Scheduling method in silicon chip working process

A technology of processing process and scheduling method, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of low chamber utilization rate, low production efficiency, long average processing time, etc., and achieve chamber utilization rate High efficiency, high production efficiency, and short average processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The scheduling method in the silicon wafer processing process of the present invention is used to schedule the sequence of multiple processing procedures of multiple silicon wafers in the silicon wafer processing equipment, and can also be used to schedule the processing procedures of other equipment.

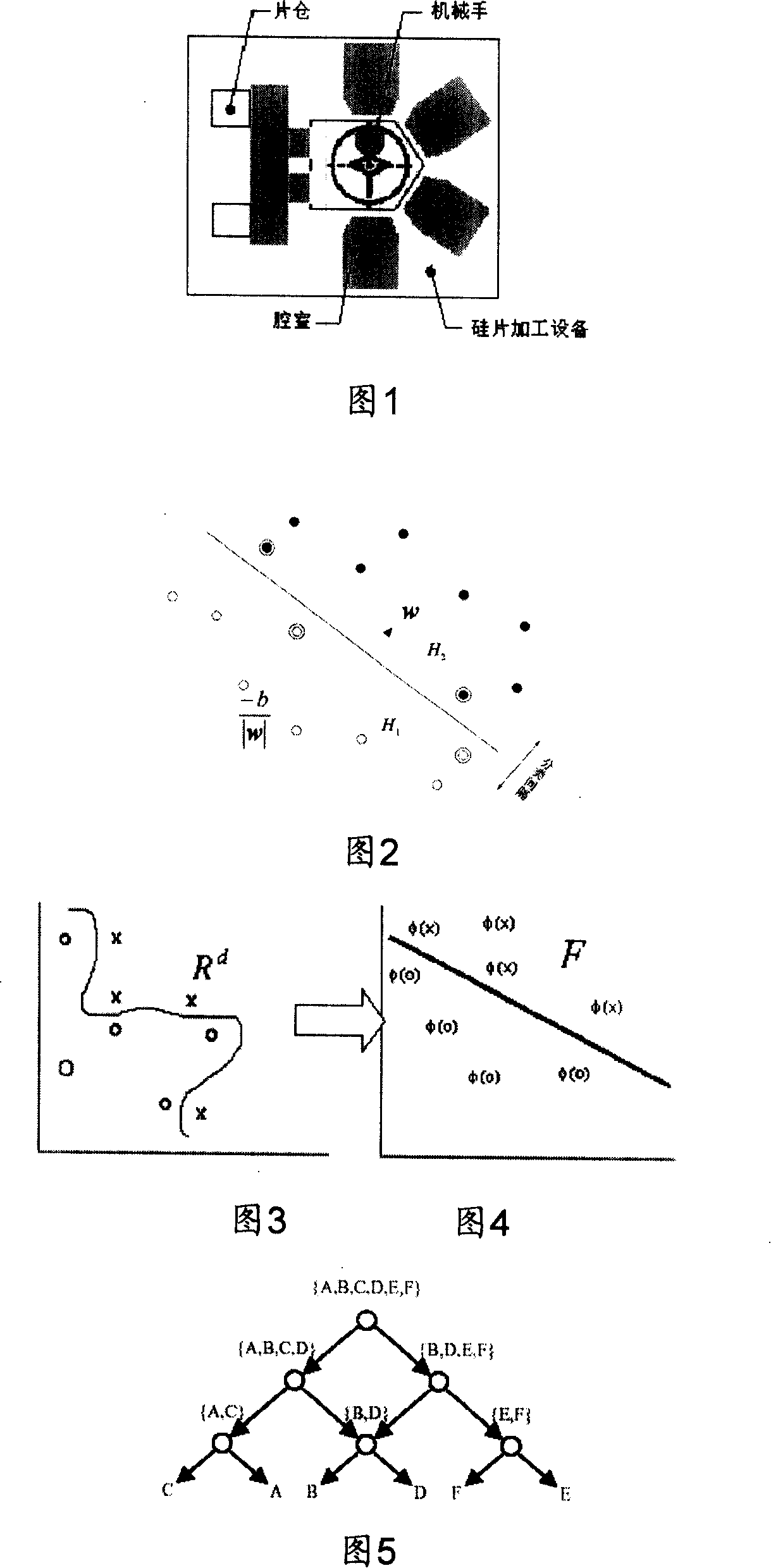

[0039] As shown in Figure 1, the silicon wafer processing equipment includes a magazine, a transfer device and a plurality of chambers, the silicon wafers are processed in the chamber, and the transfer device includes a manipulator for transferring between the magazine and the chamber. Silicon wafers are transported between multiple chambers and among multiple chambers, and the wafer warehouse is used to store silicon wafers in process tasks.

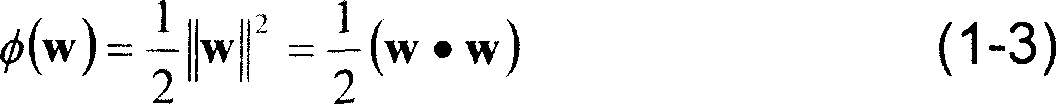

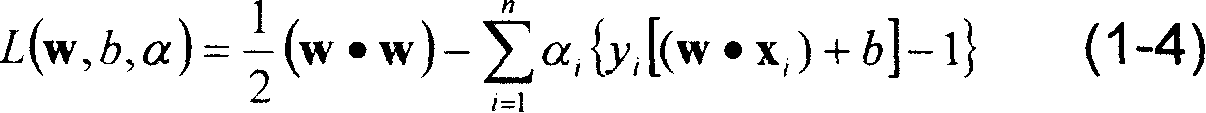

[0040] Its preferred specific implementation method is to schedule in units of procedures. The procedures refer to the processing steps of any silicon wafer in any chamber in a process task. First, multiple procedures are carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com