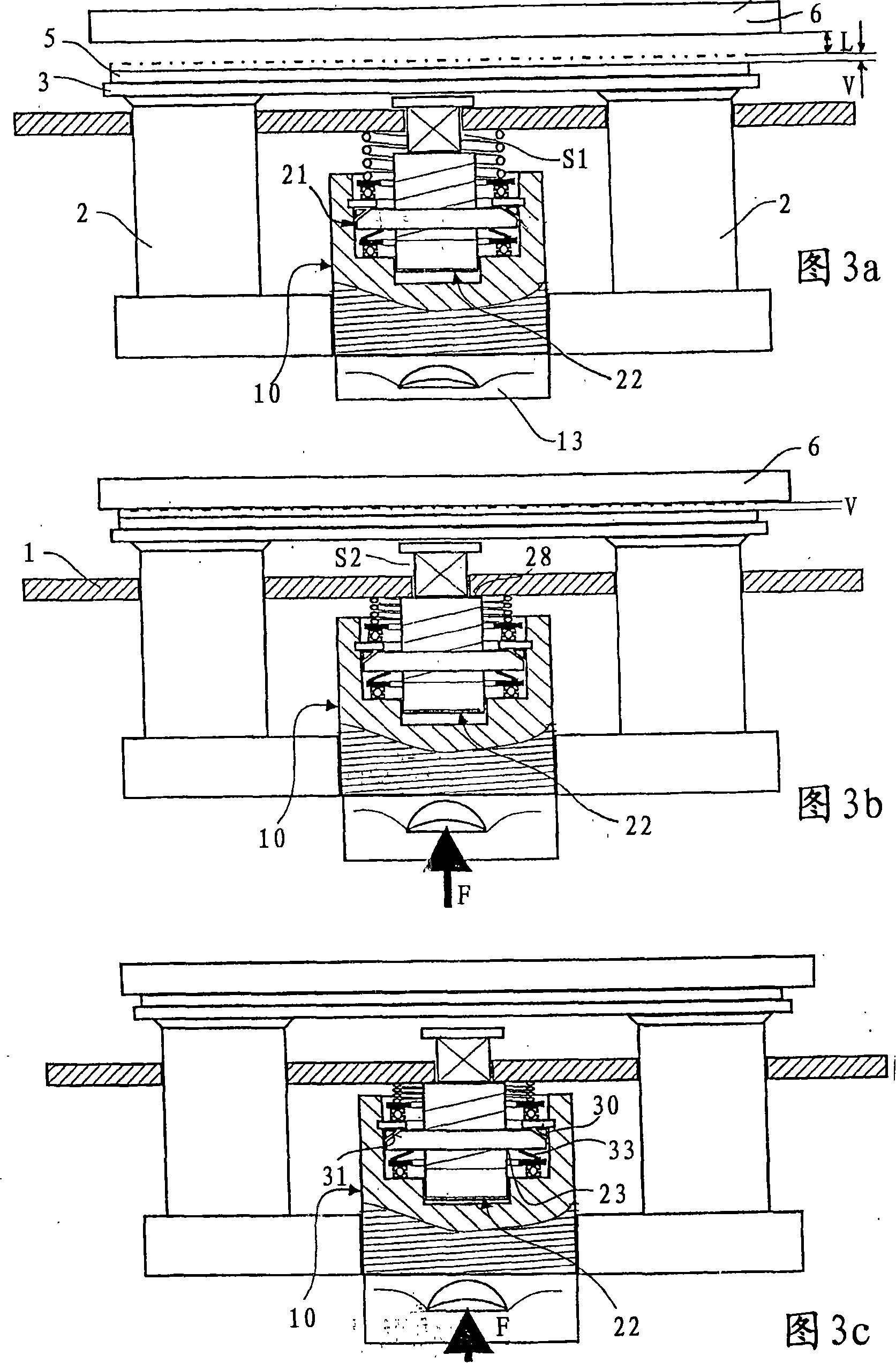

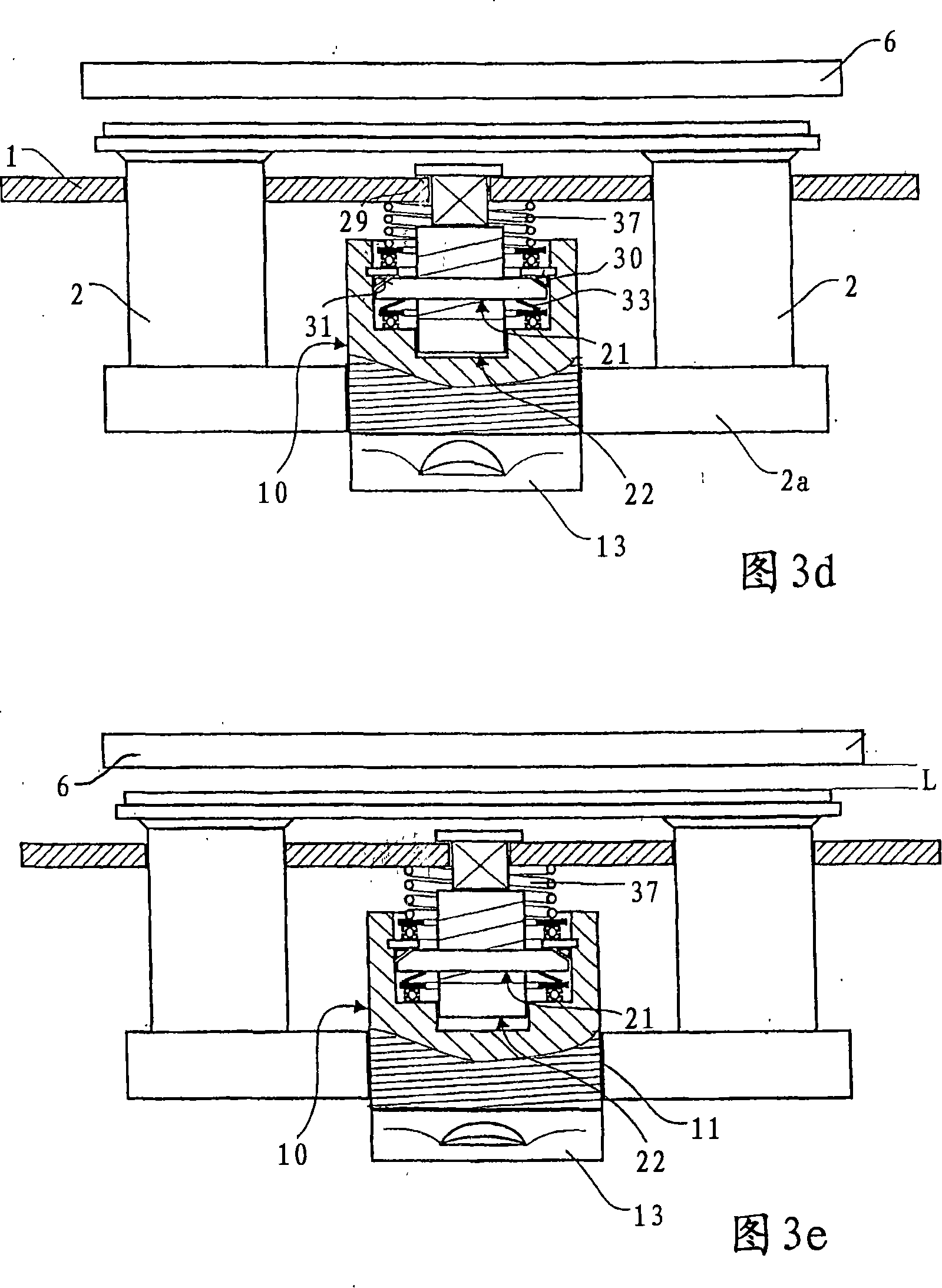

[0043] FIG. 1 shows a simplified illustration of part of a brake housing 1 of a motor vehicle disc brake, in particular of the floating caliper design. The two pressure plungers 2 are connected to each other within the brake housing 1 via a yoke 2 a extending transversely to the pressure plungers. Thus, as can be seen in particular from FIG. 2 , the two pressure plungers 2 form a double plunger which is supported outside the brake housing 1 on the rear side of the cover plate 3 of the brake lining 4 . 1 and 2 also show a brake lining 5 in addition to the brake lining 4 and also a brake disk 6 of the disk brake.

[0044]Disk brakes which operate with an air gap L (FIGS. 2, 3a) on both sides of the brake disk 6 during operation can be equipped with a purely mechanically operating adjustment device which will be described in more detail below. In order to transmit the pressing force generated by the brake cylinder and in particular the compressed-air actuated brake cylinder, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com