Bonding by induced high-rate of shear deformation

A technology of bonding fibers and bonding materials, applied in the direction of mechanical processing/deformation, household components, applications, etc., can solve the problems of no target material providing bonding speed and bonding strength, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

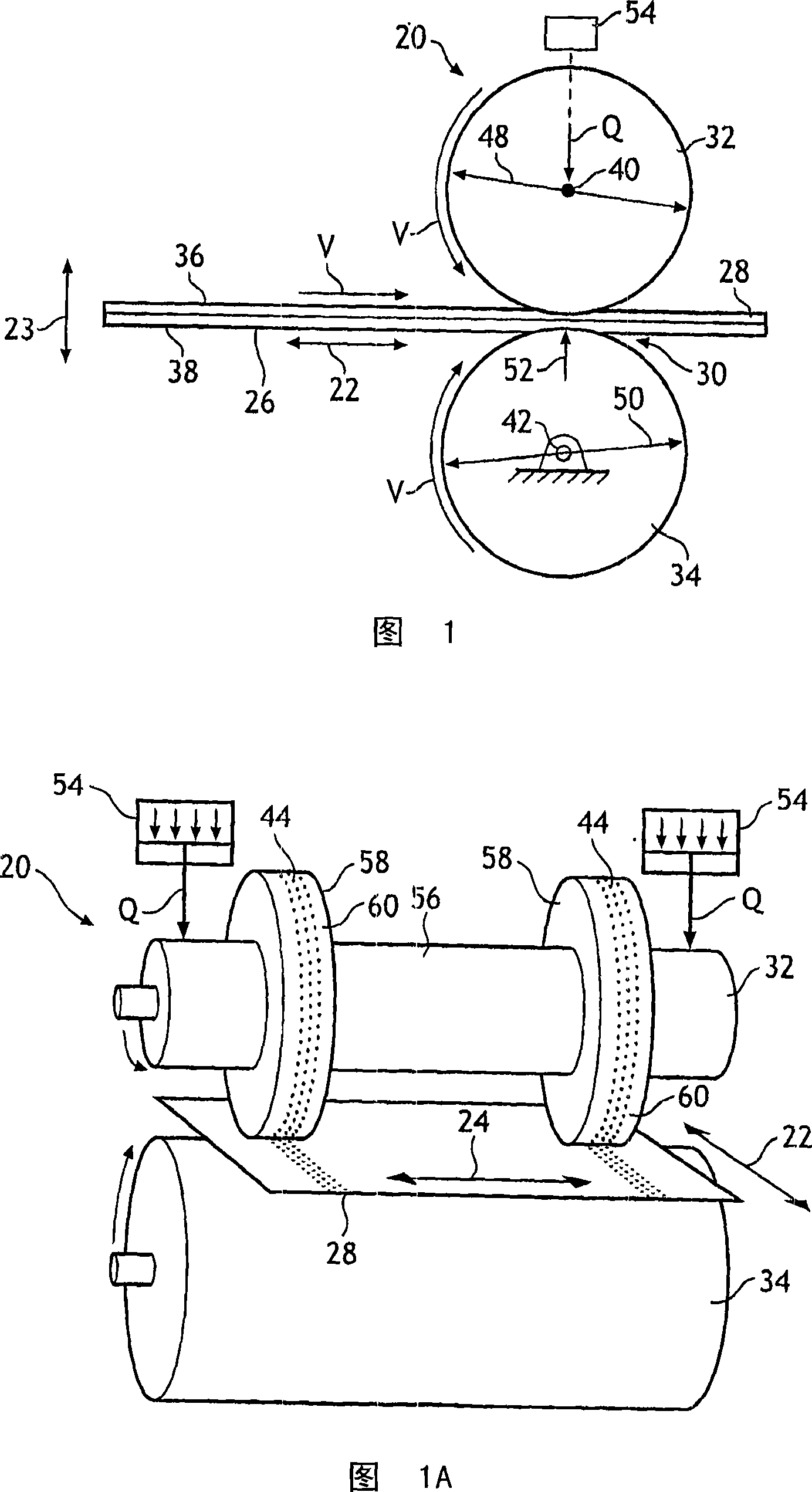

Method used

Image

Examples

Embodiment 2

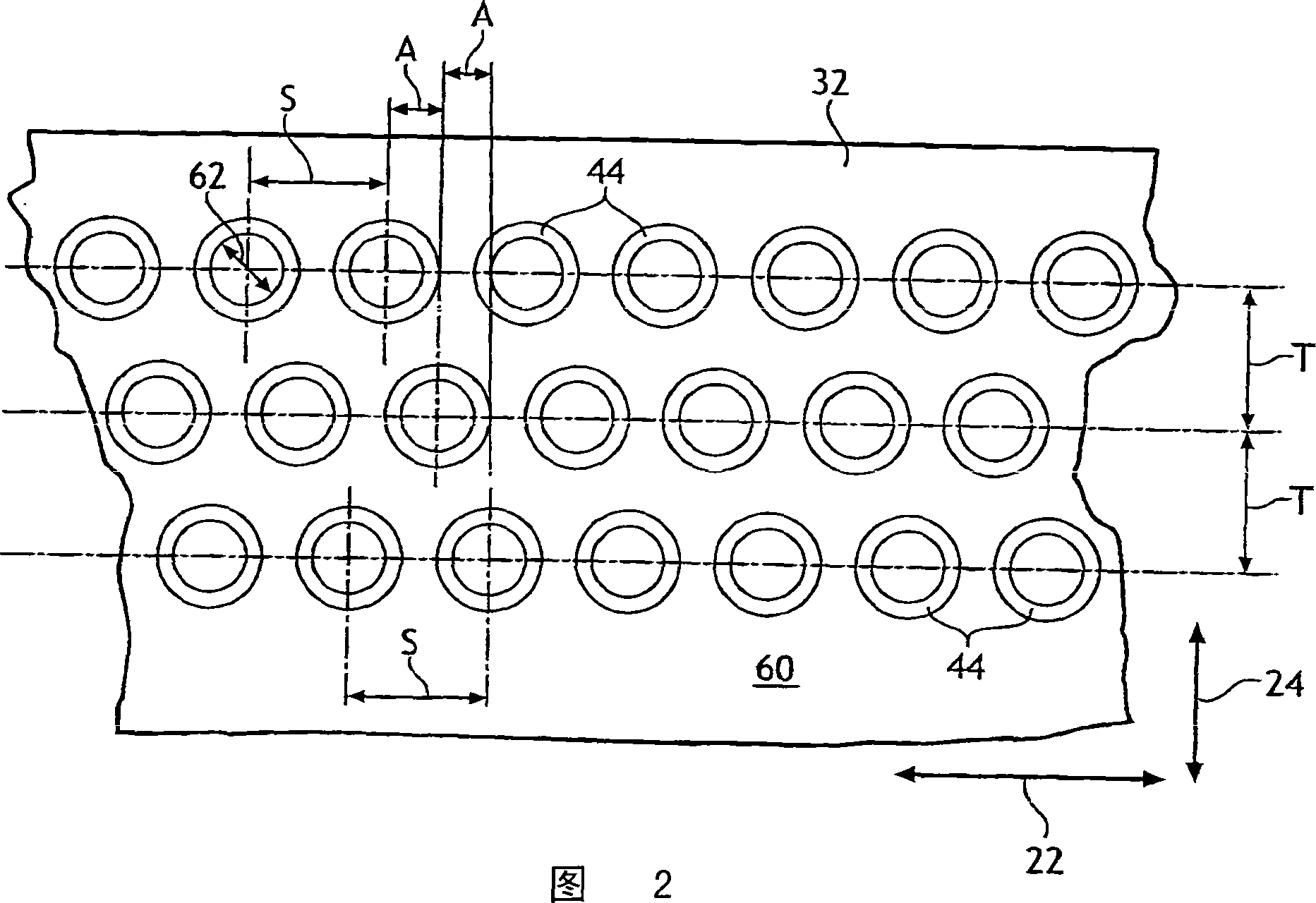

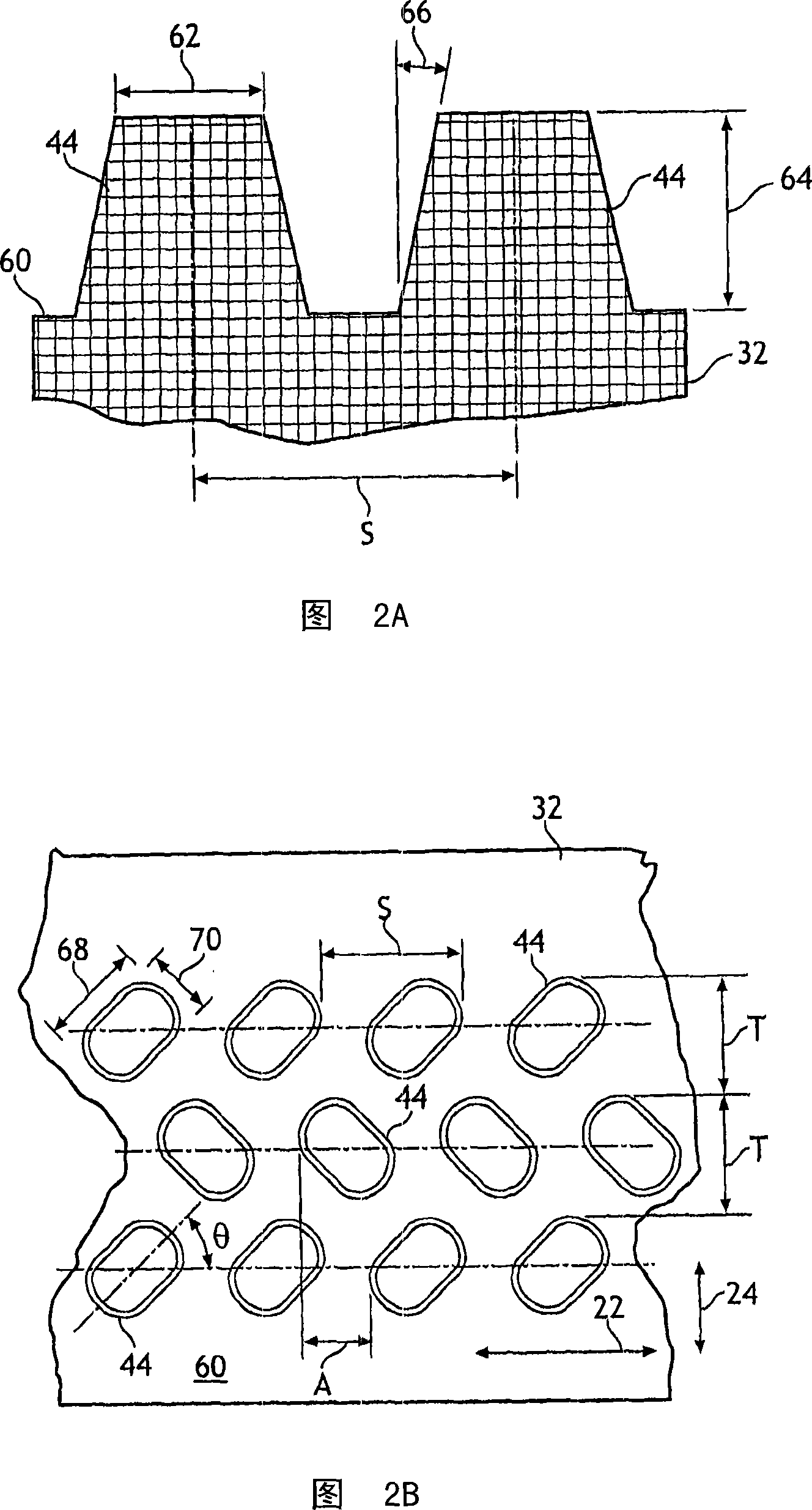

[0196] [131] Additional examples provide data related to the following process variables: bonder temperature, bonding speed, and bonding pressure value in the nip area between bonding rolls. The data also relates to the possible impact of these variables on the bond strength between different combinations of target web materials.

[0197] [132] It is desirable to eliminate the preheat function from the bonding system. Therefore, the effect of bonder temperature on the results of pressure bonding was studied in order to fully understand the basic mechanism of non-glued mechanical bonding. A JOA pressure bonder (CURT G. JOA, inc., Sheboygan Falls, Wiscons in, U.S.A) was used for the rotation pressure bond test. The patterned roller used has the characteristics and parameters described in Table 4 below.

[0198] [133] Table 4 JOA pressure bonder and needle pattern parameters.

[0199] Adhesive

Needle pattern (round needle)

D 1

mm

D 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com