Magnetism driven telescopic driver

A magnetostrictive and magnetostrictive rod technology, which is used in the field of devices that convert electrical energy into sound energy and magnetostrictive drives, which can solve the problems of poor synchronization of parallel operation of vibration exciters, limited acoustic wave propagation distance, and difficulty in realizing automatic control, etc. problem, to achieve the effect of non-directional sound, improved sensitivity and fidelity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

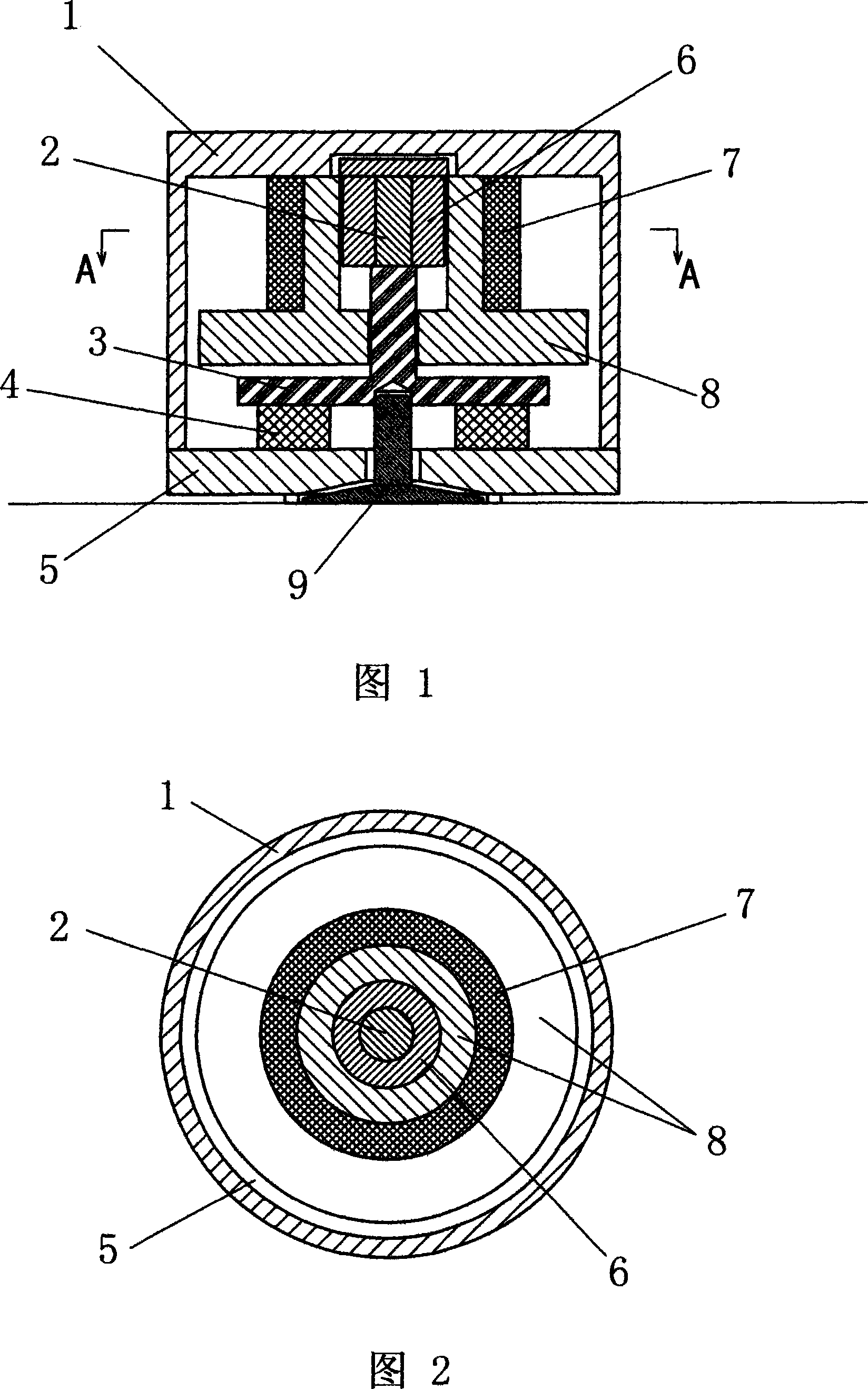

[0019] Referring to Fig. 1 and Fig. 2, it includes a hollow cylindrical shell formed by connecting the upper cover 1 and the base 5, and the shell is made of metal material with good heat dissipation performance. A magnetostrictive rod 2, a fixed support 6, a coil support 8, a drive coil 7, a transmission rod 3 and an output device 9 are respectively arranged along the axis in the housing, and the above-mentioned parts are coaxially arranged. By applying a changing magnetic field, the magnetostrictive rod 2 can expand and contract in the axial direction; the fixed bracket 6 is located on the periphery of the magnetostrictive rod 2 and is made of a magnetically permeable material for providing a bias magnetic field to the magnetostrictive rod 2 Magnetic conduction and positioning; the fixed bracket 6 is cylindrical with one end closed and the other open, and the magnetostrictive rod 2 is a cylinder, which is accommodated in the hollow portion of the cylindrical fixed bracket 6 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com