Microwave sensor used for detecting steam humidity

A technology of microwave sensor and steam humidity, which is applied in the direction of using microwave to test moisture content, etc., can solve the problems of small optical measurement window, large non-uniformity of secondary water droplet distribution, measurement result error, etc., and achieve simplified measurement device and simple structure , the effect of high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

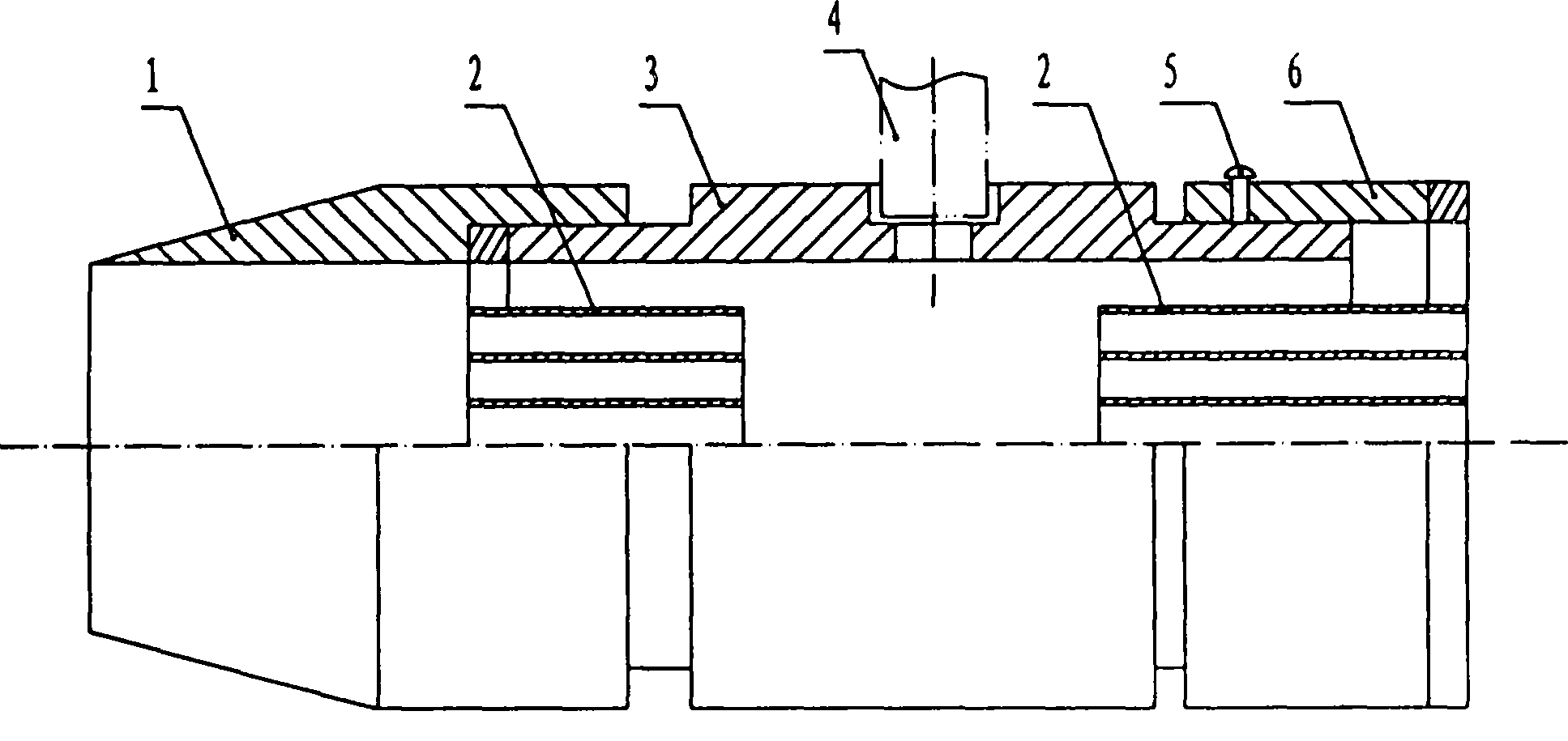

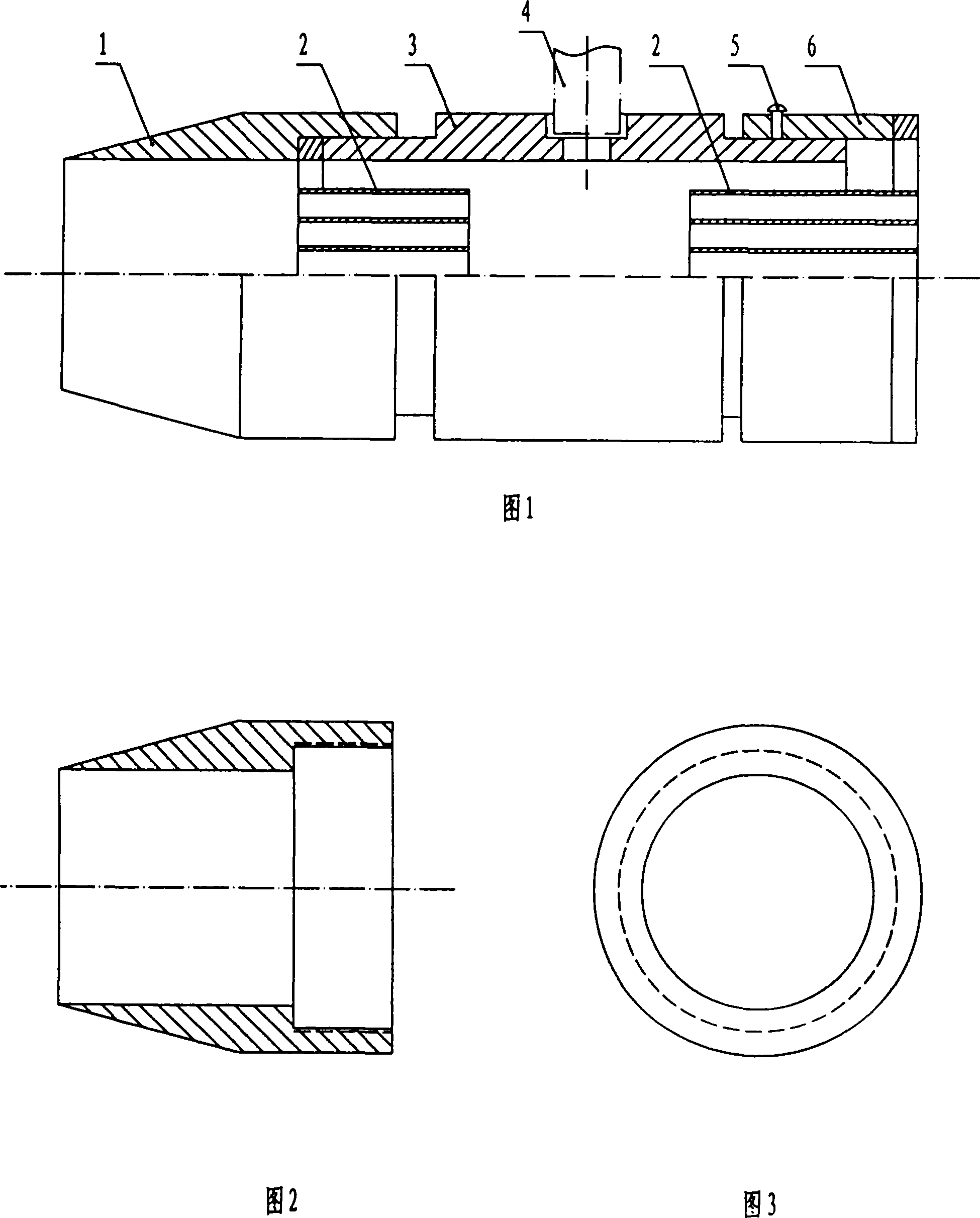

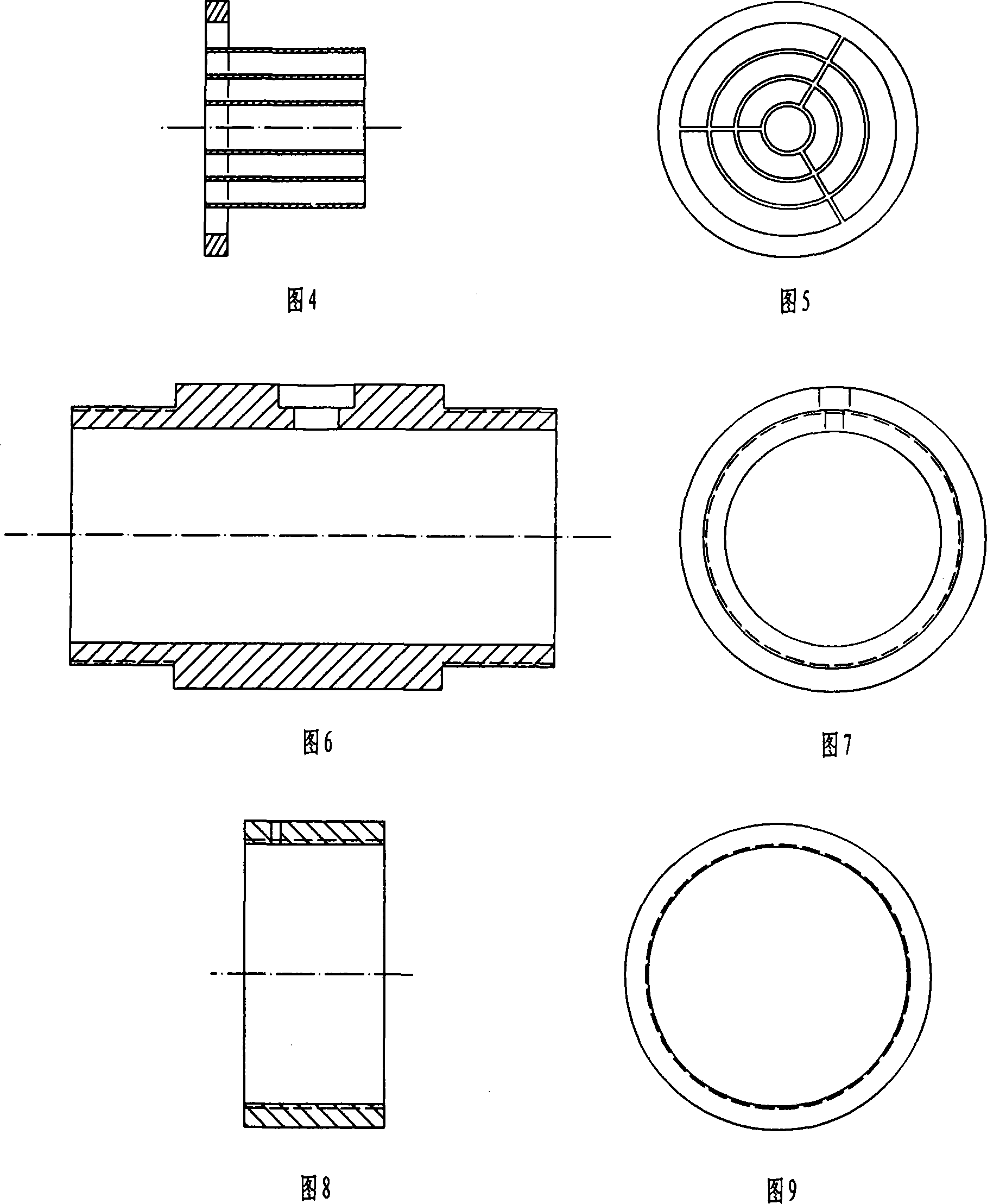

[0030] The change of the dielectric constant of the medium in the microwave resonator will cause the change of the resonant frequency of the resonant cavity. By measuring the change of the resonant frequency of the resonant cavity, the dielectric constant of the medium in the resonant cavity or its variation can be measured. Under a certain pressure (temperature), the humidity of the wet steam is different and the dielectric constant is different, and the two correspond to each other. Therefore, the humidity of the wet steam can be detected by measuring the dielectric constant of the wet steam in the microwave resonator cavity.

[0031] The use of microwave resonant cavity to measure steam humidity is realized by measuring the change of resonant frequency of the resonant cavity when the two-phase flow of wet steam flows through the microwave resonant cavity. In order to make the measurement have high accuracy and precision, it is used to detect wet steam The microwave resonant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com