Phase error detecting apparatus

A technology of phase difference detection and phase error, which is applied in the configuration/installation of the head, instruments, data recording, etc., and can solve problems such as unstable tracking servo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Hereinafter, a phase error detection device according to Embodiment 1 of the present invention will be described.

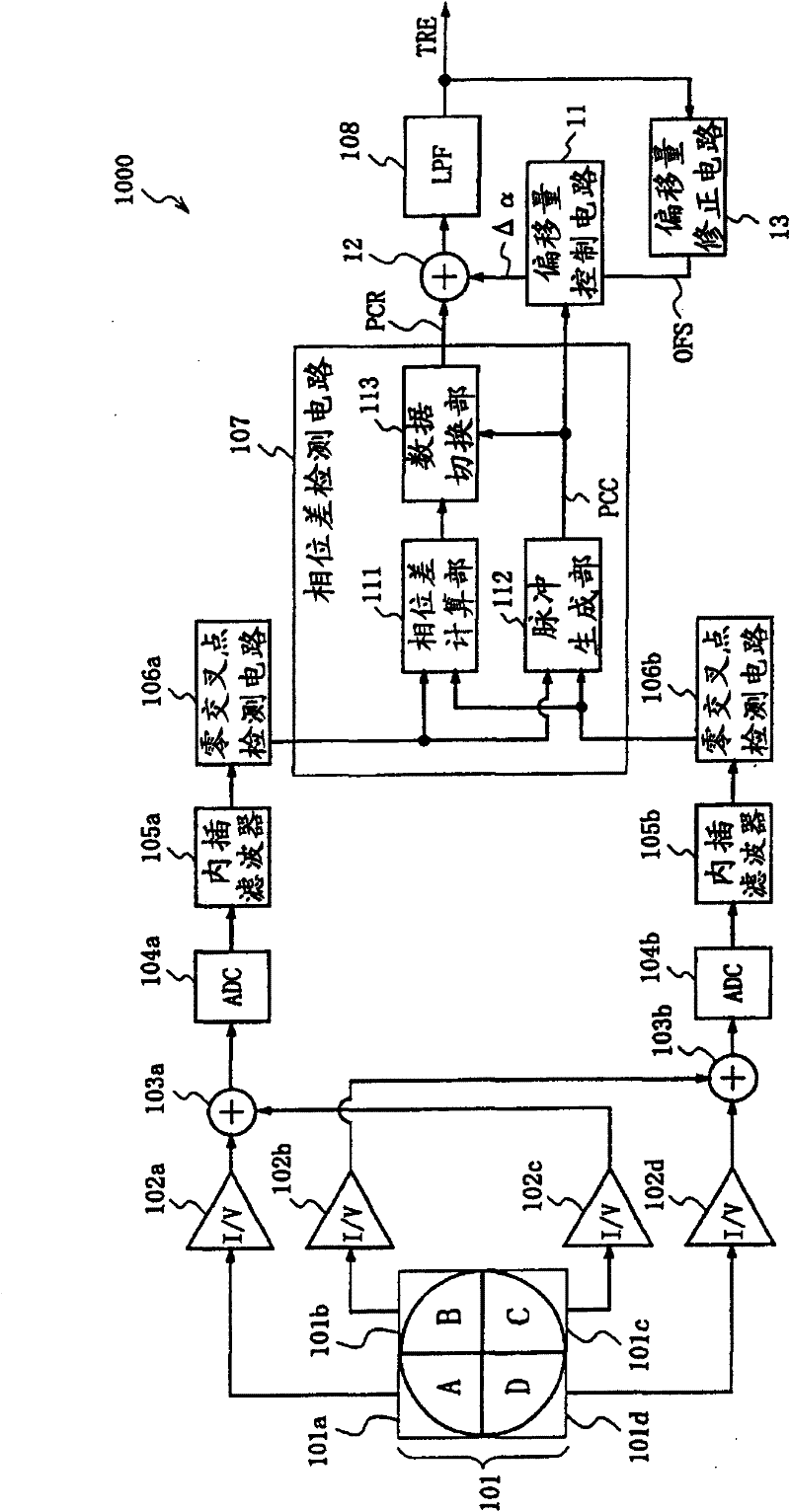

[0126] figure 1 is a block diagram of the configuration of the phase error detection device 1000 according to Embodiment 1 of the present invention.

[0127] exist figure 1 Among them, the phase error detection device 1000 of the present embodiment 1 is configured to include: a photodetector 101 having a photosensitive element that receives reflected light from a light spot, and outputting a photocurrent corresponding to the amount of light received by each photosensitive element; Current-to-voltage converters 102a-102d; signal generators that generate two signal sequences, that is, first and second adders 103a, 103b; first and second analog-to-digital converters (ADC) 104a, 104b; first and second Interpolation filters 105a, 105b; first and second zero-cross point detection circuits 106a, 106b; phase difference detection circuit 107; low-pass filter (L...

Embodiment 2

[0141] Next, a phase error detection device according to Embodiment 2 of the present invention will be described.

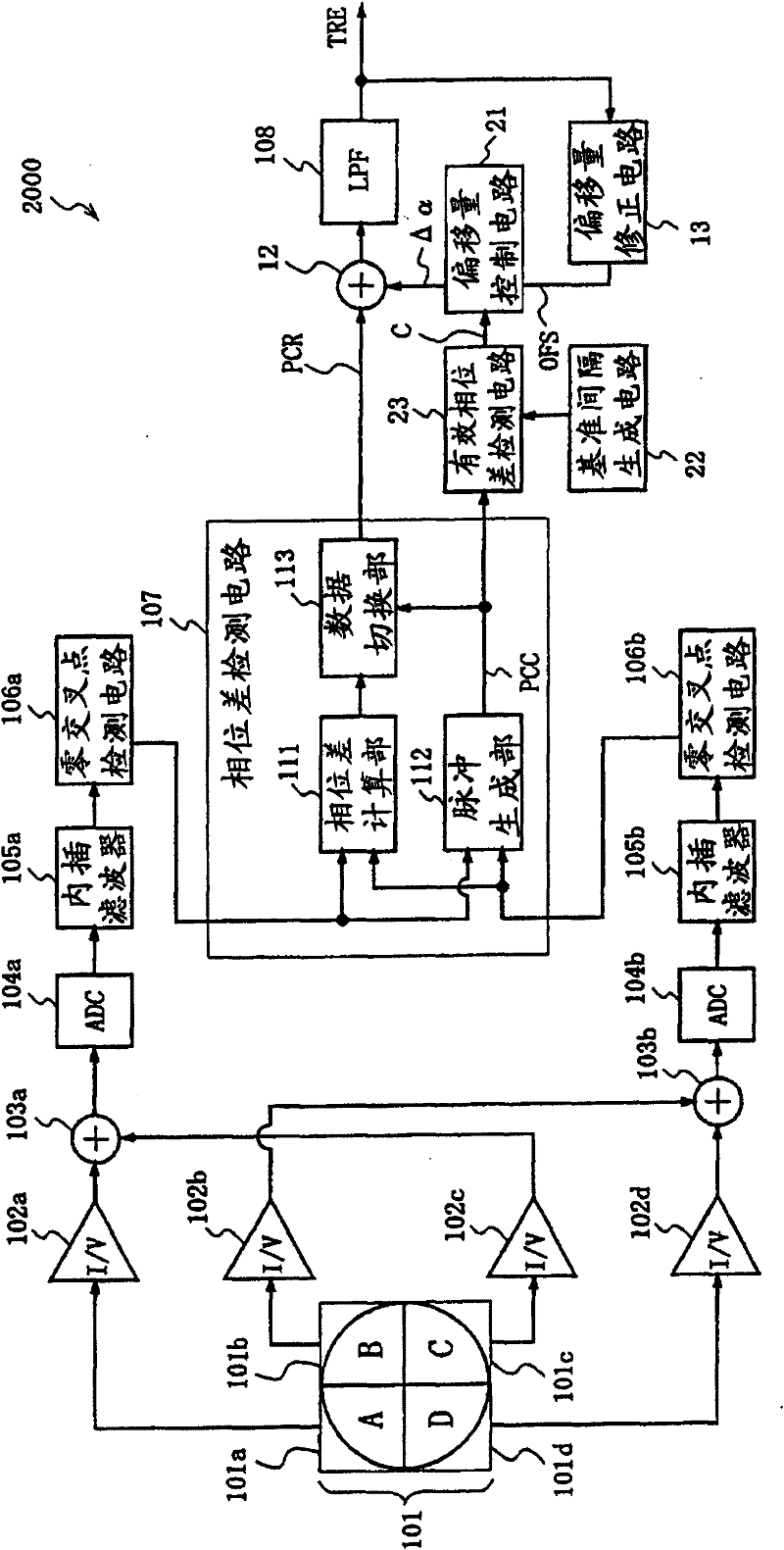

[0142] image 3 It is a structural block diagram of a phase error detection device 2000 according to Embodiment 2 of the present invention.

[0143] exist image 3 Among them, the phase error detection device 2000 of the present embodiment 2 is configured to include: a photodetector 101 having a photosensitive element that receives reflected light from a light spot, and outputting a photocurrent corresponding to the amount of light received by each photosensitive element; Current-to-voltage converters 102a-102d; signal generators that generate two signal sequences, that is, first and second adders 103a, 103b; first and second analog-to-digital converters (ADC) 104a, 104b; first and second Interpolation filters 105a, 105b; first and second zero-cross point detection circuits 106a, 106b; phase difference detection circuit 107; low-pass filter (LPF) 108; third add...

Embodiment 3

[0157] Next, a phase error detection device according to Embodiment 3 of the present invention will be described.

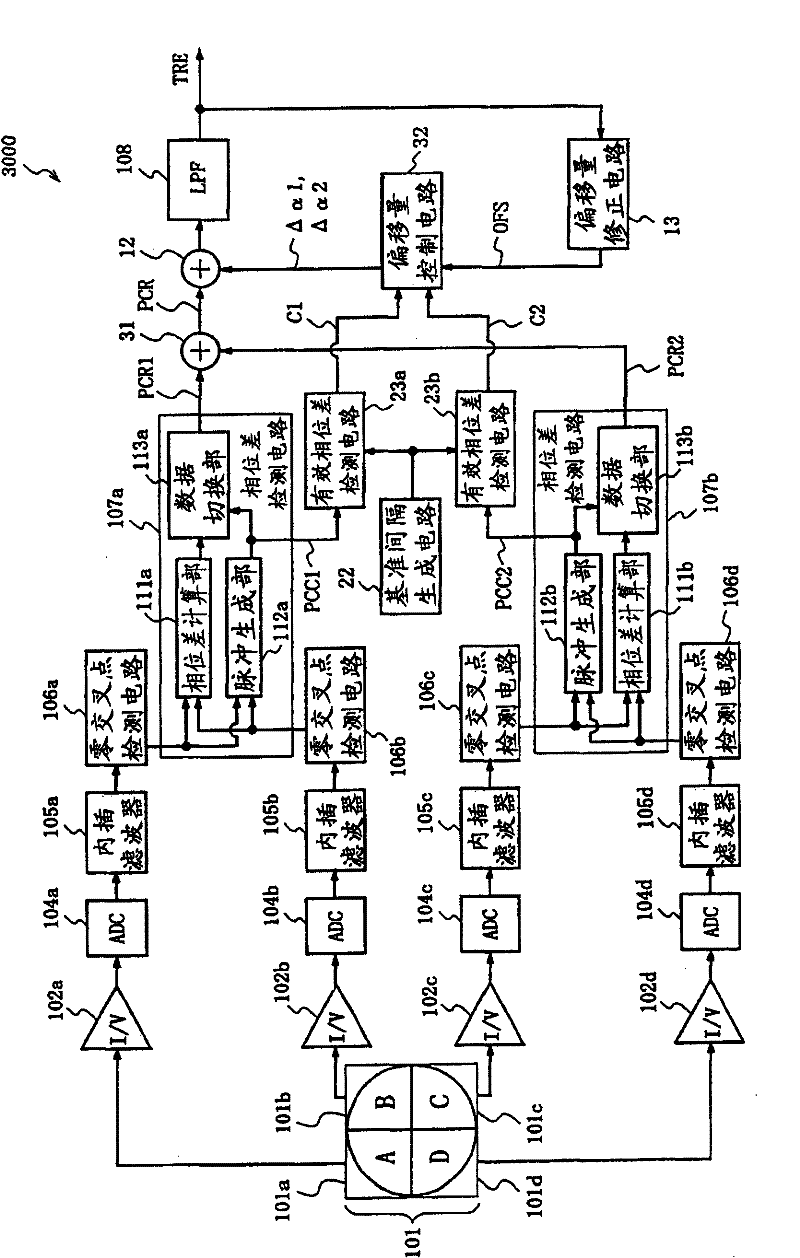

[0158] Figure 5 It is a block diagram showing the configuration of a phase error detection device 3000 according to Embodiment 3 of the present invention.

[0159] exist Figure 5Among them, the phase error detection device 3000 of the present embodiment 3 is configured to include: a photosensitive element having a light receiving reflected light of a light point, and a photodetector 101 outputting a photocurrent corresponding to the amount of light received by each photosensitive element; the photodetector 101 The first to fourth current-to-voltage converters 102a-102d that convert the photocurrent output into voltage signals; obtain the first to fourth digital signal sequences from the voltage signals obtained by the first to fourth current-to-voltage converters 102a-102d First to fourth analog-to-digital converters (ADC) 104a to 104d; first to fourth interp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com