Screw teeth scrubbing plate set with cooling function

A technology of tooth rubbing plate and tooth plate, applied in the field of screw tooth rubbing plate group structure, can solve the problems of heat accumulation and poor heat dissipation, and achieve the effect of reducing heat energy accumulation, good quality level and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

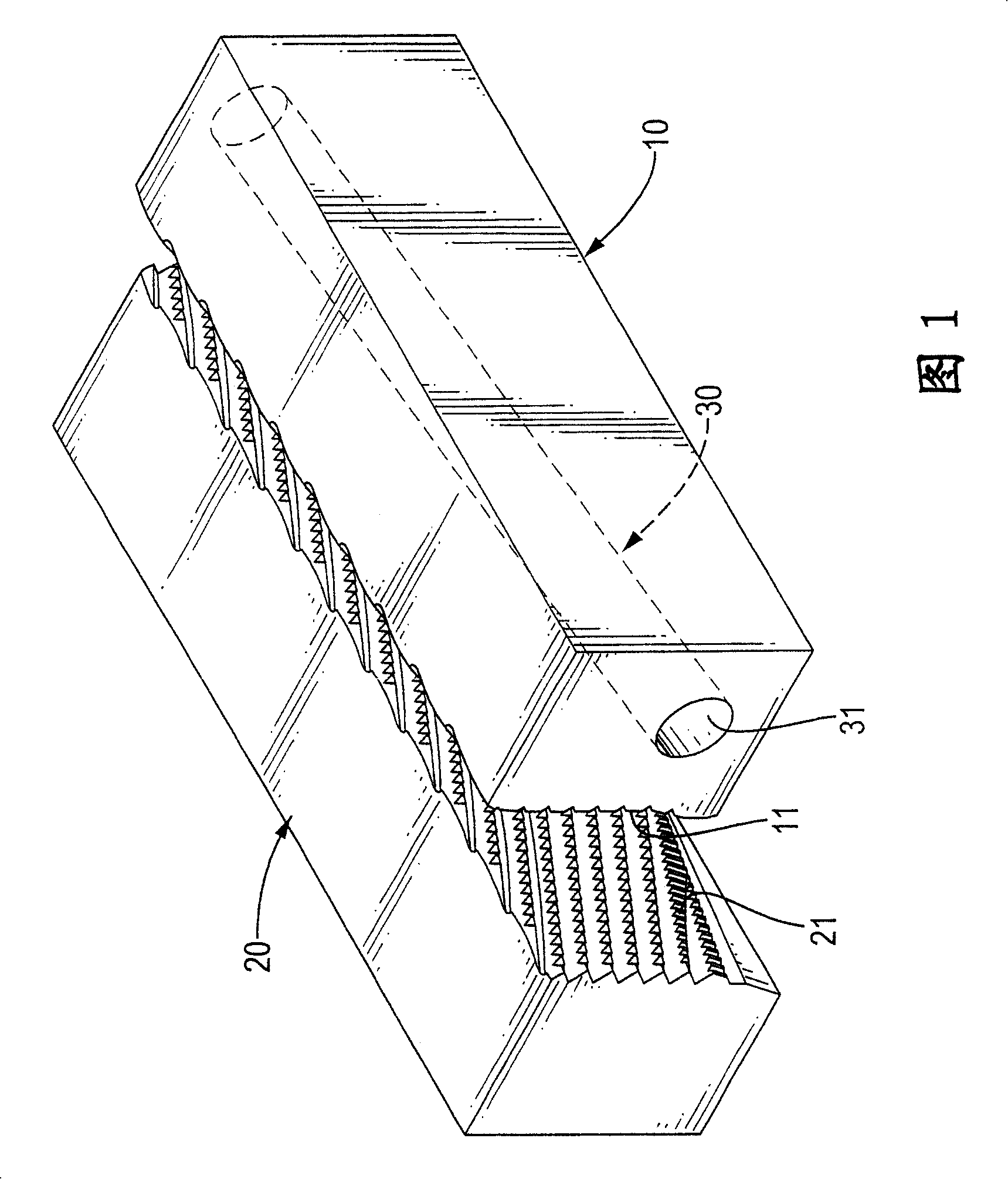

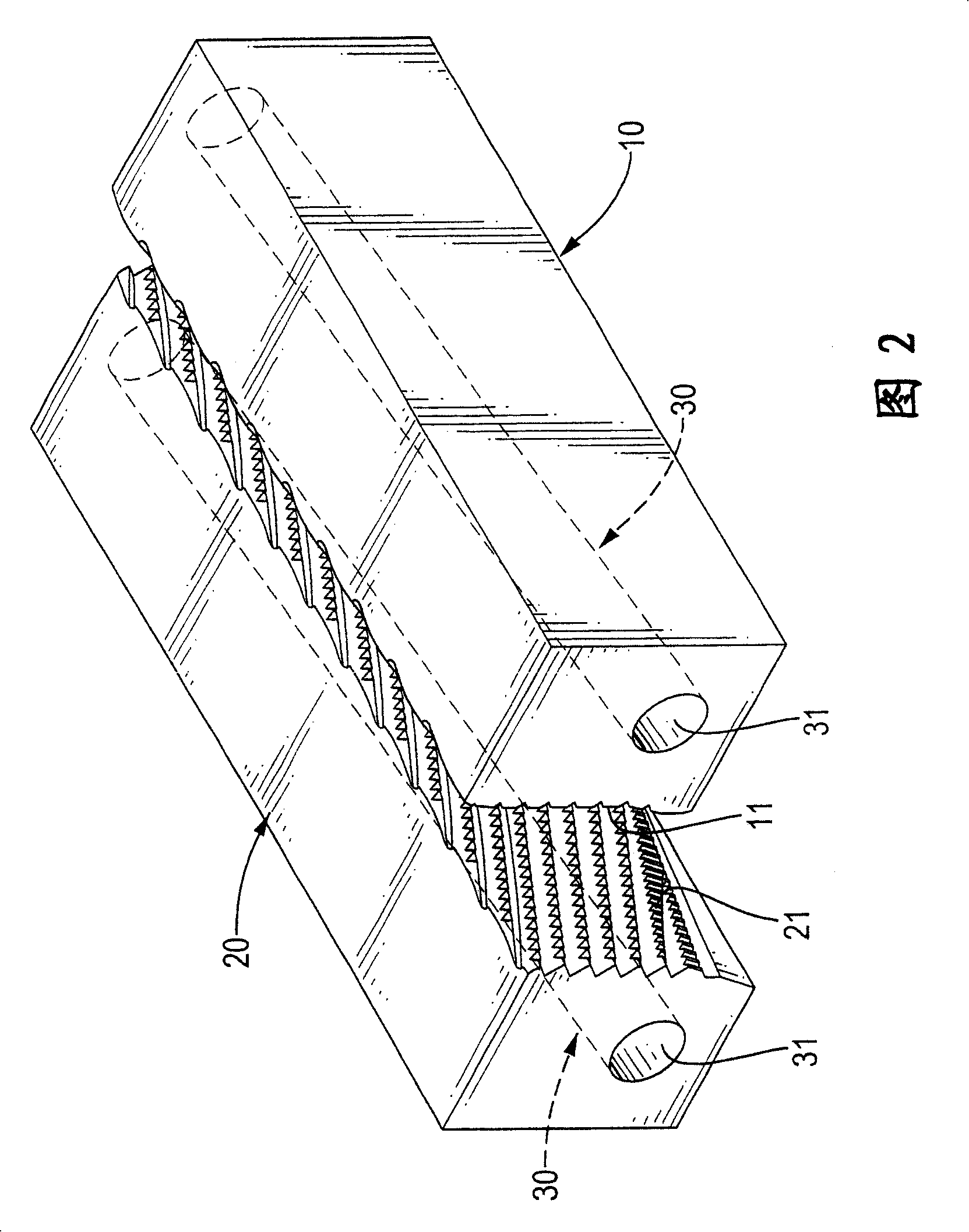

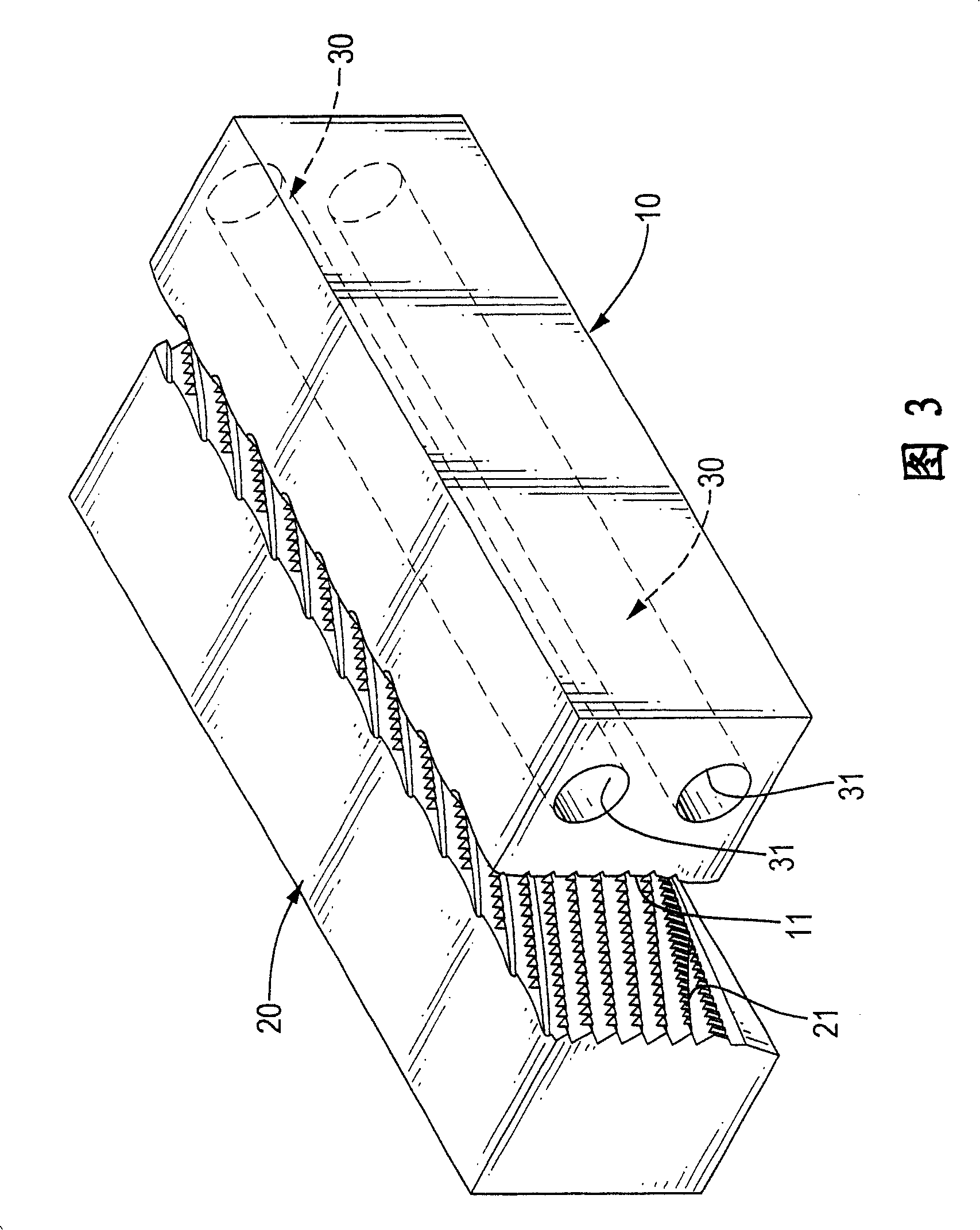

[0021] As shown in Fig. 1, the screw rubbing die set with cooling function of the present invention includes a fixed die 10 and a movable die 20, wherein the fixed die 10 is a strip-shaped plate body, one of which The side has a tooth-rubbing action surface 11, and the movable tooth plate 20 is also a long block-shaped plate body, and is arranged parallel to the side of the fixed tooth plate 10 with the tooth-rubbing action surface 11, and the mobile tooth plate 20 A tooth rubbing action surface 21 is provided on a side adjacent to the fixed dental plate 10 . In addition, the screw rubbing die set of the present invention also selects one or both of the fixed die 10 and the movable die 20 to set a refrigerant passage 30 for connecting the cooling cycle system so that the fluid refrigerant flows through the refrigerant passage 30 Medium circulation provides cooling.

[0022] The design of the above-mentioned refrigerant channel 30 includes at least several specific and feasibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com