Driving means for combing machine nipper

A driving device and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., to achieve the effect of improving rapid response ability, improving motion accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

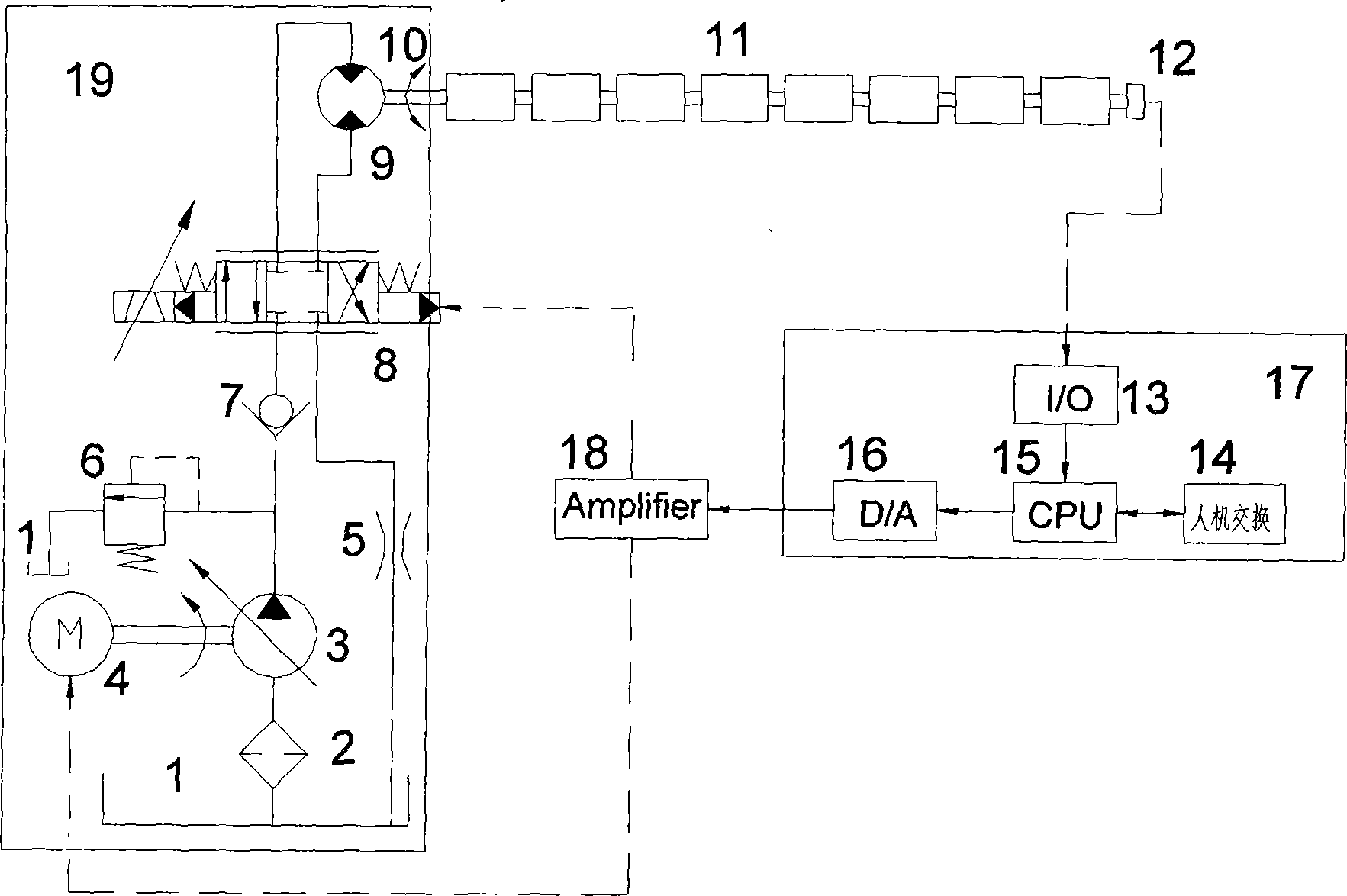

[0011] As shown in the drawings, the present invention includes servo motor 4, open hydraulic system 19, nipper 11, nipper pendulum shaft 10, transmission control system 17 and electronic amplifier 18; described open hydraulic system 19 consists of oil tank 1, Coarse filter 2, one-way variable hydraulic pump 3, throttle valve 5, safety relief valve 6, one-way valve 7, three-position four-way electro-hydraulic servo valve 8 and two-way quantitative hydraulic motor 9, one-way variable hydraulic pump 3 The input end of the servomotor 4 is connected to the output end of the two-way quantitative hydraulic motor 9, and the output end of the bidirectional quantitative hydraulic motor 9 is connected to one end of the nipper pendulum shaft 10, and the other end of the nipper pendulum shaft 10 is connected to the speed sensor 12, and the speed sensor 12 is connected to the transmission control system 17 . The output terminal of the transmission control system 17 is connected to the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com