Shape memory composite material and preparation method thereof

A composite material and memory technology, applied in the field of shape memory materials and their preparation, to achieve the effects of excellent structural properties, excellent designability, and improved load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

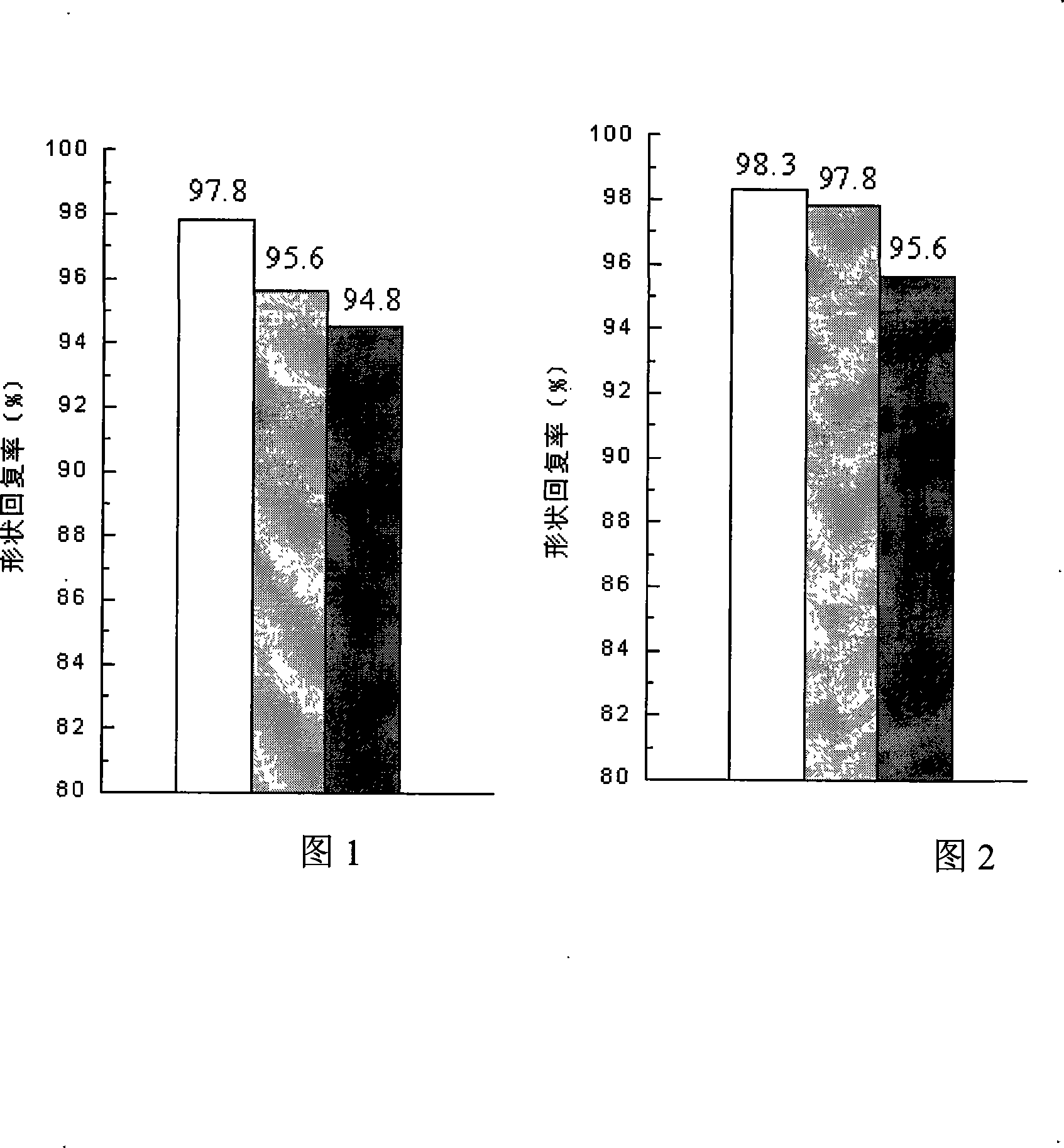

Image

Examples

specific Embodiment approach 1

[0018] Specific Embodiment 1: The shape memory composite material of this embodiment is made of 60-85 parts by mass of thermosetting resin and 15-40 parts of fiber material; Parts of p-diamino-diphenyl-methane and 100 parts of epoxy resin E-51.

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the shape memory composite material also includes 1 to 6 parts of reinforcing agent in terms of parts by mass, and the reinforcing agent is nano-SiO 2 , nano-montmorillonite or polyhedral oligosilsesquioxane. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the fiber material is carbon fiber, aramid fiber or polybenzobisoxazole fiber (PBO fiber). Others are the same as the first embodiment.

[0021] The fibers of the fiber material of this embodiment may be woven fabrics, unidirectional long fibers, or chopped fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com