Oil smoke discharging device with split structure

A split structure, oil fume exhaust technology, applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems that the range hood cannot be discharged, the oil fume gas escapes, and the oil fume cannot be inhaled, so as to achieve all-round absorption of oil fume, Easy and fast installation, the effect of overcoming interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

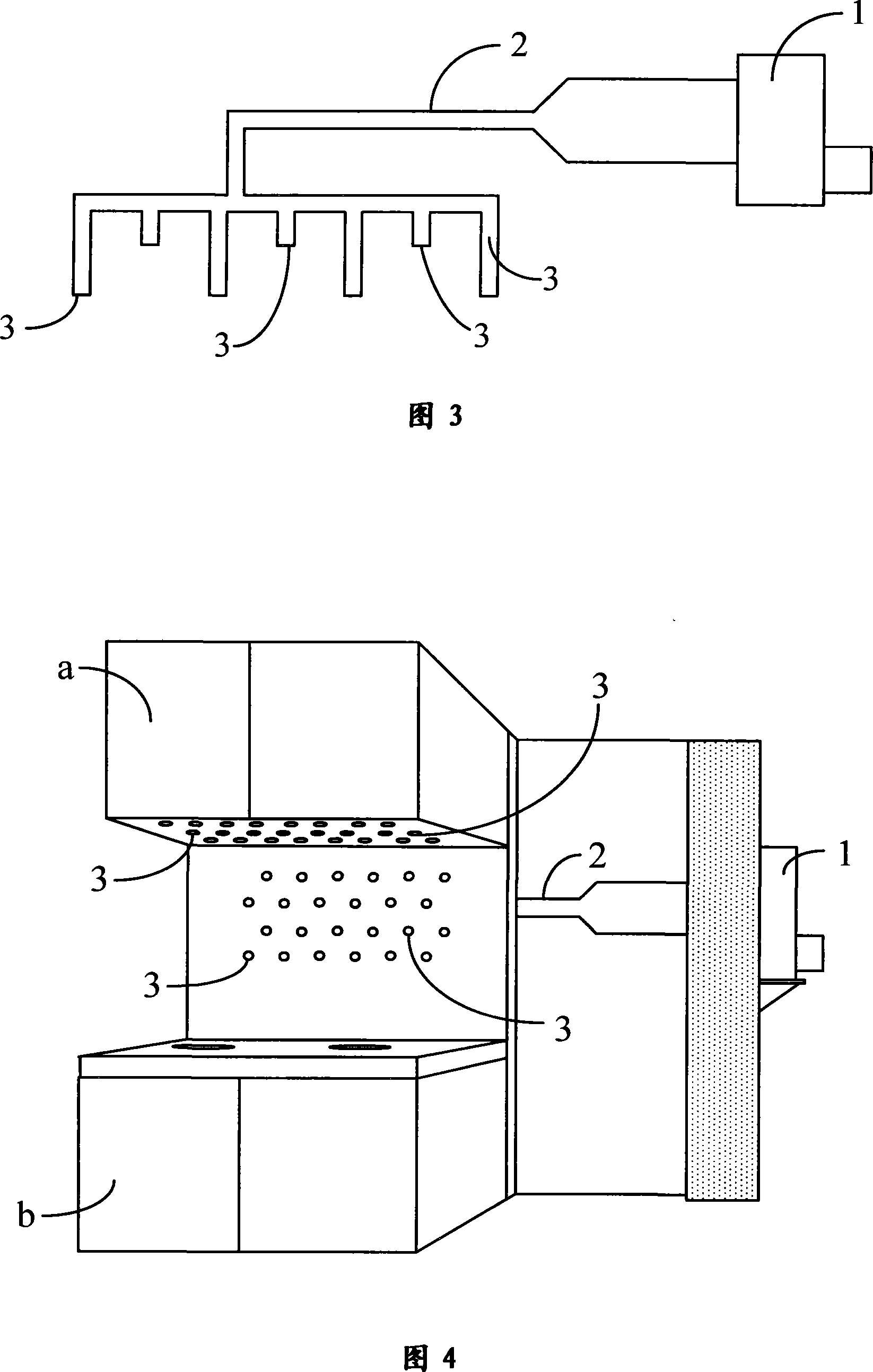

[0053] Fig. 3 shows a schematic diagram of the composition of a specific embodiment of the present invention. It is a split structure fume exhaust device. It includes a blower fan 1 installed outdoors for sucking indoor air, and a variable-diameter exhaust pipe 2 with different diameters at both ends. The variable-diameter exhaust pipe 2 is composed of two sections of pipes with different diameters. The larger end extends out of the room and is connected to the air inlet of the blower fan 1, and the smaller end is connected to the air outlet of the suction part installed indoors for forming local air negative pressure. In this embodiment, the air intake part is composed of a plurality of air intake pipes 3 . One end of each suction pipe 3 is an air outlet, and is jointly connected with the small end of the reduced-diameter exhaust pipe 2 . Each air suction pipe 3 can send the indoor air sucked by the other end into the variable diameter exhaust pipe 2 .

[0054] The variabl...

Embodiment 2

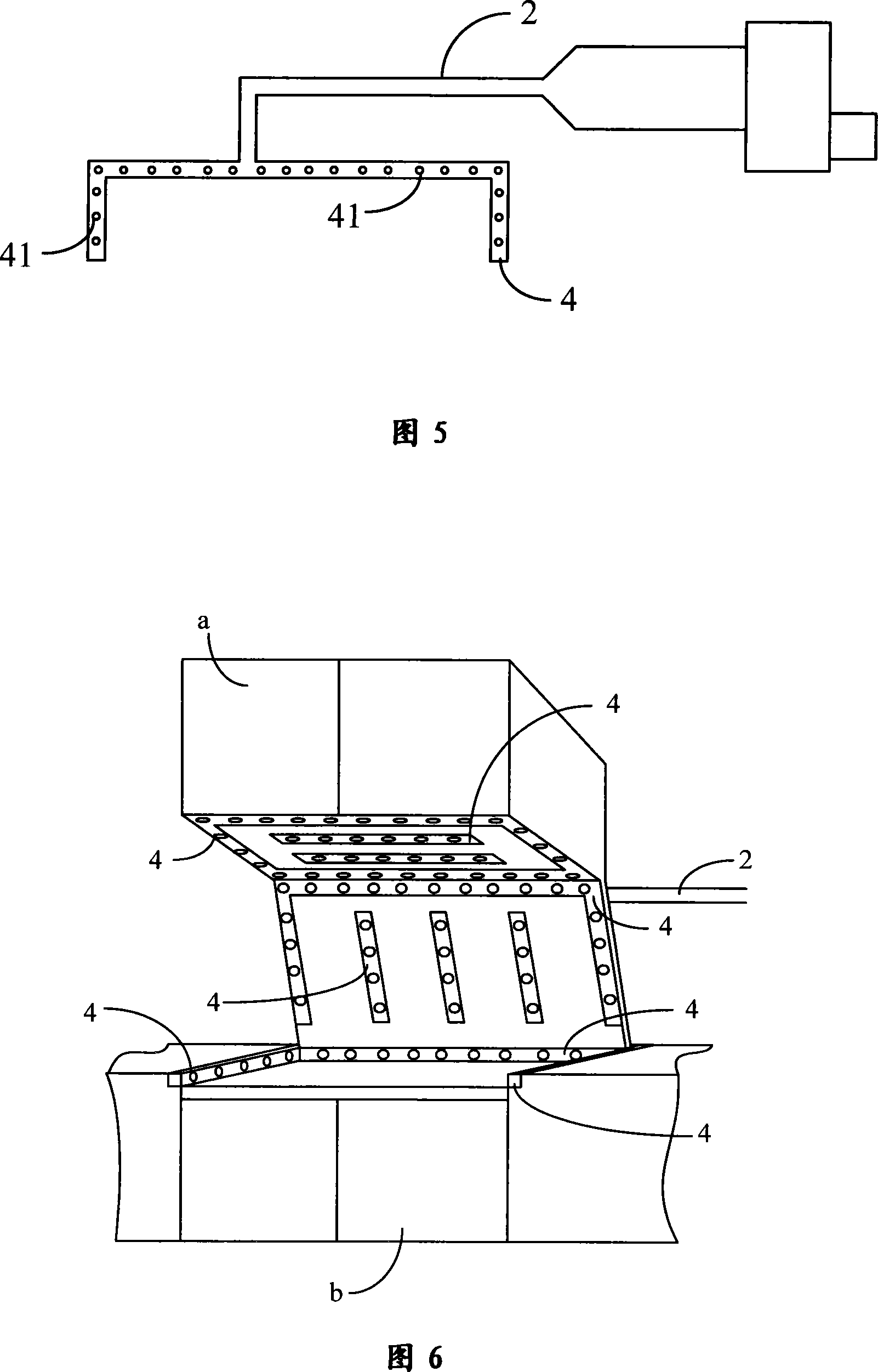

[0057] Fig. 5 is a structural principle diagram of a second specific embodiment of the present invention. In the figure, the suction part is two pipe grooves 4, and the air outlets provided on the two pipe grooves 4 are connected with the reduced-diameter smoke exhaust pipe 2 in the same way as the first embodiment above. A plurality of suction holes 41 are also provided on the two pipe grooves 4 . Proper arrangement of the plurality of suction holes 41 can form a local air negative pressure zone around the pipe slot 4 when the fan 1 is working.

[0058] The shape of the pipe groove 4 can be various, it can be linear, it can also be zigzag, and it can also be annular.

[0059] Fig. 6 shows the oil fume exhaust device that adopts this embodiment together with the stove and the cabinet. In the figure, an annular pipe groove 4 is arranged on the edge of the bottom panel of the cabinet a above the stove b, and two pipe grooves 4 are arranged transversely in the middle. Between ...

Embodiment 3

[0062] Fig. 7 shows another structure of the suction part in the third specific embodiment of the present invention. In the figure, the suction part is a fume exhaust plate 5, which is a plate body, and is provided with a recessed part 51 and an air outlet 52 for sucking indoor air on the surface, and one end of the air outlet 52 is connected to the recessed part. 51 is communicated, and the other end is connected with variable-diameter exhaust pipe 2. The shape of the recessed portion 51 is a rectangle, and any other shape can also be adopted. When the fan is started, the air in the recessed part 51 is sucked out through the variable-diameter exhaust pipe 2, forming a negative air pressure in the recessed part 51. A negative pressure area is formed inside, and the external air flows to this area to form a supplementary pressure airflow, and the oil fume generated in this area cannot spread around, and is sucked by the recessed part 51 and then discharged to the outside.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com