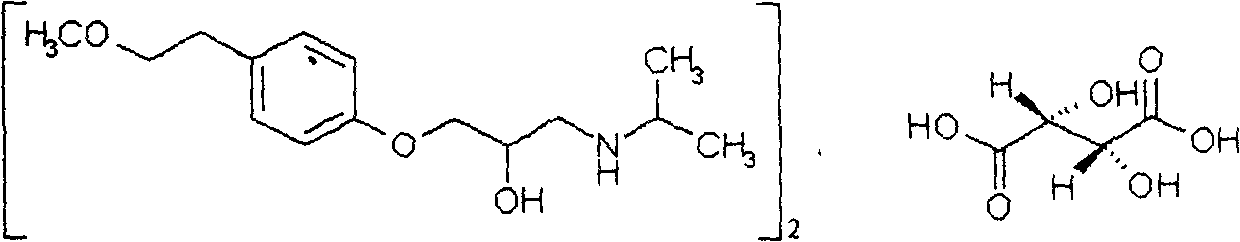

Metoprolol sustained release medicinal compositions and preparation method thereof

A slow-release composition and slow-release coating technology, which can be used in drug combinations, pharmaceutical formulations, drug delivery and other directions, and can solve problems such as changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Different size micropills are coated with medicine and compare

[0038] Weigh 4g of HPMC (6cps), add water to soak overnight, and dissolve. Then add 200g of metoprolol tartrate raw material respectively, then add water, stir and dissolve in a heated state, and obtain the drug-containing coating solution.

[0039] Weigh and weigh 300g of 300μm~400μm, 400μm~500μm, 500μm~610μm, 610μm~750μm sucrose pellets respectively, and place them in the spray coating pan at the bottom of the fluidized bed. Keep at 45±2℃); air inlet pressure is 0.35bar; atomization pressure is 1.5bar; liquid spray rate is 3~5g / min (adjust at any time according to the fluidization state). When the sucrose core was in a fluidized state, the drug-containing coating solution was sprayed on the surface of the blank core by bottom spraying. After the application of the drug, the material continued to be fluidized at 45°C for 5 minutes to obtain the HPMC at different dosage levels. The drug-loaded...

Embodiment 2

[0042] Comparison of different binders in embodiment 2 active drug coating solution

[0043] Weigh 4g each of HPMC (6cps), PVP, and HPC, add water to soak, and dissolve. Then add 200g of metoprolol tartrate raw material, add water 200mL, heat and stir, dissolve, and obtain the coating solution containing medicine.

[0044] Weigh 300g of sucrose ball cores (26-35 mesh), place them in a fluidized bed bottom spray coating pan, set the inlet air temperature at 60°C (keep the temperature in the pot at 45±2°C); the inlet air pressure at 0.35 bar; the atomization pressure is 1.5bar; the spray rate is 3-5g / min (adjust at any time according to the fluidization state). When the sucrose core was in a fluidized state, the drug-containing coating solution was sprayed on the surface of the blank core by bottom spraying. After the application of the drug, the material continued to be fluidized at 45°C for 5 minutes to obtain the HPMC at different dosage levels. Drug-loaded pellets, weighed...

Embodiment 3

[0047] Embodiment 3 pellet active drug coating

[0048] Weigh 4g each of 6cps, 20cps, and 50cps HPMC, add water to soak, and dissolve. Then add 200g of metoprolol tartrate raw material, add water 200mL, heat and stir, dissolve, and obtain the coating solution containing medicine.

[0049] Weigh 300g of sucrose ball cores (26-35 mesh), place them in a fluidized bed bottom spray coating pan, set the inlet air temperature at 60°C (keep the temperature in the pot at 45±2°C); the inlet air pressure at 0.35 bar; the atomization pressure is 1.5bar; the spray rate is 3-5g / min (adjust at any time according to the fluidization state). When the sucrose core was in a fluidized state, the drug-containing coating solution was sprayed on the surface of the blank core by bottom spraying. After the application of the drug, the material continued to be fluidized at 45°C for 5 minutes to obtain the HPMC at different dosage levels. Drug-loaded pellets, weighed.

[0050] Table 3 The results of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com