Harmless treatment method for discarded slurry

A technology of harmless treatment and waste mud, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc. The problem of high operating cost of the reinjection method can achieve the effect of reducing land salinization, reducing pollution and saving land resources.

Inactive Publication Date: 2008-05-28

黄大军

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The solidification method cannot seal the petroleum substances and chlorides in the waste mud and cuttings well, and the reinjection method has high operating costs

Therefore, neither of the above two methods can solve the problem well.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~10

[0068] Preparation of various additives:

[0069] Prepare polydimethyldiallyl ammonium chloride solution 10Kg in a ratio of 0.2%, and the weight ratio added in the waste mud is 10%; prepare polyaluminum chloride aqueous solution 10Kg in a 5% ratio, add in the waste mud The weight ratio is 10%.

[0070] Waste mud and drilling cuttings sampling

[0071] Take waste mud and drilling cuttings 100Kg each time

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

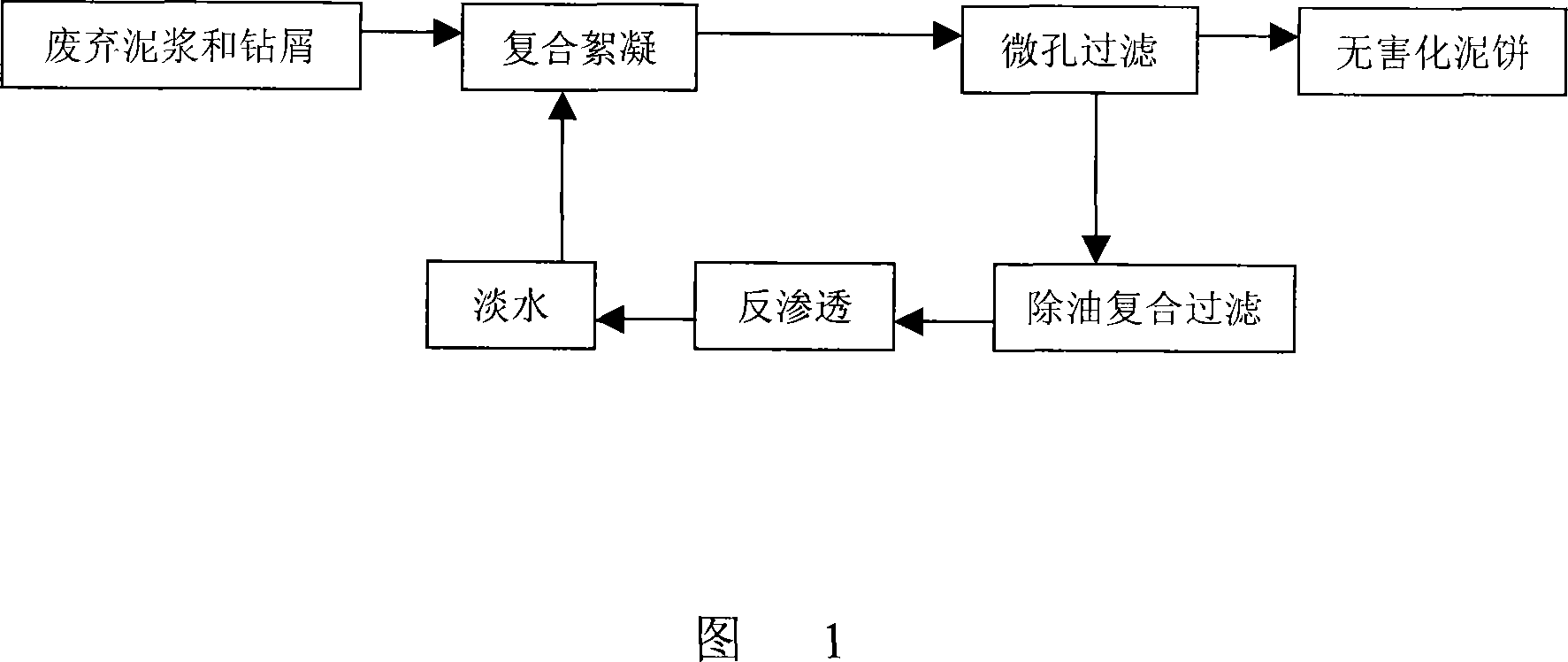

The invention discloses a method of hazard-free treatment of waste slurry, and adopts a physical and chemical method to carry out comprehensive treatment of the waste slurry. Composite effective flocculant is first adopted to carry out flocculation on the slurry to break the colloidal state of the slurry; vacuum absorption is then used for separating water bodies from the slurry and the removal rate of harmful substances in the waste slurry reaches above 99.99 percent; a technique, which combines compound filtering, precision filtering and two-stage reverse osmosis, is used for removing the harmful substances in water. The discharge water after treatment by the method can achieve the grade I of the national Integrated Wastewater Discharge Standard and the oil content and the chloridion content in the discharge water are respectively less more than or equal to 10 mg / l and 250 mg / l, thus saving a lot of land resources and alleviating land salinization caused by bad disposal of the waste and also reducing water pollution.

Description

technical field [0001] The invention relates to the treatment of oil extraction waste, in particular, the invention is a method for harmless treatment of waste mud. Background technique [0002] At present, in the oil industry, drilling is an essential part of oil production. During drilling, the proportion of drilling mud is prepared according to the proportion of formation minerals. Therefore, it is an inevitable process to generate waste mud during drilling. Because some formations contain a large amount of petroleum substances, oily waste mud and drilling oily cuttings will inevitably be produced during the drilling process. Oily waste mud and drilling oily cuttings exist in the mud pool. In addition, when the lubricating oil used for drilling tools is in rainy days, the lubricating oil flows into the mud pool with the rainwater, and the leakage of power generation diesel oil also makes the waste mud contain oil. Generally, the volume of waste mud in a well is 300-400m ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/02C02F1/52C02F1/44

Inventor 黄大军

Owner 黄大军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com