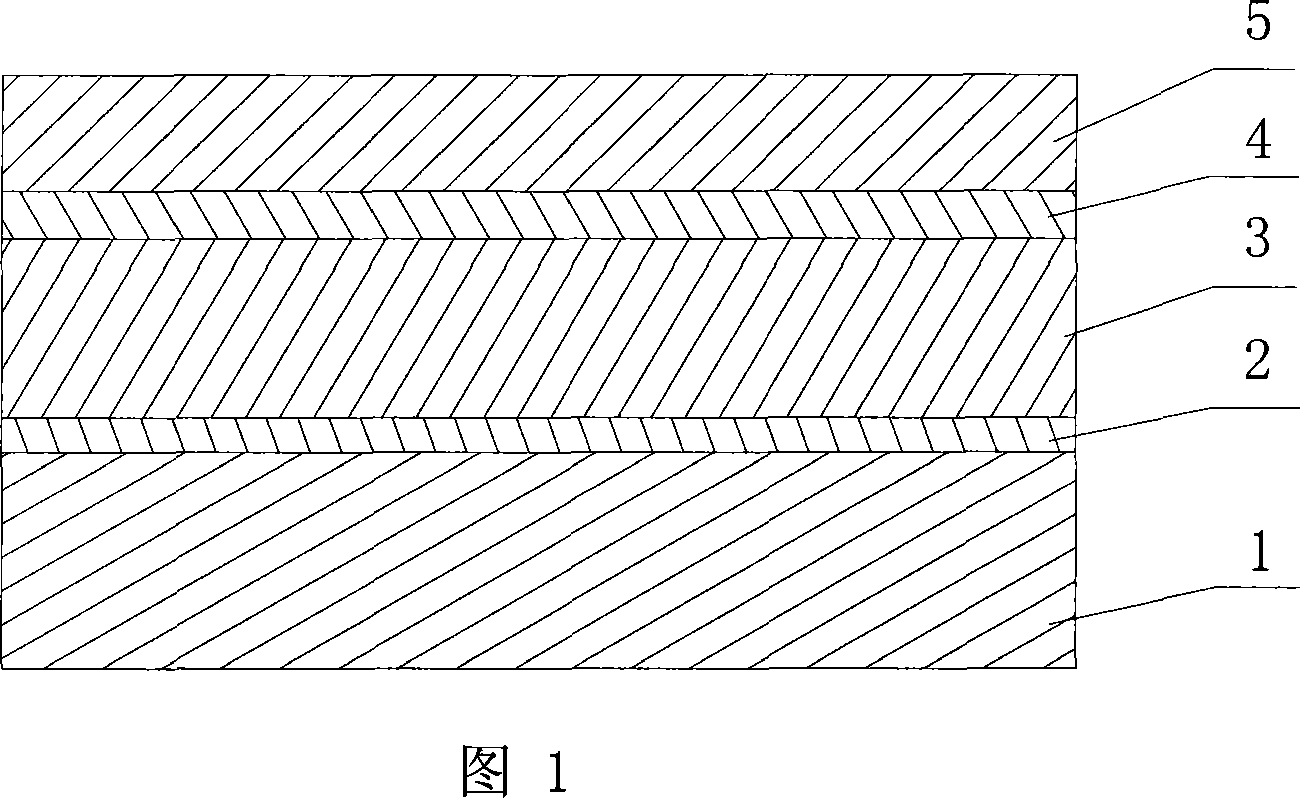

Half-flexible water drainage skid-free noise-reducing road surface pavement structure

A semi-flexible pavement and semi-flexible technology, applied in the field of material science and engineering, can solve problems such as easy cracking of pavement, influence of pavement aesthetics, and impact on driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of materials:

[0043](1) Preparation of drainage anti-slip and noise-reducing wear layer (drainage, anti-skid, noise-reduction wear layer) materials:

[0044] (1) Preparation of high-viscosity modified asphalt: high-viscosity modified asphalt is composed of styrene-butadiene-styrene block copolymer (SBS), activated rubber powder, compatibilizing resin, antioxidant and matrix asphalt; matrix The mass ratio of asphalt, styrene-butadiene-styrene block copolymer, activated rubber powder, compatibilizing resin and antioxidant is 100: 10.6: 3.7: 2.5: 0.3; wherein, the compatibilizing resin is selected rosin glycerin resin, The antioxidant is carbon black, and the base asphalt is AH-70 heavy traffic asphalt; the specific preparation steps are: melt the base asphalt, mix it with styrene-butadiene-styrene block copolymer and compatibilizing resin, and heat it at 170°C Stir under low pressure for 18 minutes, then use a high-speed emulsifying shearer to shear at a...

Embodiment 2

[0089] 1. Preparation of materials:

[0090] (1) The semi-rigid base layer is composed of the following raw materials, and the parts by weight of each raw material are: a) Mineral material: 100 parts; b) Cement: 5 parts; c) Water: 5 parts.

[0091] The mineral material can be limestone or granite, and the mineral material gradation is shown in Table 12.

[0092] (2) Modified emulsified asphalt slurry seal layer material:

[0093] The modified emulsified asphalt slurry seal layer is formed by mixing the following raw materials, and the parts by weight of each raw material are: a) mineral aggregate: 100 parts; b) emulsified asphalt: 15 parts; wherein the mineral aggregate is composed of aggregate and filler, The mass ratio of aggregate to filler is 100:11.1; the aggregate is basalt, the filler is limestone powder, and the emulsified asphalt is SBR modified emulsified asphalt.

[0094] (3) The semi-flexible pavement material structure layer is formed by pouring polymer modified...

Embodiment 3

[0112] 1. Preparation of materials:

[0113] (1) The semi-rigid base layer is composed of the following raw materials, and the parts by weight of each raw material are: a) Mineral material: 100 parts; b) Cement: 5 parts; c) Water: 5 parts.

[0114] The mineral material can be limestone or granite, and the mineral material gradation is shown in Table 12.

[0115] (2) The modified emulsified asphalt slurry seal layer is formed by mixing the following raw materials, and the parts by weight of each raw material are: a) Mineral material: 100 parts; b) Emulsified asphalt: 15 parts; wherein the mineral material is made of aggregate The mass ratio of aggregate to filler is 100:11.1; the aggregate is diabase, the filler is limestone slag, and the emulsified asphalt is SBR modified emulsified asphalt.

[0116] (3) The semi-flexible pavement material structure layer is formed by pouring polymer modified cement-based grouting material on the macroporous asphalt mixture matrix on the modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com