Refrigerator

A technology for refrigerators and storage rooms, applied in the field of refrigerators, can solve the problems of temperature rise, easy mixing of miscellaneous bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

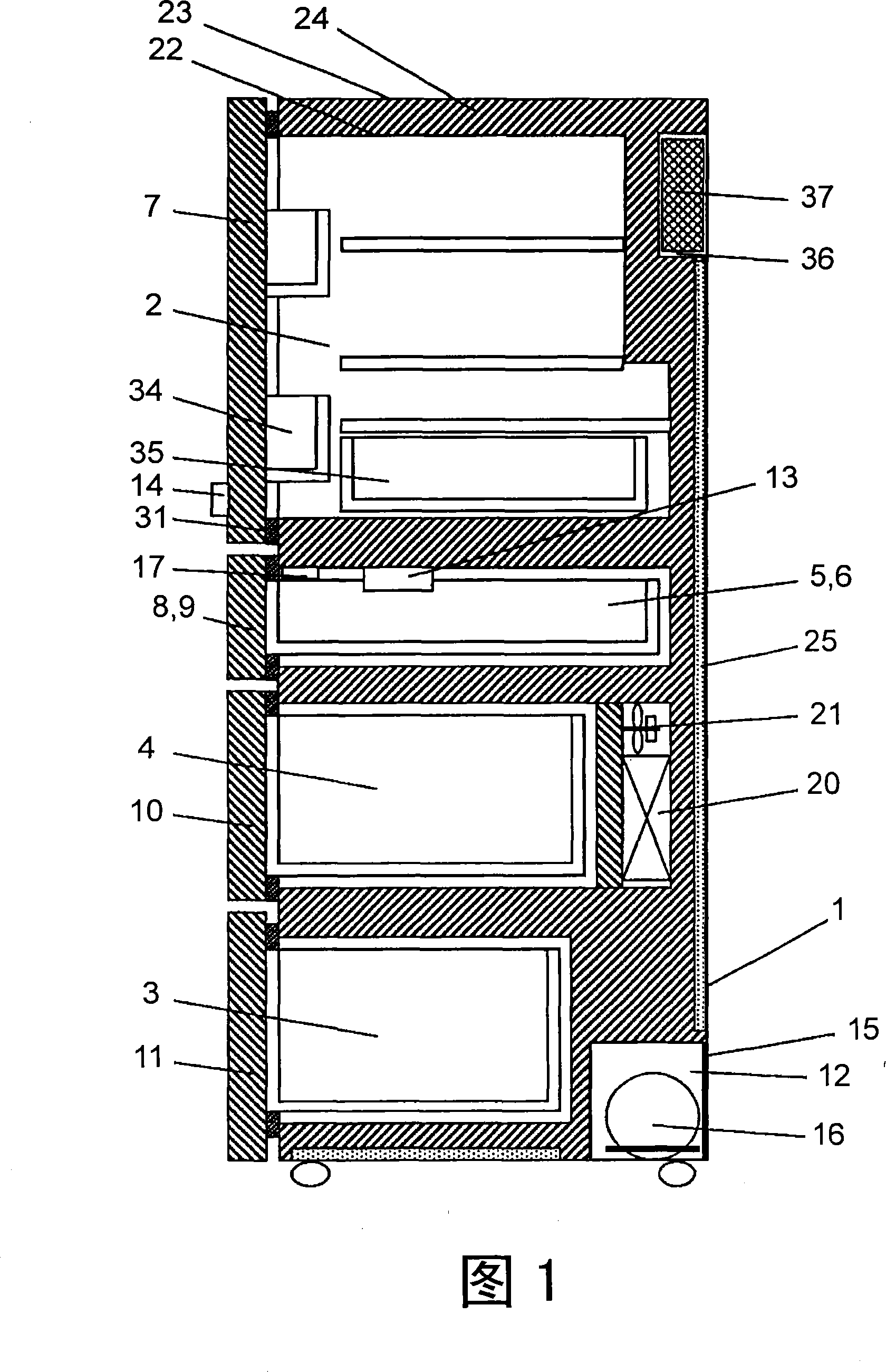

[0048] Fig. 1 is a side sectional view of a refrigerator according to Embodiment 1 of the present invention.

[0049] In FIG. 1 , a refrigerator main body (hereinafter simply referred to as the main body) 1 is equipped with an inner case 22 formed by vacuum-molding a resin body such as ABS and an outer case 23 made of a metal material such as a pre-coated steel plate. The insulation wall made of foam insulation 24. For the foam heat insulator 24, rigid urethane foam, phenol foam, styrene foam, etc. are used, for example. Using hydrocarbon-based cyclopentane as a foaming material is better from the viewpoint of preventing global warming.

[0050] In addition, in the space constituted by the inner case 22 and the outer case 23 before the foam heat insulator 24 is foamed, the vacuum heat insulating material 25 is adhered in close contact with an adhesive member not shown on the outer case side. Moreover, since the vacuum heat insulating material 25 is arrange|positioned in the ...

Embodiment approach 2

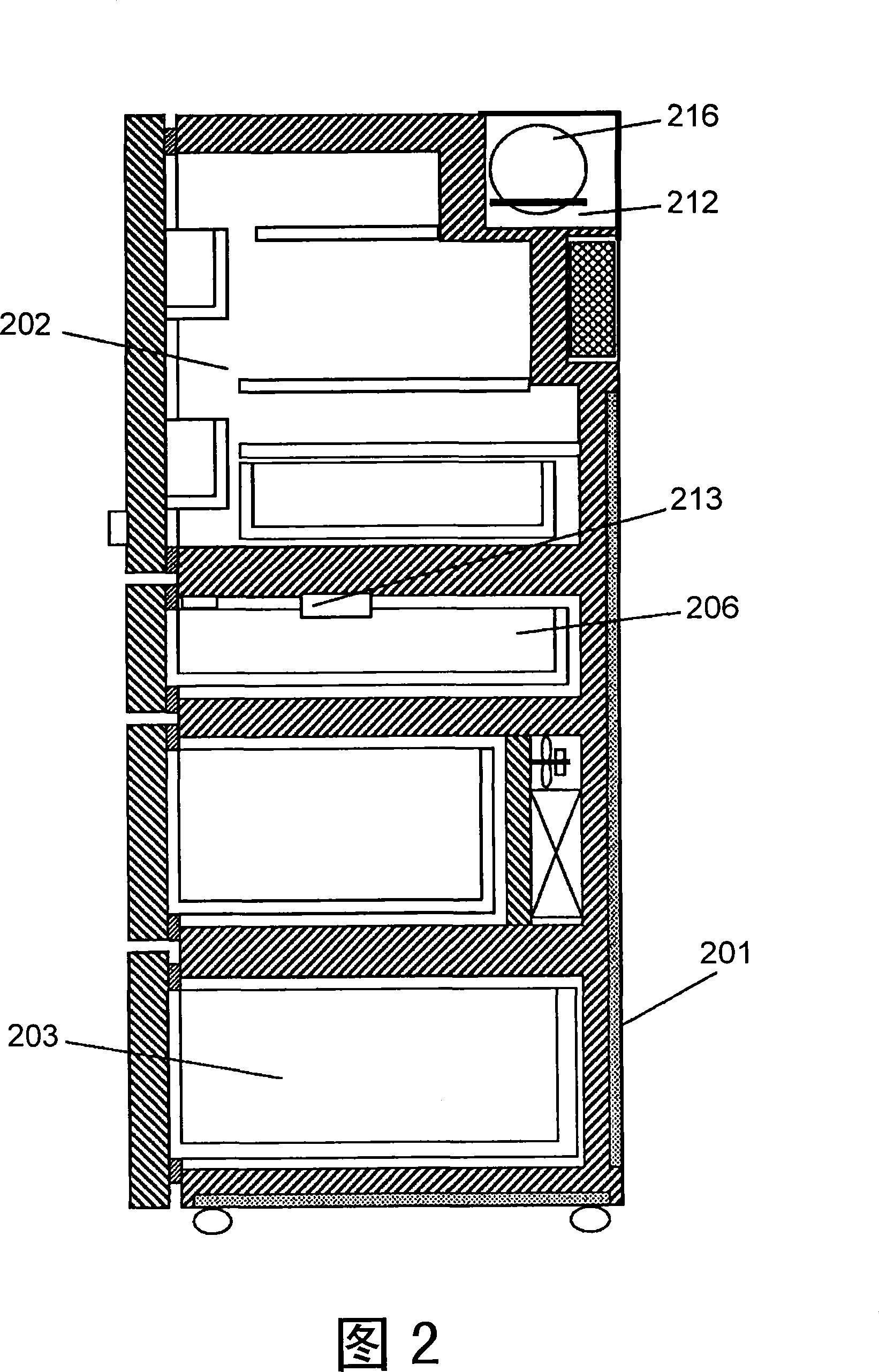

[0077] Fig. 2 shows a side sectional view of a refrigerator according to Embodiment 2 of the present invention.

[0078] In FIG. 2 , the light source 213 is installed in the switching chamber 206. In addition, the machine room 212, which houses the main components of the refrigeration cycle such as the compressor 216 and the unshown condenser, is installed on a side other than the back side of the freezing room 203. Place the backside of the uppermost stage of the refrigerator compartment 202 .

[0079] Conventionally, the machine compartment 212 is located behind the freezer compartment 203 which is the lowermost part of the main body 201. Therefore, the volume of the freezer compartment 203 is reduced. For frozen foods that cannot be accommodated, the switching compartment is often set to be frozen and used as a substitute for the freezer compartment. . By arranging the machine room 212 on the back of the uppermost part of the refrigerator room 202 which cannot be effective...

Embodiment approach 3

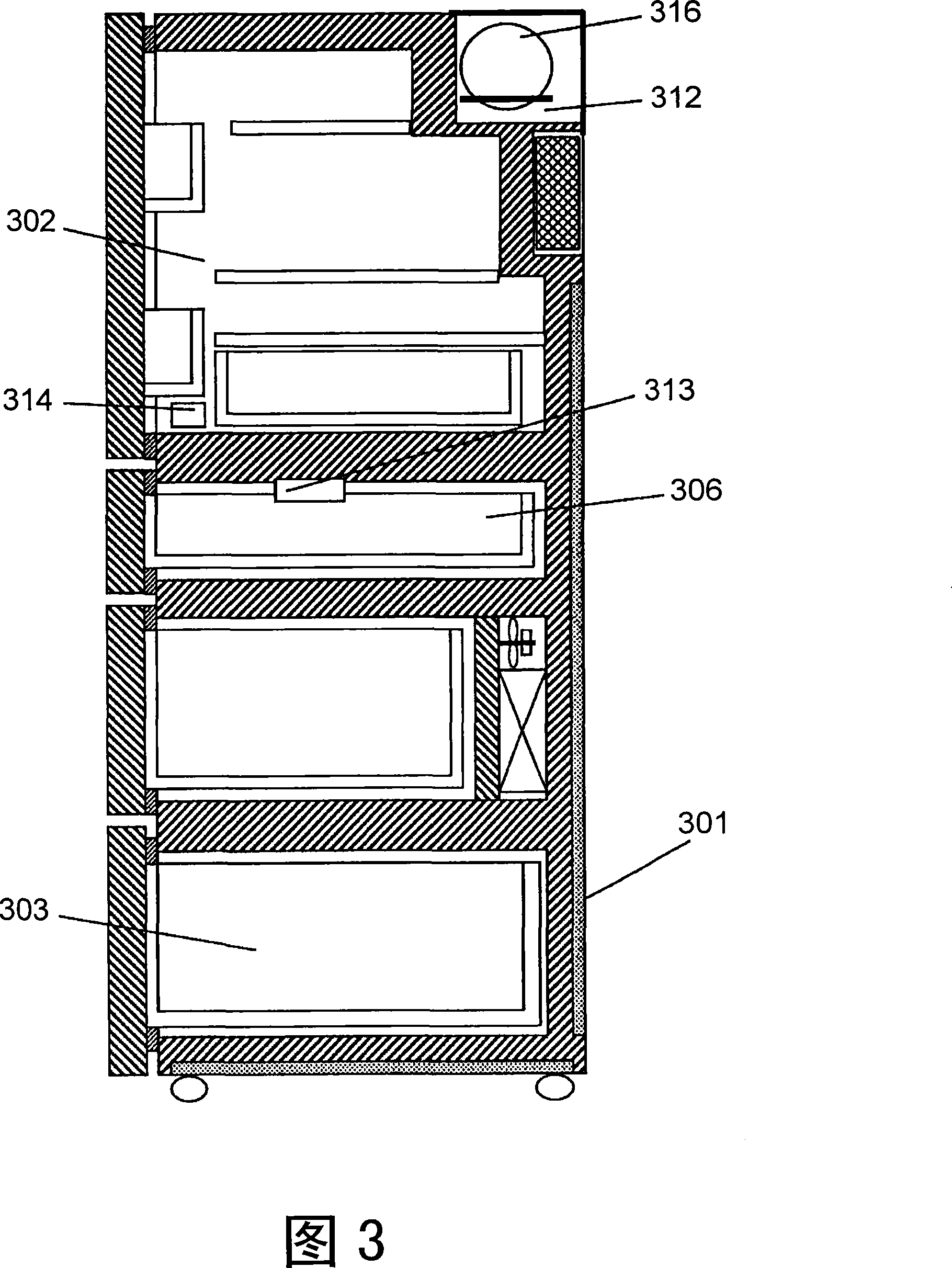

[0083] 3 is a side cross-sectional view of a refrigerator according to Embodiment 3 of the present invention, and FIG. 4 is a cross-sectional view of a light source portion provided in a switch chamber according to Embodiment 3 of the present invention. In addition, FIG. 5 is a graph showing the relationship between the amount of ultraviolet LED irradiation and the number of viable bacteria when fresh salmon according to Embodiment 3 of the present invention were stored for 7 days.

[0084]In the present embodiment, machine compartment 312 housing main components of the refrigeration cycle such as compressor 316 and a not-shown condenser is provided on the uppermost rear of refrigerator compartment 302 other than the rear of freezer compartment 303 . Therefore, a part of the conventional machine room 312 can be utilized as a freezing space. Therefore, the effective compartment volume of freezer compartment 303 can be enlarged without changing the external dimensions. Since th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com