Shuttering member for in situ concrete

A technology of formwork components and cast-in-place concrete, which is applied in the direction of building components, formwork/formwork/work frames, and on-site preparation of building components, which can solve the problems of increasing construction costs and reducing construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

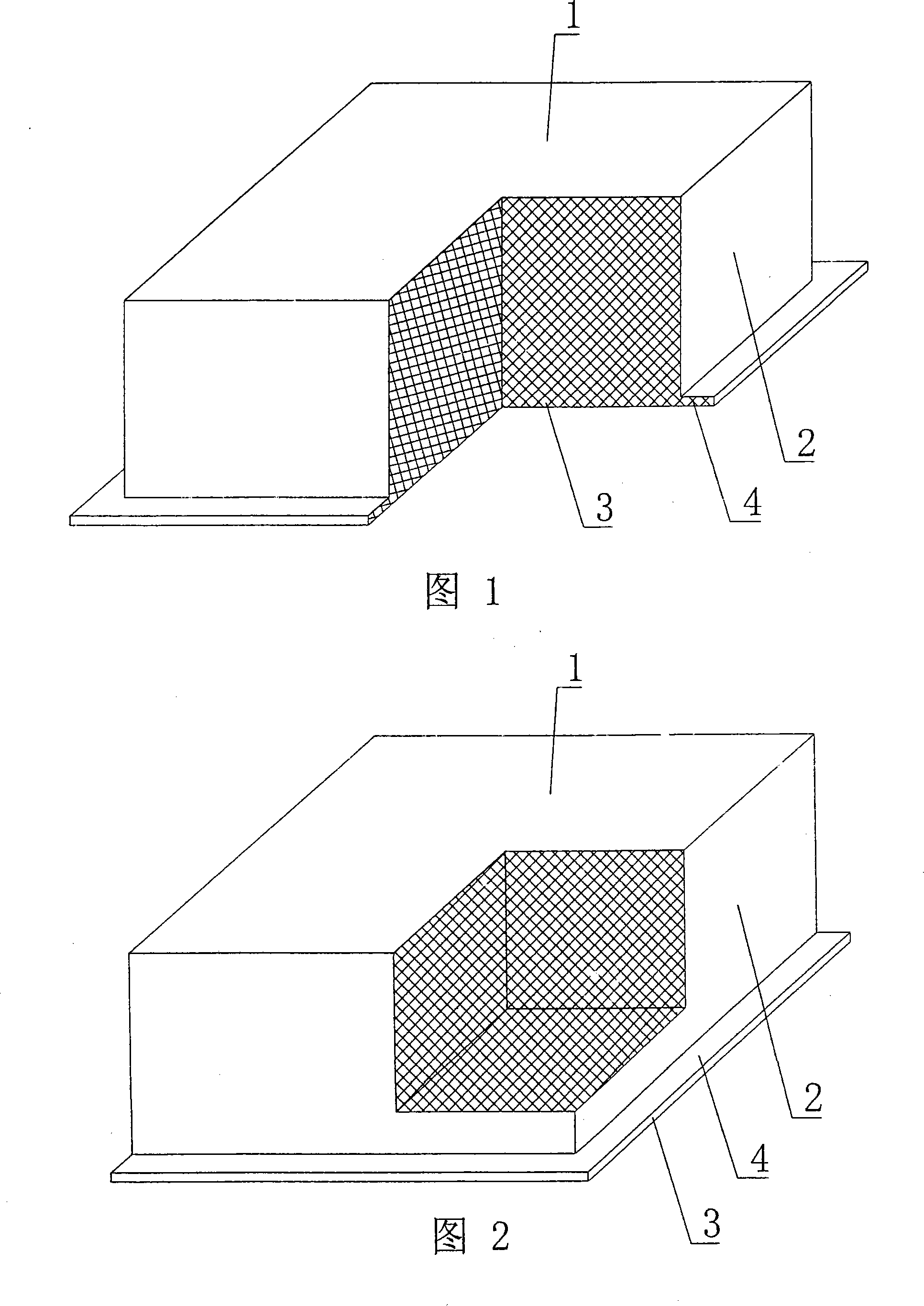

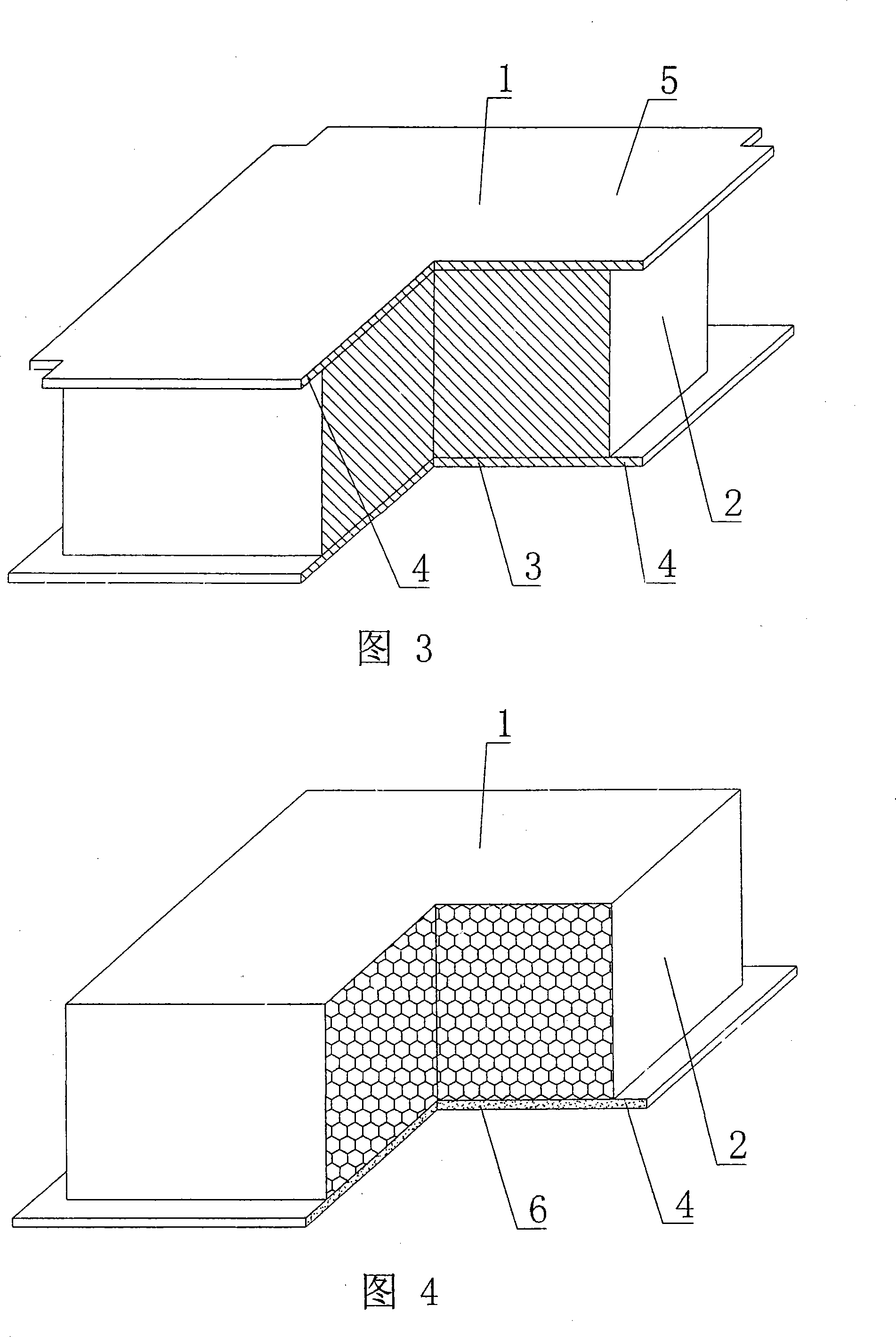

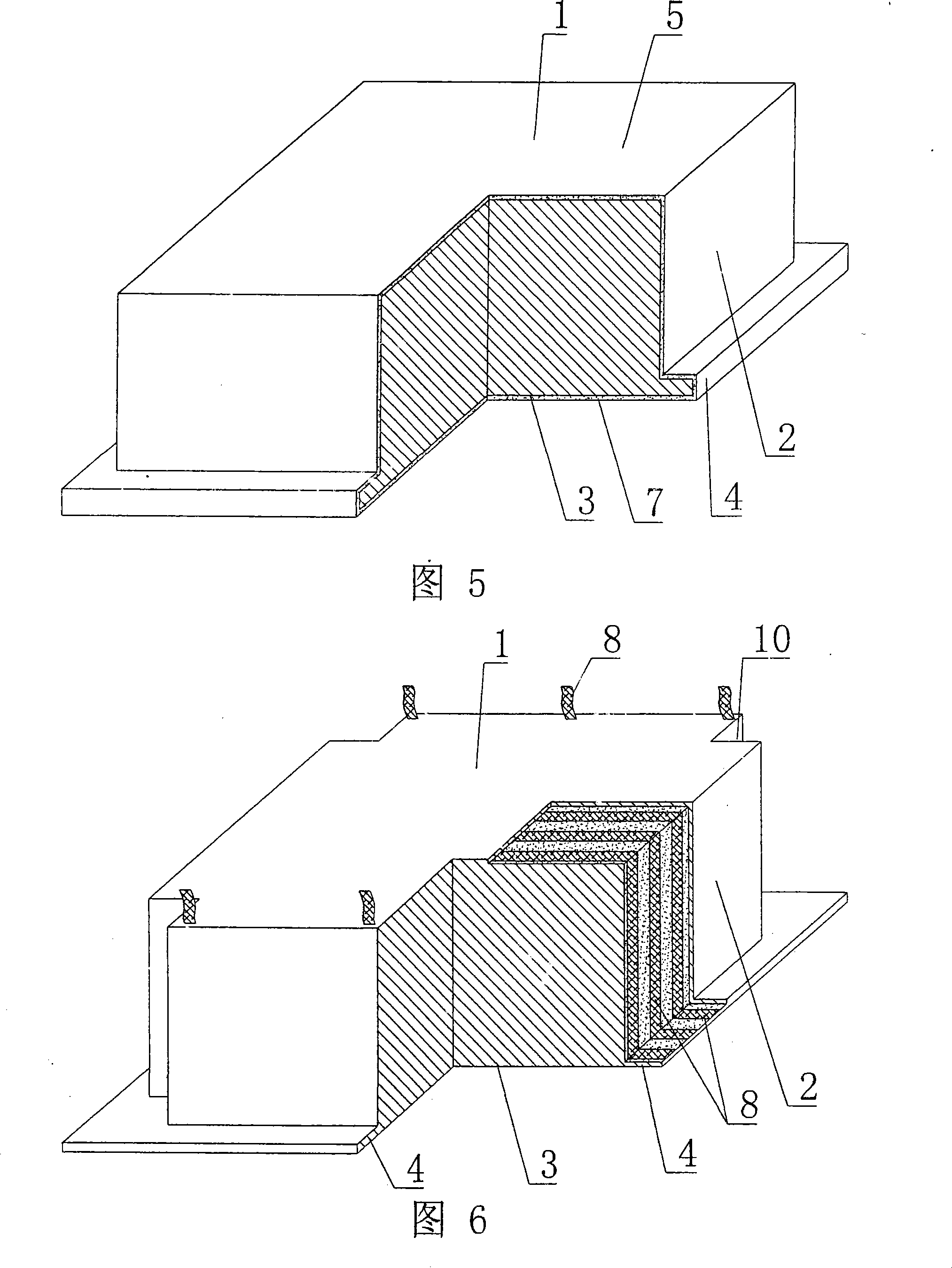

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] As shown in the accompanying drawings, the present invention includes a polyhedral solid lightweight material member 1, which is characterized in that a pick plate 4 is protruded outward along the bottom surface 3 on at least one surrounding side 2 of the polyhedral solid light material member 1, and the pick plate 4 The pick plate formed by setting and connecting the polyhedral solid lightweight material component 1 on the cement mortar or cement concrete bottom plate 6, the polyhedral solid lightweight material component 1 is foamed plastic block, expanded perlite block, expanded vermiculite block, foamed Or aerated concrete block, ceramsite concrete block, straw chaff cementing material block, charcoal concrete block or cement-bonded foam particle block material, the outer surface has an outer film layer 7, and the bottom plate 6 contains a rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com