Low-frequency ultrasonic atomizing cultivator

An ultrasonic atomization and cultivator technology, applied in the field of agricultural engineering, can solve the problems of limiting the amount of atomization, fatigue fracture, increasing the amount of atomization, etc., and achieves adjustable droplet size, high reliability, and large amount of atomization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

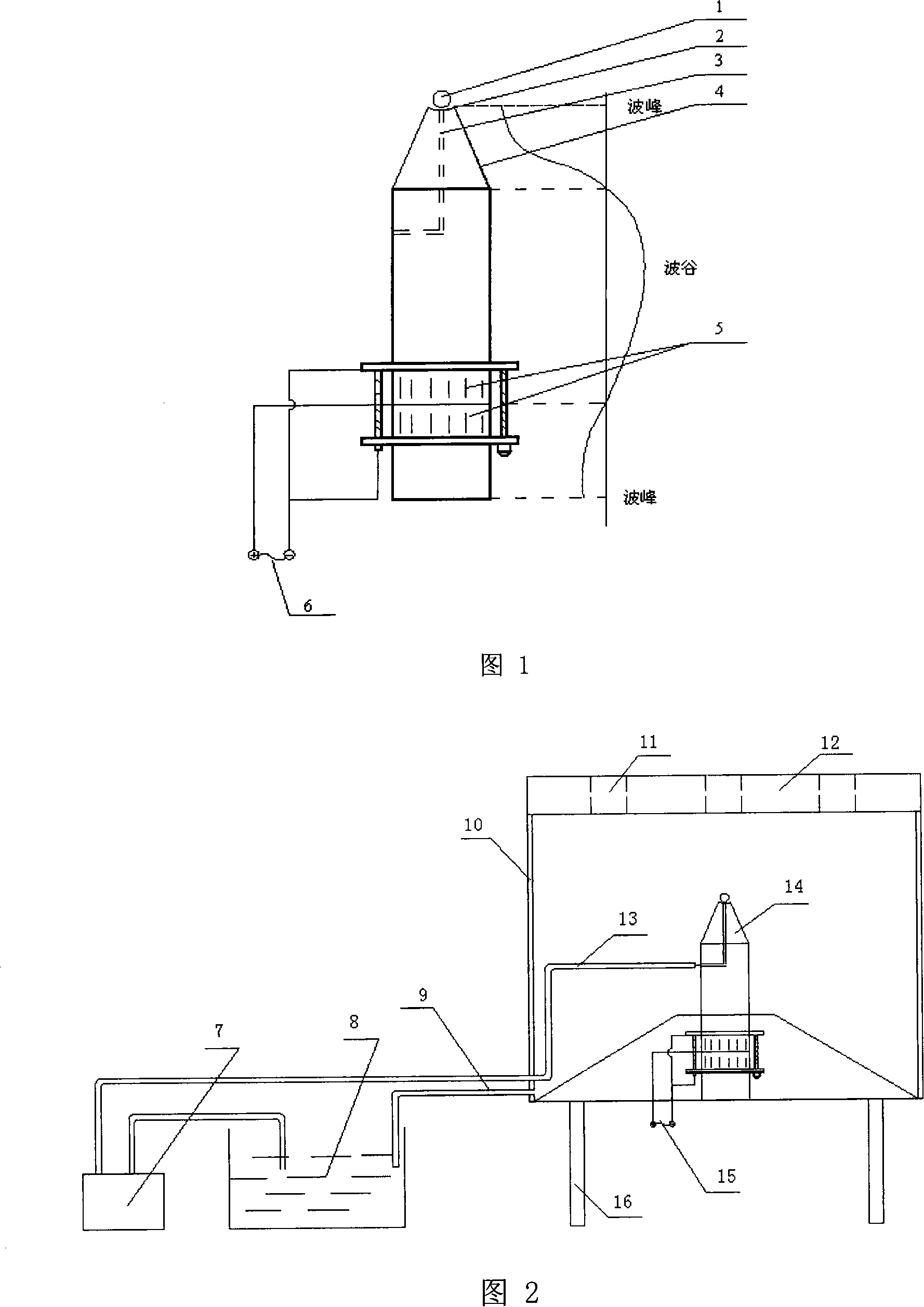

[0020] The present invention is an atomized cultivator developed by using the principle of low-frequency ultrasonic atomization, as shown in Figure 2, it includes a power pump 7, a nutrient solution tank 8, a return pipeline 9, a glass tank 10, a planting hole 11, and a planting plate 12 , Liquid supply pipeline 13, atomizing nozzle 14, etc. One end of the power pump 7 is connected to the nutrient solution tank 9, the other end is connected to the atomizing nozzle 14 through the liquid supply pipeline 13, the bottom of the glass tank 10 is connected to the nutrient solution tank 8 through the return pipeline 9, and the mist pipeline is laid on the bottom of the glass tank 10 and installed The atomizing nozzle 14 that sprays upwards is provided with a planting plate above. For the convenience of observation, a glass tank is used as a cultivation tank for aerosol cultivation. A nutrient solution return hole is left at the slightly lower end of the glass tank for the return and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com