Method for preparing high purity, compact Ti3SiC2 block material

A block material, high-purity technology, applied in the preparation of Ti, C ceramic blocks, Si field, can solve the problems of high preparation temperature, long reaction time, difficult to prepare large-size materials, etc., to achieve high production efficiency and maintenance Convenience, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

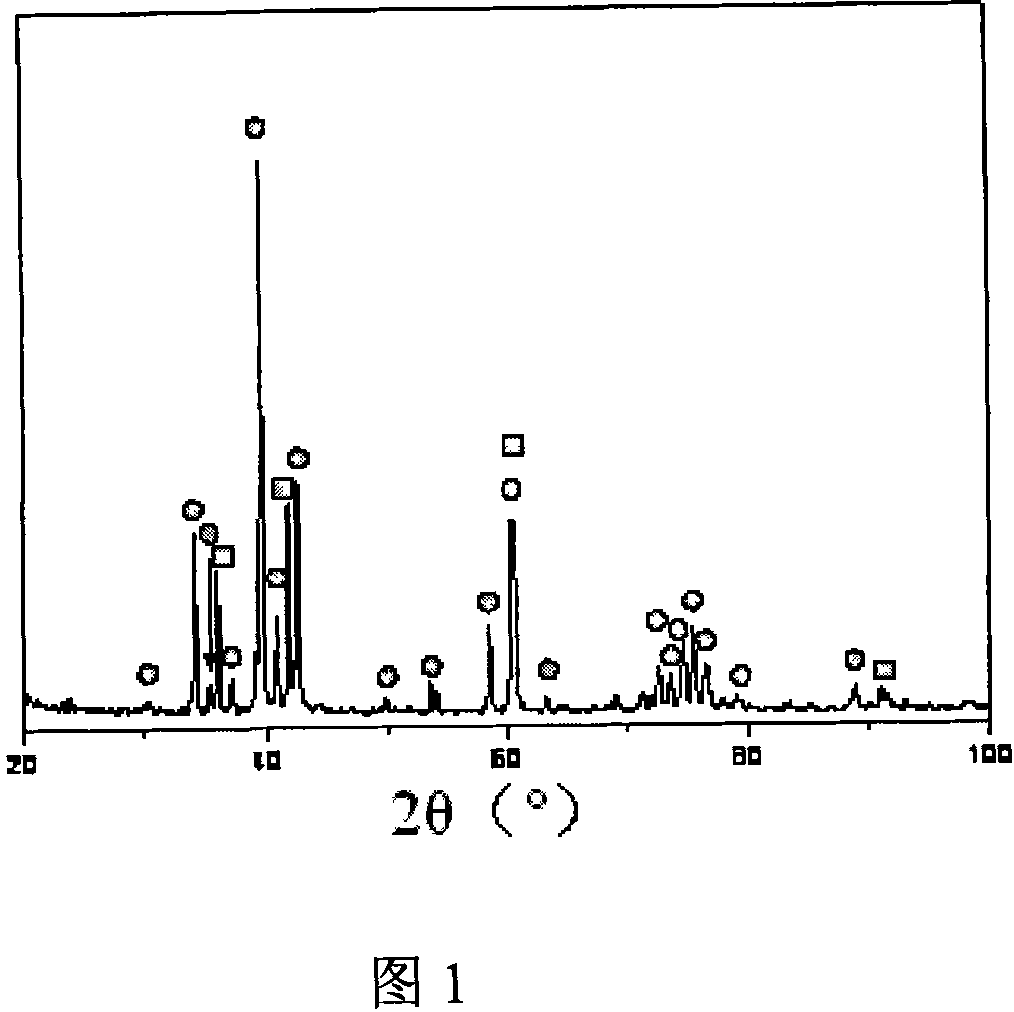

[0013] Specific embodiment one: this embodiment prepares Ti 3 SiC 2 The method for the bulk material is carried out as follows: 1. According to the molar ratio, 2.5 to 3.5 moles of titanium powder, 1-x to 1.5-x moles of silicon powder, x moles of silicon carbide powder and 2-x moles of carbon powder Mix, where 03 SiC 2 blocks.

[0014] In step 1 of this embodiment, absolute ethanol is added as a dispersant to mix the materials evenly, so that the liquid level of the absolute ethanol is submerged by 1-5 mm of the materials.

[0015] The purity of titanium powder, silicon powder, silicon carbide powder and carbon powder in Step 1 of this embodiment is above 98%.

[0016] The Ti produced in this embodiment 3 SiC 2 The block material has a diameter of 30-50mm and a height of 10-20mm.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is: 0.2

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that x=0.25 in Step 1. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com