Evaluation method of rubber-plastic viscoelasticity element fatigue performance

A technology of fatigue performance and components, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the difficulty in selecting stiffness ranges, differences in stiffness, wear and surface cracks, and unknown differences in product performance impacts, etc. problems, to achieve the effect of facilitating quantitative analysis and comparison, shortening test time, and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

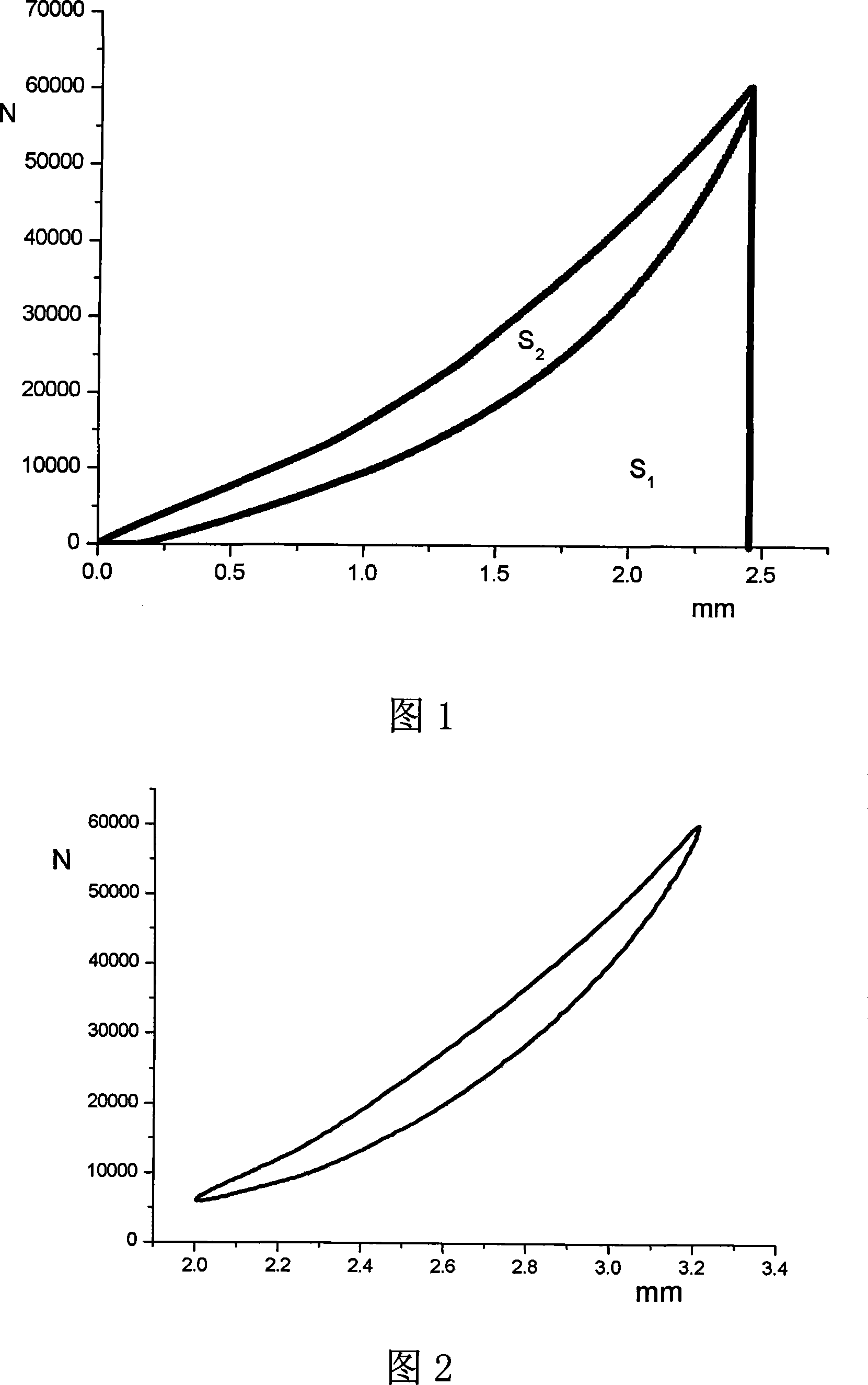

[0061] Taking the development test of a rubber bushing for an air suspension system of a certain vehicle type as an example, the application of the present invention in automobile rubber damping components is described. (The products involved in the following are all materials of the same formula, only the difference in product shape and structure) The rubber bushing is integrally press-fitted into the metal sleeve at the front end of the car's air suspension beam to realize the flexibility of the frame and axle It is connected to play the role of bearing, buffering and noise reduction, with a rated load of 60,000 N

[0062] By adopting the method of the present invention, the fatigue resistance of different products under the same working condition is assessed according to the set test cycle index.

[0063] 1-1. Test method: Under the same test cycle, test the energy loss change rate ΔE of the two samples A and B before and after the fatigue test.

[0064] 1-1.1 Test equipment: M...

Embodiment 2

[0103] 2-1 Test method: According to the set energy loss change rate ΔEx index, test the number of test cycles Nx when the A and B samples reach the fatigue limit, that is, the energy loss change rate ΔEx index under the same working conditions.

[0104] 2-1.1 Test equipment: MTS810 dynamic and static universal testing machine.

[0105] 2-1.2 Test parameters: The test frequency is 3Hz, and the energy loss rate of change of the two samples A and B reaches the fatigue limit ΔEx=±10%.

[0106] 2-1.3 Dynamic load range: radial static load 33000 N, radial dynamic load ± 27000 N

[0107] 2-2 Test procedure:

[0108] Step 2-2.1 is the same as the step 1-2.1 in Example 1.

[0109] 2-2.2 Set test parameters: same as steps 1-2.2 in Example 1.

[0110] 2-2.3 The fatigue test starts after 6000 times of dynamic vibration. After the dynamic fatigue test starts, the test data of the load-displacement closed curve of the first three adjacent cycles is recorded, and the average value of the record...

Embodiment 3

[0130] 3-1. Test method: The radial stiffness curve of sample A in Example 1 was tested by a traditional method (stiffness change rate) to verify the accuracy of the method data of the present invention.

[0131] 3-1.1 Test equipment: MTS810 dynamic and static universal testing machine or material testing machine.

[0132] 3-1.2 Test parameters: Test frequency 3Hz, fatigue test period 1.0×10 7 The test speed is 2mm / min and the static load is 60000N.

[0133] 3-2. Test steps:

[0134] 3-2.1 is the same as the steps of 1-2.1 in Example 1.

[0135] 3-2.2 is the same as the steps of 1-2.2 in Example 1,

[0136] 3-2.3 The fatigue test starts after 6000 times of dynamic vibration. After the dynamic fatigue test starts, test and draw the stiffness curves P1 and P2 of sample A before and after the fatigue test:

[0137] In the test, record the radial displacement of sample A due to load changes, and draw the stiffness curve P1 of sample A before the fatigue test and the stiffness curve P2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com