Outside thermal insulation construction method for cement-base lightweight plate outside wall

A technology for external wall thermal insulation and construction method, applied in covering/lining, building, building structure, etc., can solve problems such as waste of raw materials, high thermal conductivity of thermal insulation layer, easy cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

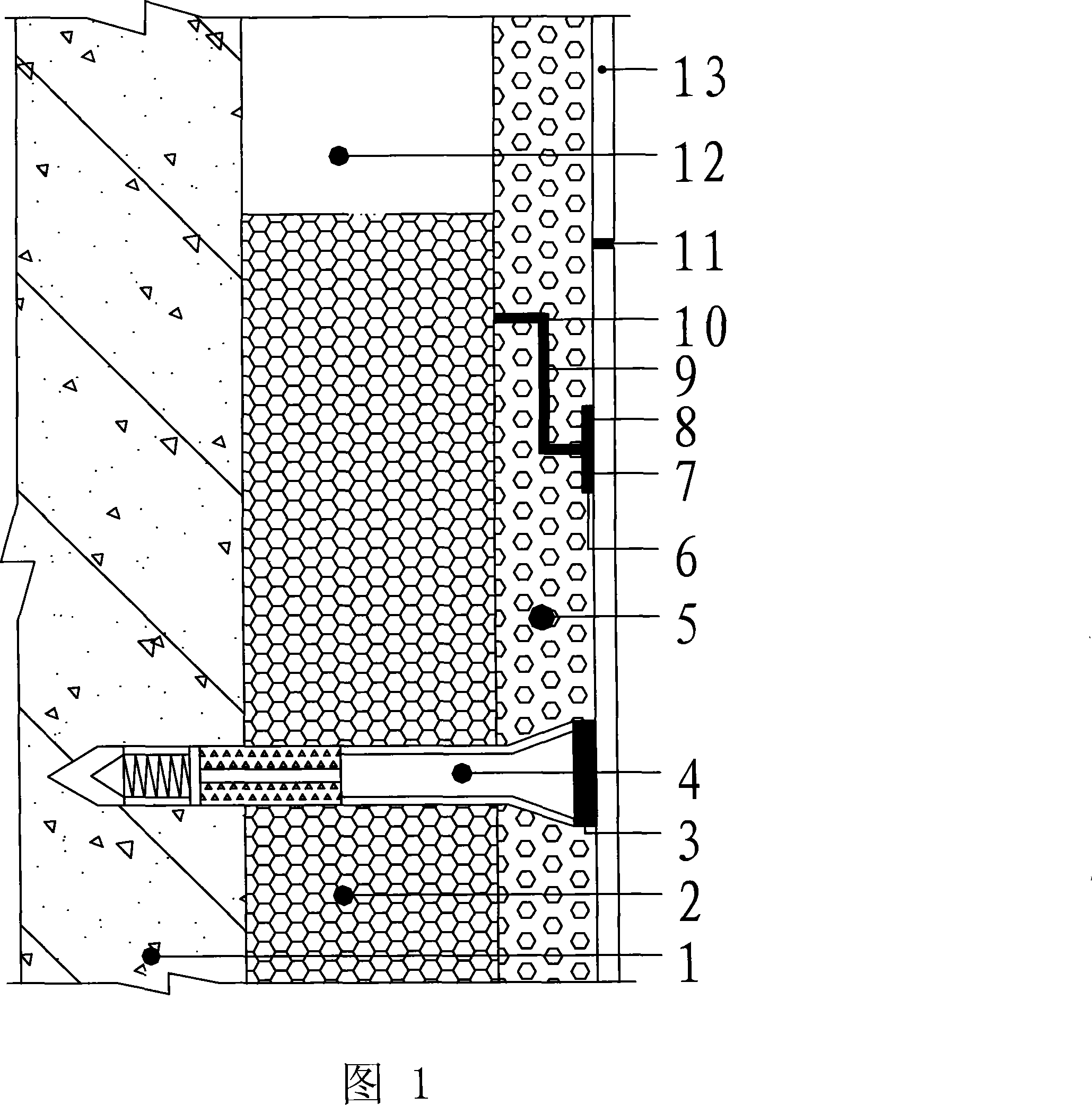

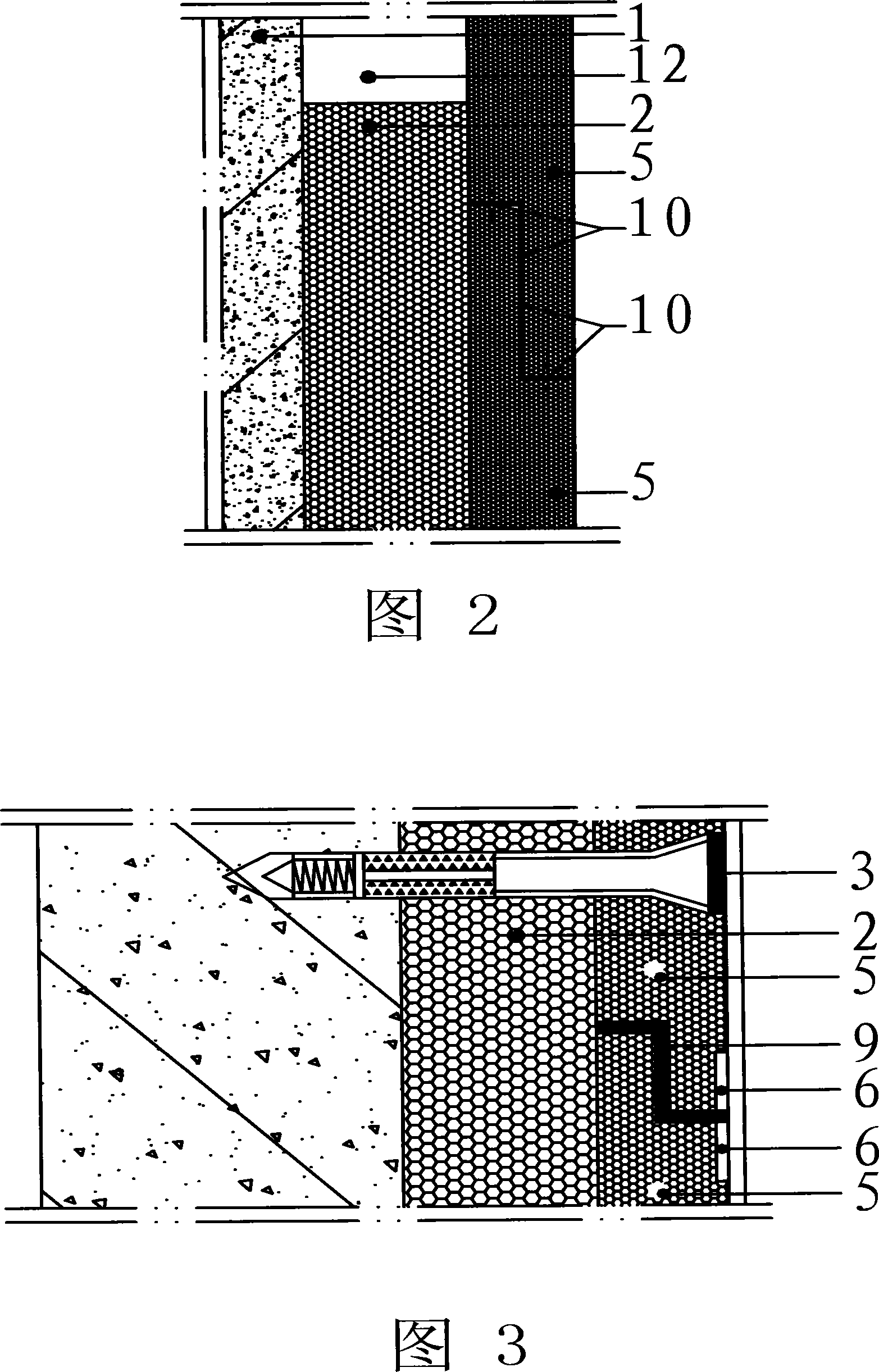

[0005] It contains foamed polyurethane insulation material 2, flexible anti-crack putty of the same material 3, TOX nylon sleeve steel nails 4, cement-based light board 5, groove 6, alkali-resistant mesh cloth 7, flexible anti-crack putty 8, foam Glue 9, L-shaped groove 10, weather-resistant silicone sealant 11, cavity 12, finish 13. In the processing plant, the cement lightweight board 5 is processed into an L-shaped tongue-and-groove 10 falcon connection structure, and the cement lightweight board 5 and the base layer 1 are anchored with TOX nylon sleeve steel nails 4 on site, and a cavity 12 is reserved in the middle, and then The foamed polyurethane insulation material 2 is poured into the reserved cavity 12 to complete the composite connection of anchoring and bonding; the adjacent two cement-based lightweight boards 5 form a positioning reference with their respective L-shaped tongue-and-groove 10 falcon connection structures, and ensure that the external Surface smoothn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com