Heat radiator

A heat sink and heat sink technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problems of heat transfer capacity reduction of heat pipes, capillary structure damage, and affecting the overall heat dissipation performance of heat sinks, etc., to achieve High heat dissipation performance, the effect of overcoming the interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

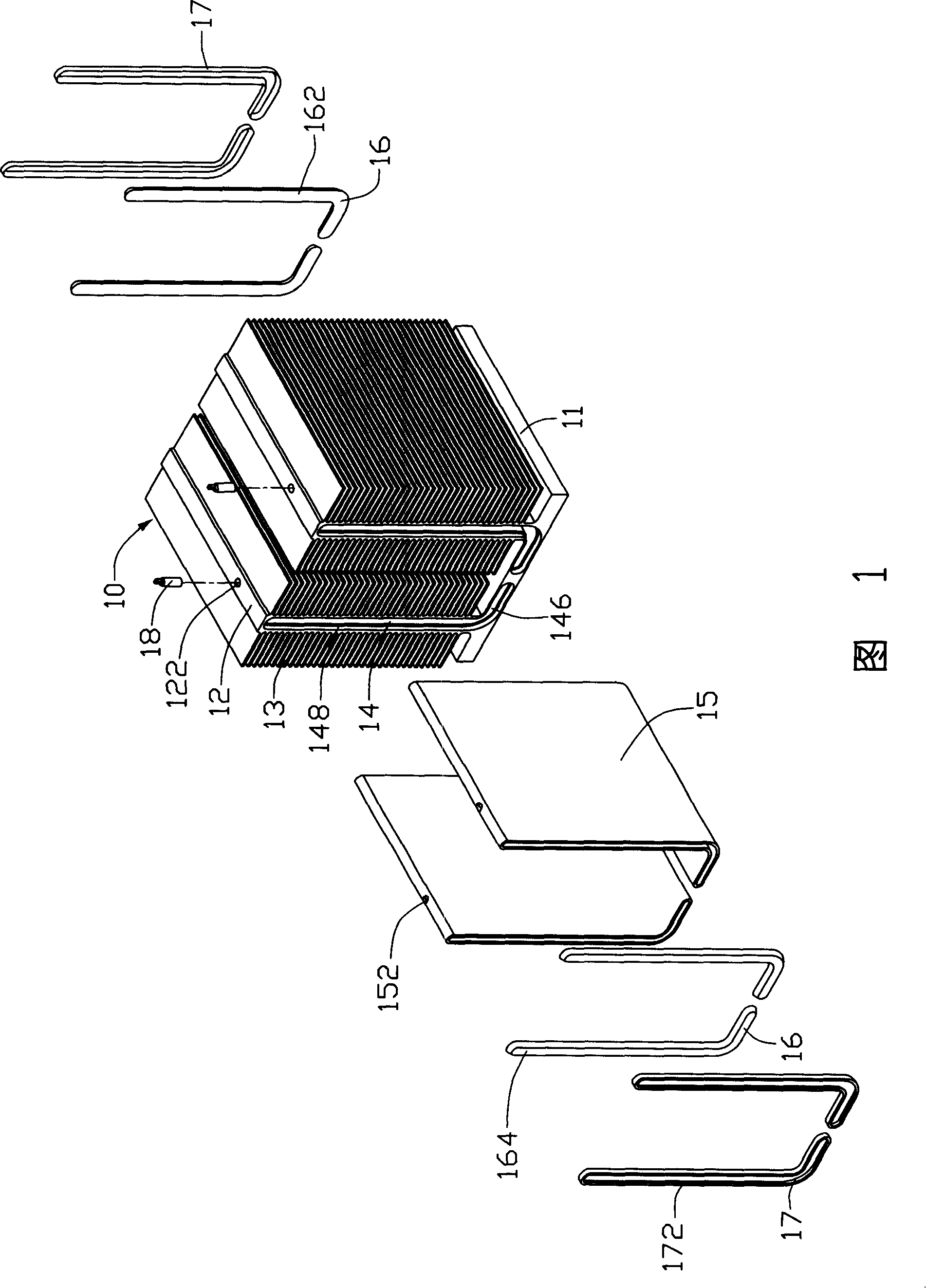

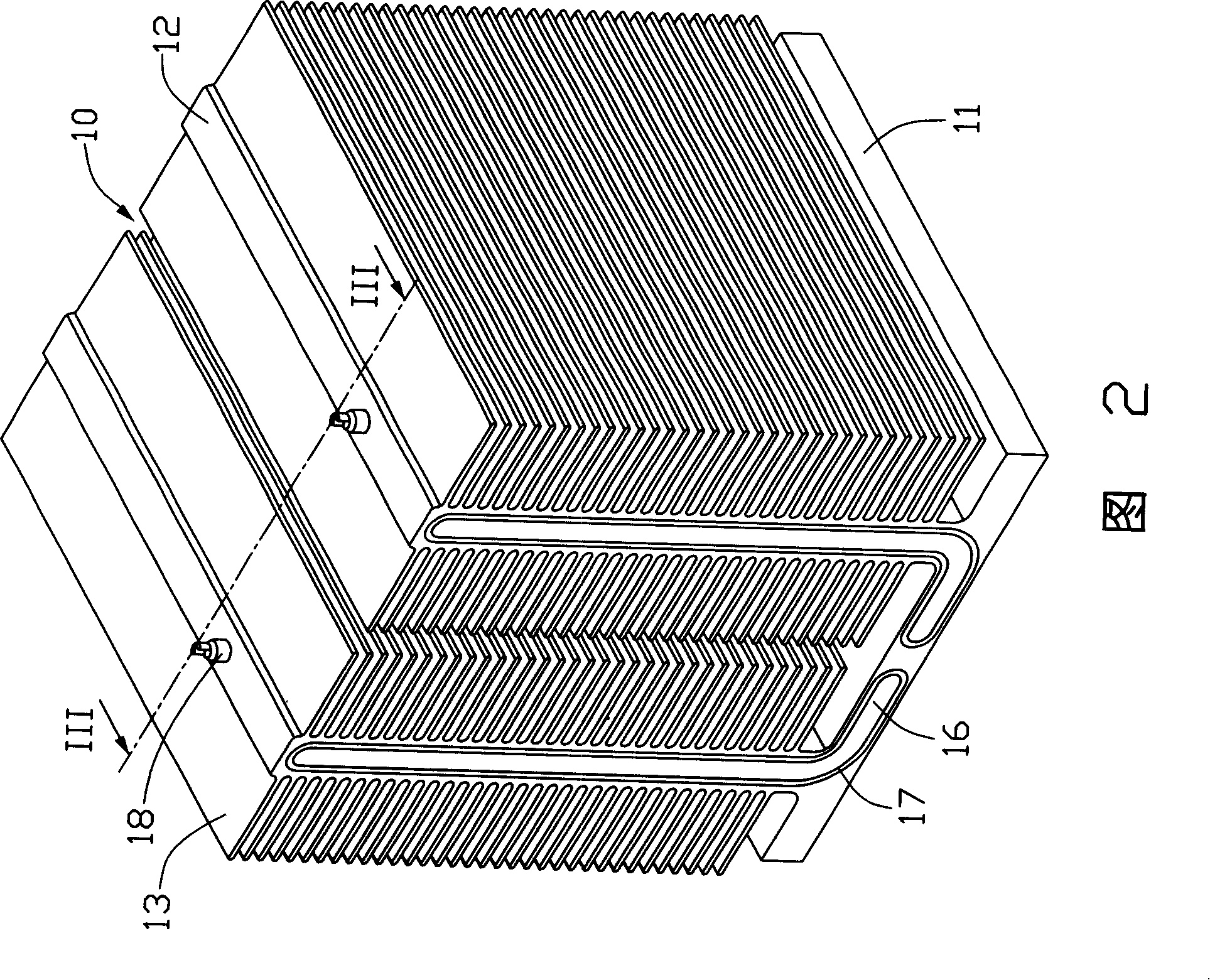

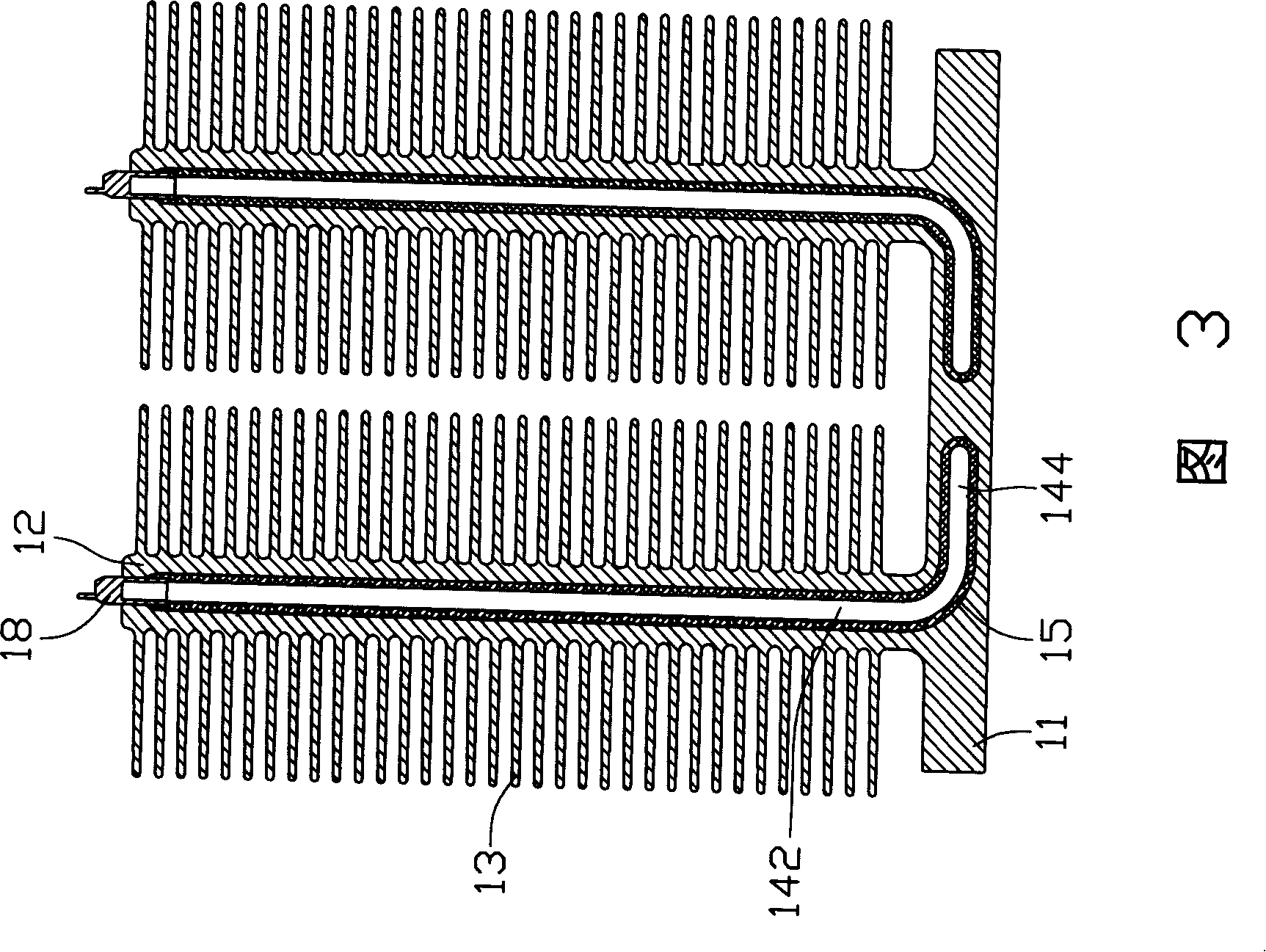

[0012] The heat dissipation device of the present invention will be further described below with reference to the accompanying drawings.

[0013] Please refer to Fig. 1 to Fig. 3, the heat dissipating device of the first embodiment of the present invention comprises the heat sink 10 of extruded aluminum, and this heat sink 10 comprises a rectangular heat conduction base 11, and the bottom surface of this heat conduction base 11 forms a plane (not marked) for The electronic components are bonded, and the middle part of the top surface of the heat conduction base 11 has two heat conduction wings 12 vertically extending upward at a certain distance. The heat conduction wings 12 are plate-shaped with a certain thickness, and a plurality of parallel and spaced cooling fins 13 are vertically extended laterally on two sides thereof. Each heat conduction wing 12 is provided with a channel 14 with a slightly L-shaped cross section in the heat conduction base 11 connected thereto. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com