Hydrogen-generating material and process for producing the same

A manufacturing method and technology of metal powder, which can be used in the production of hydrogen, fuel cells, electrochemical generators, etc., and can solve the problems of poor affinity and wettability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

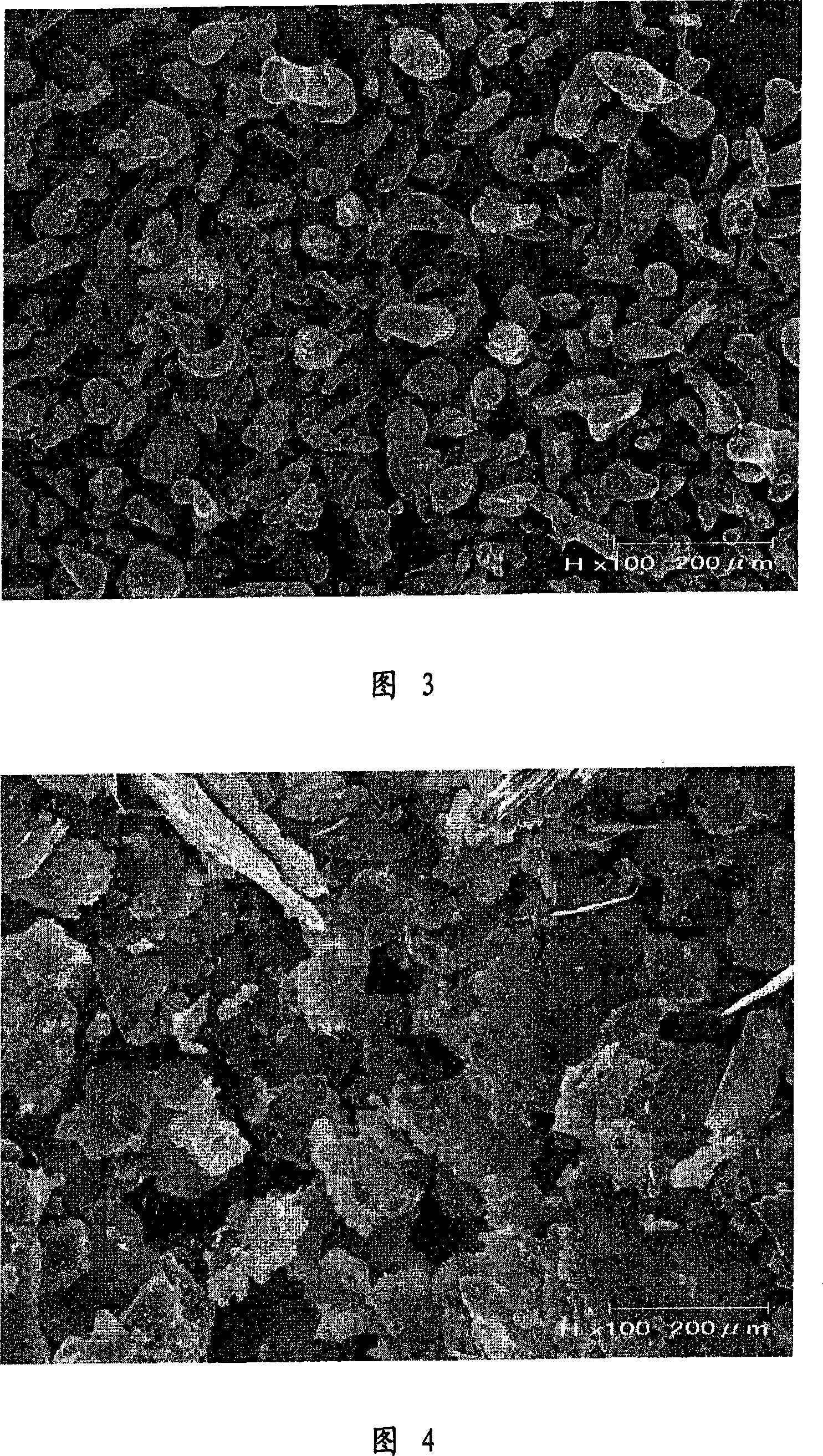

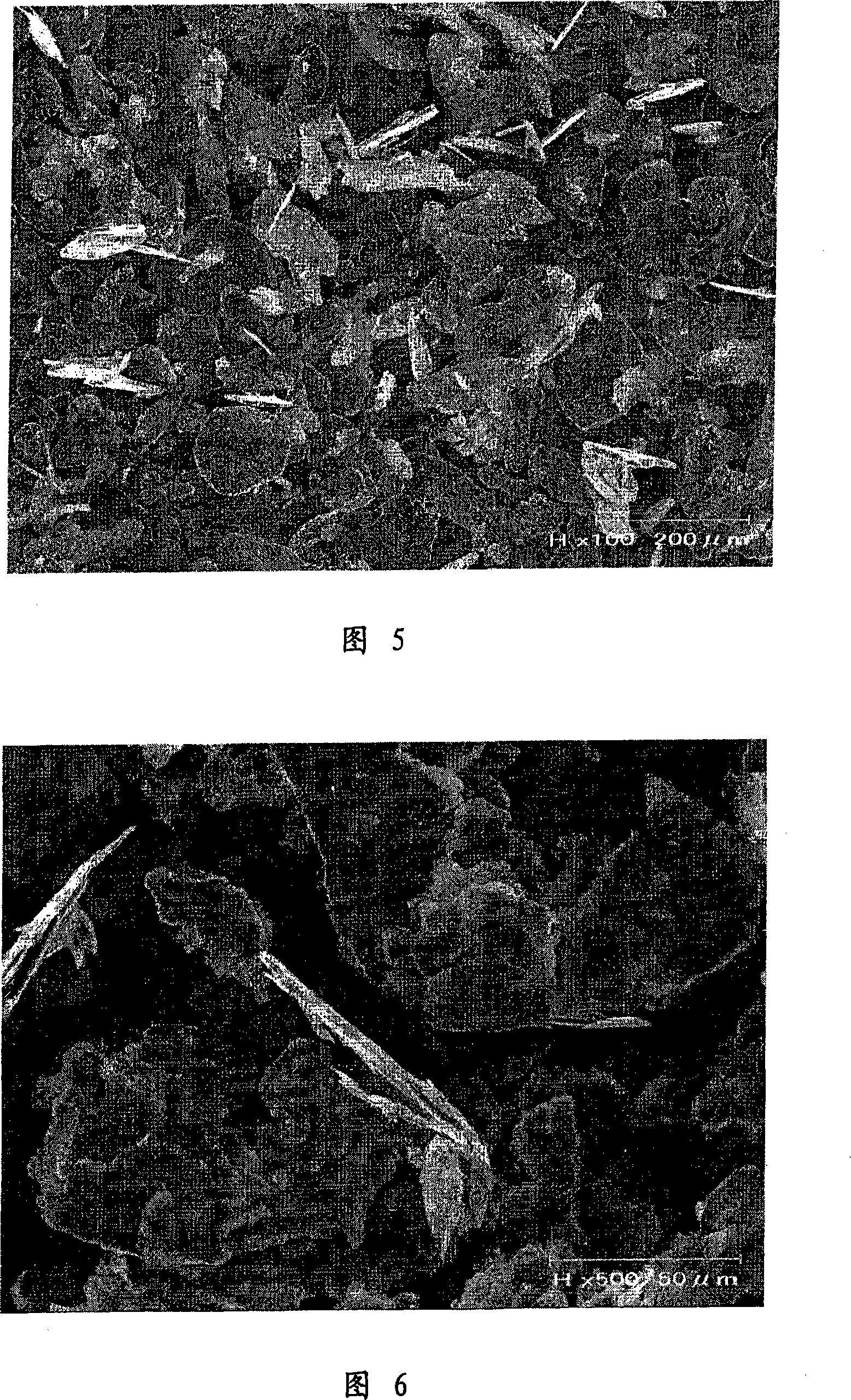

[0072] The average particle size produced by the spray method is 55μm, and the BET specific surface area is 0.6m 2 6g of aluminum powder per gram and 18g of an organic solvent corrosive to aluminum shown in Table 1 below are put into a pulverization container together with particles made of zirconia, placed in a planetary ball mill, and the container is rotated at a speed of 200rpm. Rotate for 1 hour to pulverize the aluminum powder. Thereafter, the solvent was removed by drying under reduced pressure to obtain the target aluminum powder. When the average particle diameter of the pulverized aluminum powder was measured by the laser diffraction / scattering method using "Microtrac HRA" manufactured by Nikkiso Co., Ltd., the value of the 50% particle diameter as the volume-based cumulative fraction was in the tens of tens. μm. In addition, when the specific surface area was measured by the BET method using "Macsorb HM model-1201" manufactured by Mauntec Co., Ltd., the specific s...

Embodiment 2

[0094] Aluminum was pulverized in the same manner as in Example 1, except that methanol and toluene were mixed as a processing solvent in the content ratio shown in Table 3, and the container was rotated for 70 minutes using 18 g of the processing solvent, and the average particle diameter of the obtained powder was measured. In addition, the amount of hydrogen generation and the maximum hydrogen generation rate were obtained by the same method as in Example 1. The results are shown in Table 3.

[0095] [table 3]

[0096] The ratio of methanol and toluene in the processing solvent

[0097] As the processing solvent used in the pulverization step, in methanol as an organic solvent corrosive to aluminum, when adding toluene as an organic solvent inert to aluminum and mixing the solvent for use, hydrogen can be efficiently generated, 95% to 97% of the theoretical value of hydrogen generation can be produced.

Embodiment 3

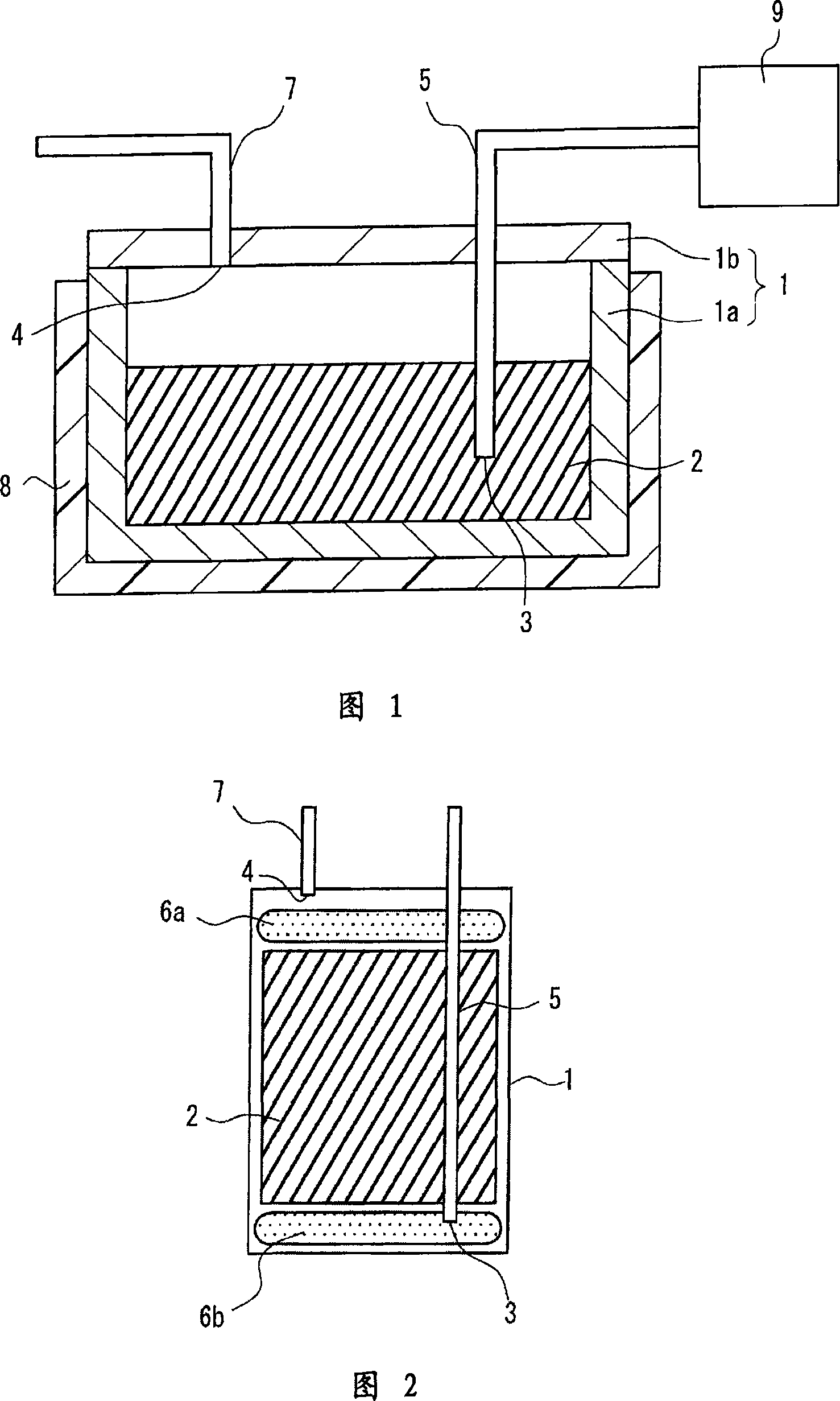

[0099] Using the hydrogen generator shown in Fig. 1, hydrogen is generated in the following procedure. Aluminum powder was prepared in the same manner as in Example 1 using methanol as an organic solvent. 3.2 g of the aluminum powder, α-Al as a reaction accelerator 2 o 3 0.24 g of powder and 0.52 g of calcium oxide as an exothermic material are mixed together as a hydrogen generating material, and they are put into a container body 1a and a lid 1b made of aluminum with an inner volume of 9 cm. 3 The inside of container 1 and seal it. Furthermore, by arranging expanded polystyrene with a thickness of 8 mm as the heat insulating material 8 outside the container 1, a hydrogen generating device having the hydrogen generating material 2 was constructed. Next, water was supplied into the container 1 at a flow rate of 0.023 mL / min through the water supply pipe 5 by the micropump 9 .

[0100] With continuous water supply, the temperature of the container rose slowly, and after 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com