Special die having movable force plug for the hydraulic forming of outer housing

A hydroforming and punching technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as deformation and scrap parts, and achieve the effects of simple replacement, long mold life and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

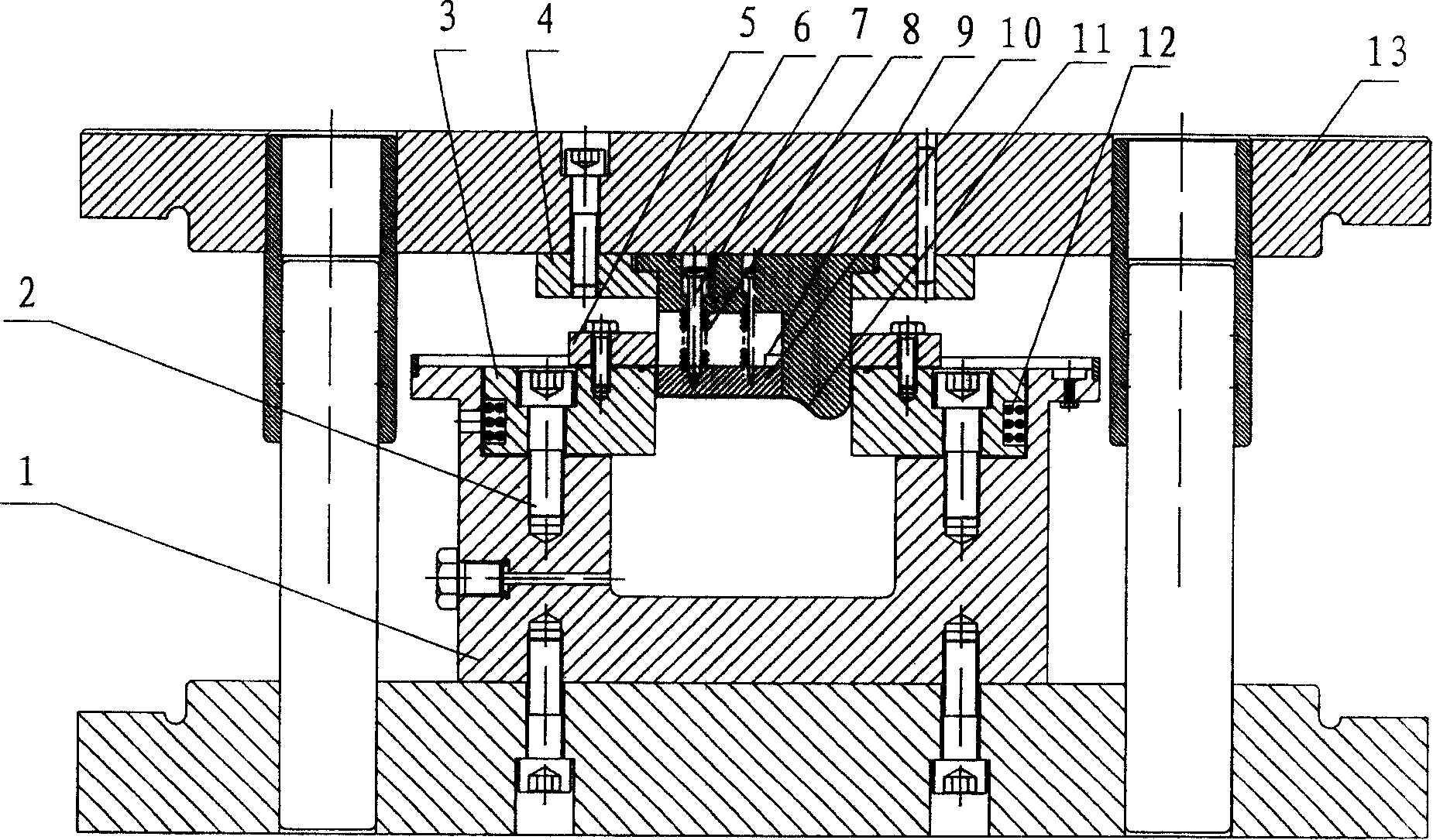

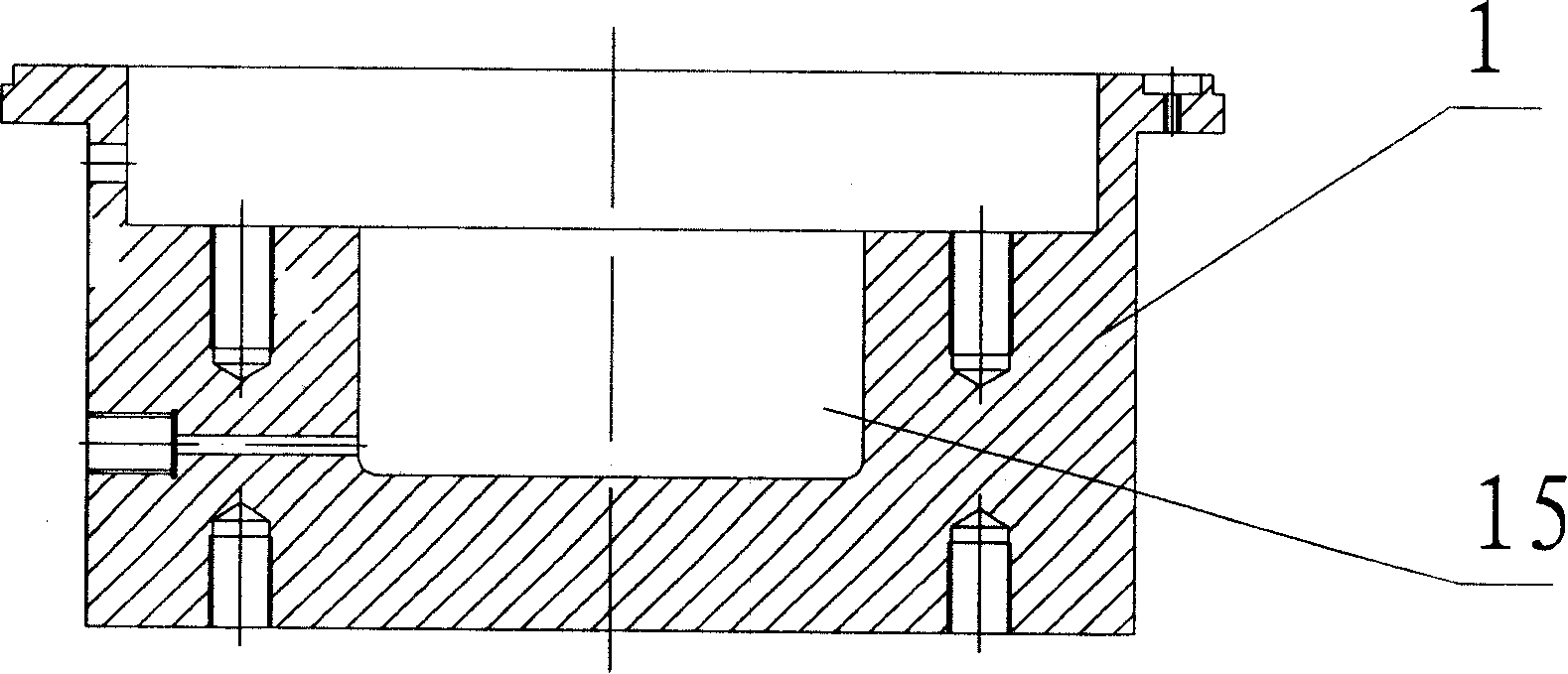

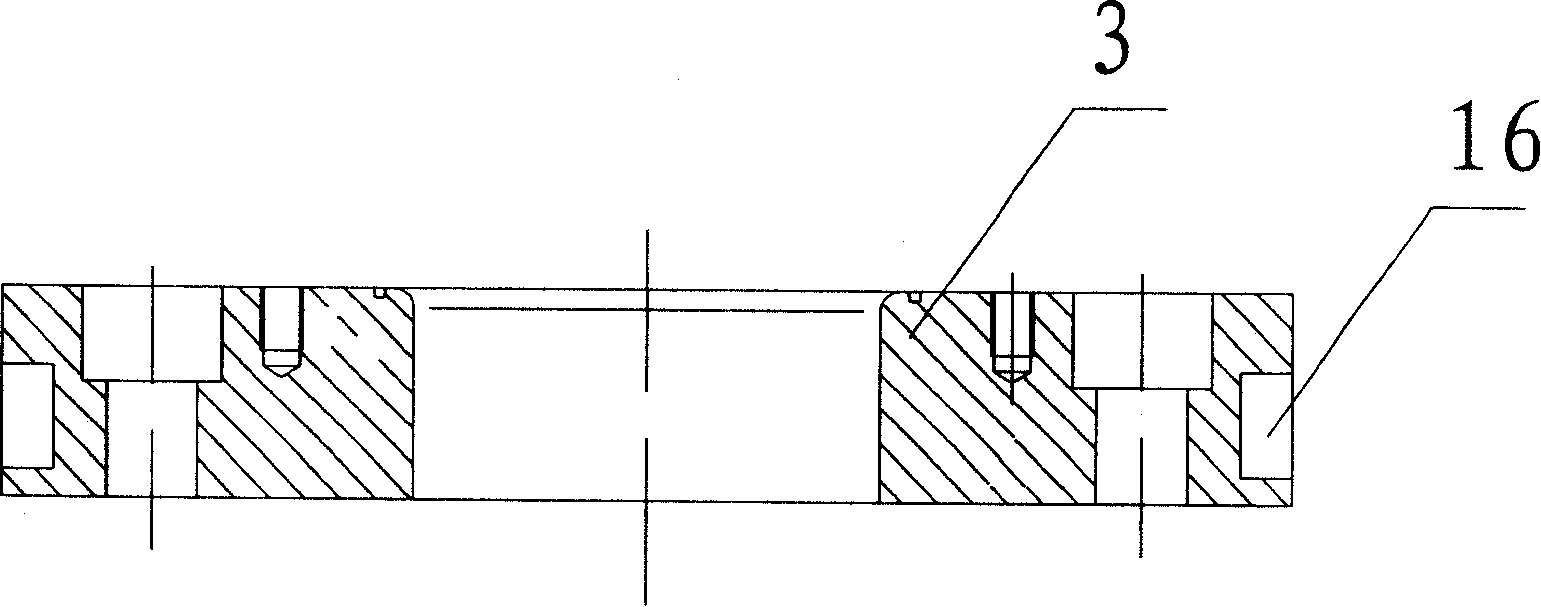

[0025] Such as figure 1 As shown, the magnesium alloy digital camera shell hydroforming special mold with movable punch includes hydraulic chamber 1, bolt 2, die 3, punch fixing plate 4, blank holder 5, fixed punch 6, connecting bolt 7, Spring 8, limit block 9, movable punch 10, blank 11, heating element 12, upper die base 13, etc., hydraulic chamber 1 is connected with die 3 through bolt 2, fixed punch 6, connecting bolt 7, spring 8. The limit block 9 and the movable punch 10 form a block-type combined drawing punch. The fixed punch 6 is fixed on the upper die base 13 through the fixed plate 4. The movable punch 10 is set on the The spring 8 on the connecting bolt 7 is connected with the fixed punch 6, the spring 8 is placed between the fixed punch 6 and the movable punch 10, and the movable punch 10 passes through the wedge-shaped groove 14 on it along the side wall of the fixed punch. The wedge-shaped slideway 17 moves up and down, and its position is controlled by being i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com