Automobile wind shield glass mounting method based on automatic glue application and artificial mounting

A glass and gluing technology, applied in the field of anti-error installation, can solve the problems of disturbing the work rhythm of the assembly line, the process is chaotic, and the output is affected, so as to avoid the phenomenon of glass being wrongly installed or unable to be installed, reduce production costs, and improve productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

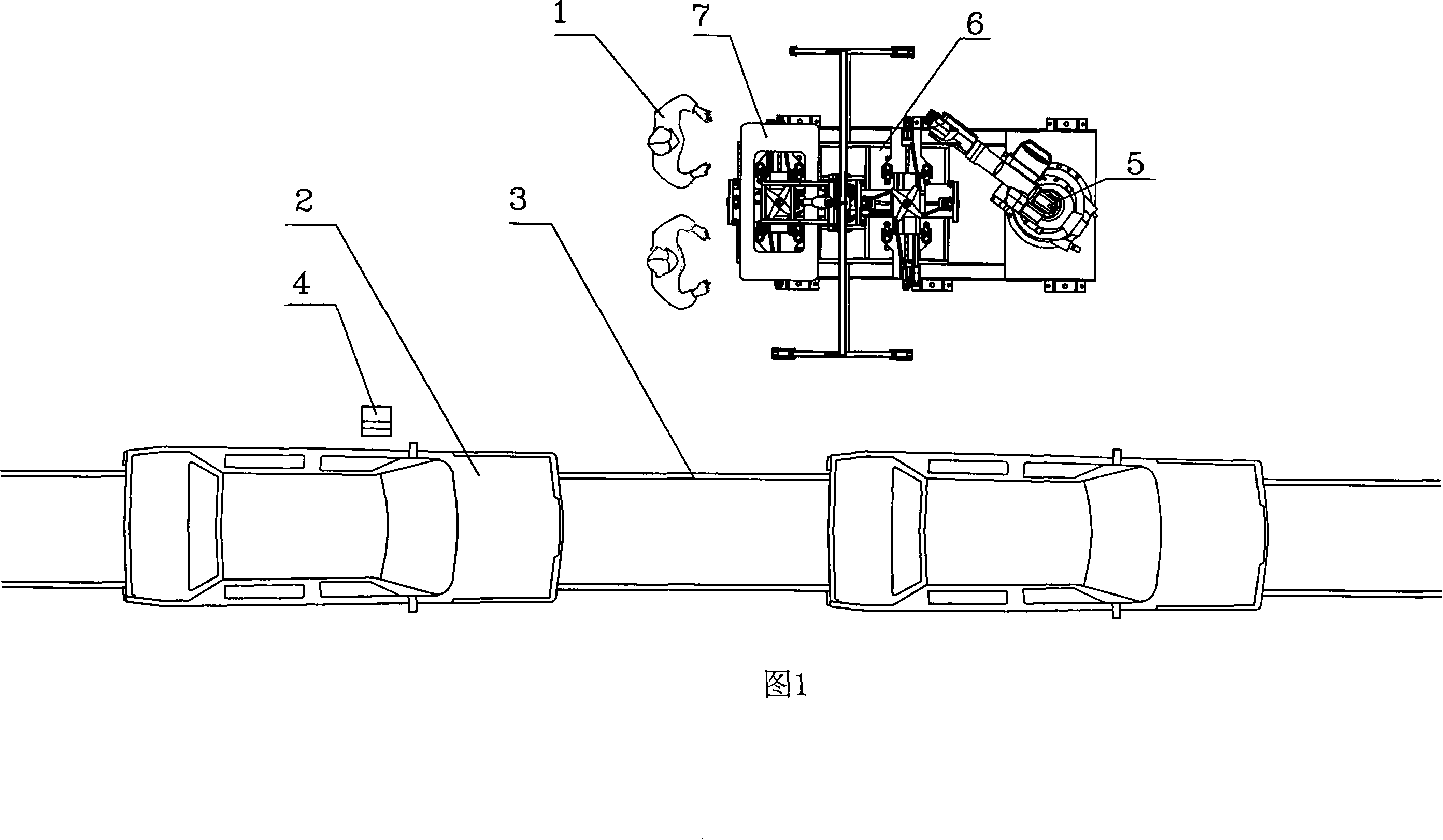

[0027] 1. Establishment of standard database

[0028] Before the system works, input the external characteristics of the glass to be installed in all car models on the assembly line into the system, and establish the shape feature library of standard glass in the form of a two-dimensional array (x i ,y i ). At the same time, input the barcodes of all car shapes on the assembly line into the system, and establish a car model standard database in the form of a one-dimensional string array. Establish a one-to-one correspondence between the car body model and the glass model inside the system.

[0029] 2. System work

[0030] a. After the operator 1 judges the model of the car body 2 on the car body conveying line 3 for the first time, he places the gluing glass 7 on the gluing workstation 6 of the gluing robot 5, and after pressing the start key, the gluing workstation 6 starts testing The external characteristics of the glass placed on the workstation, and then automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com