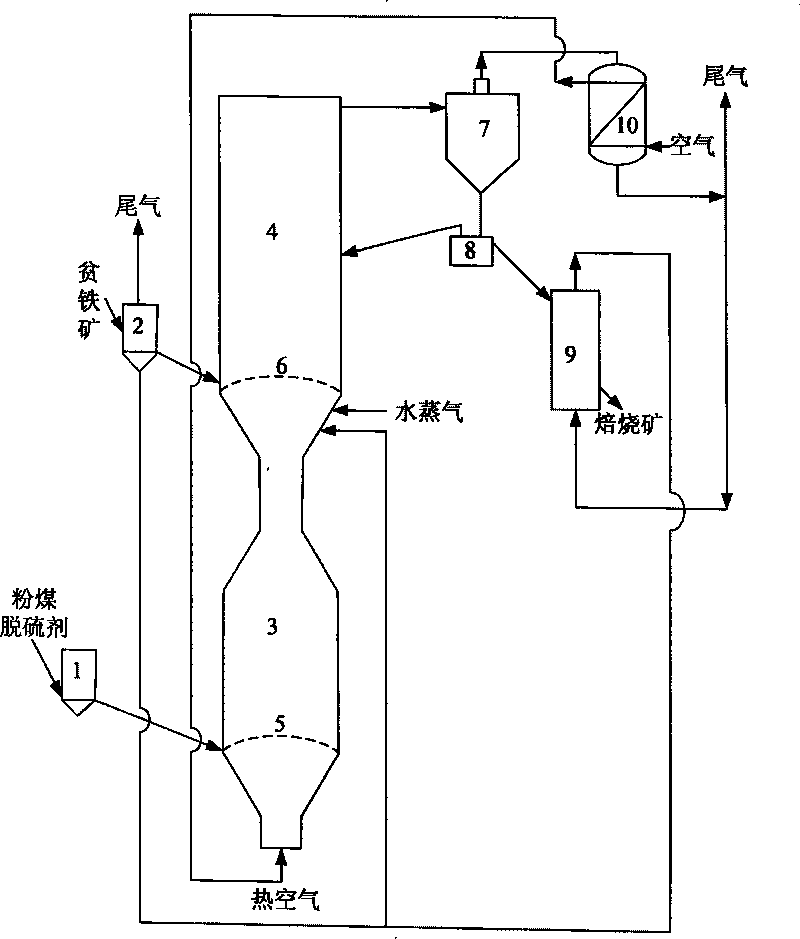

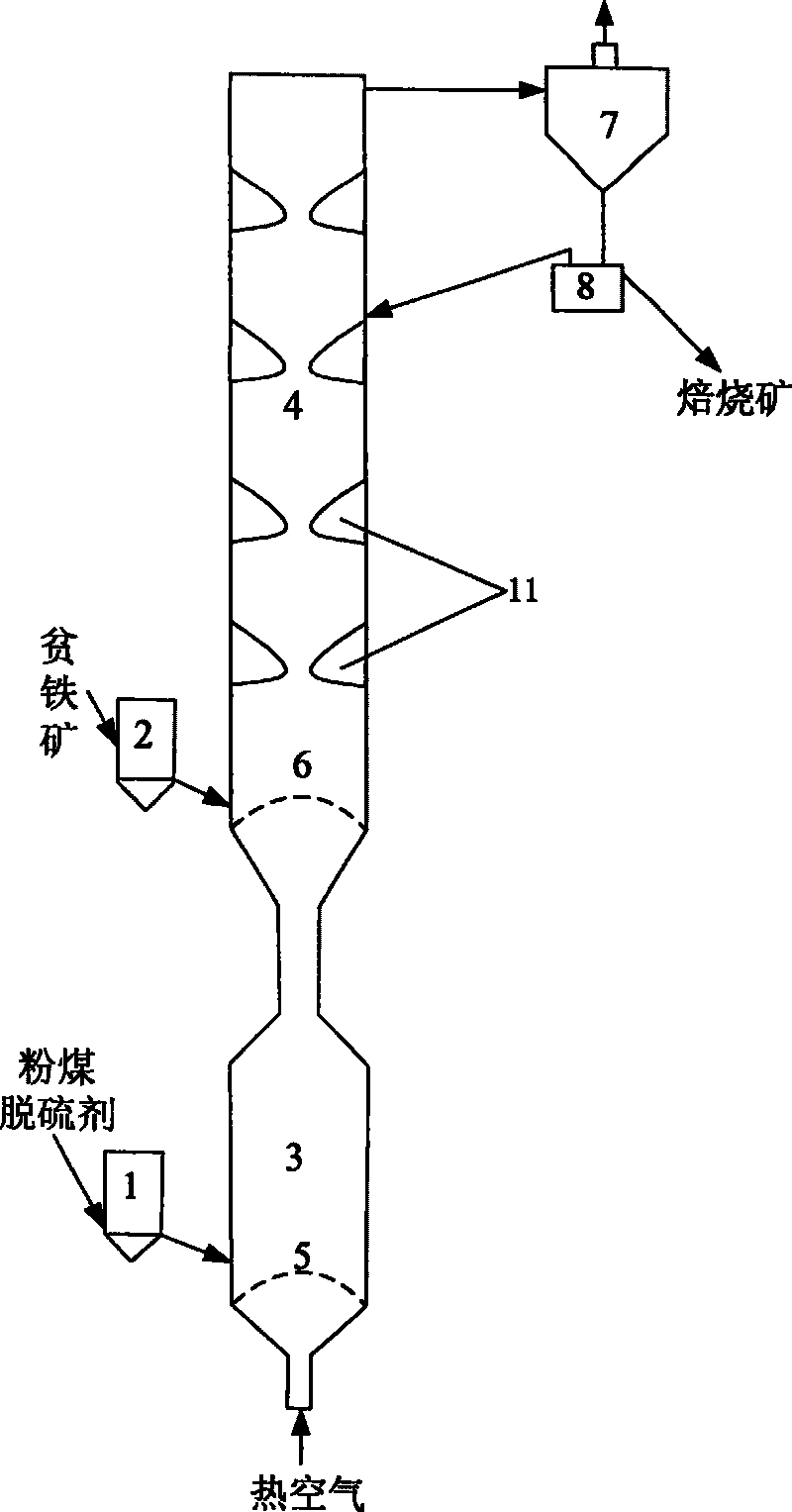

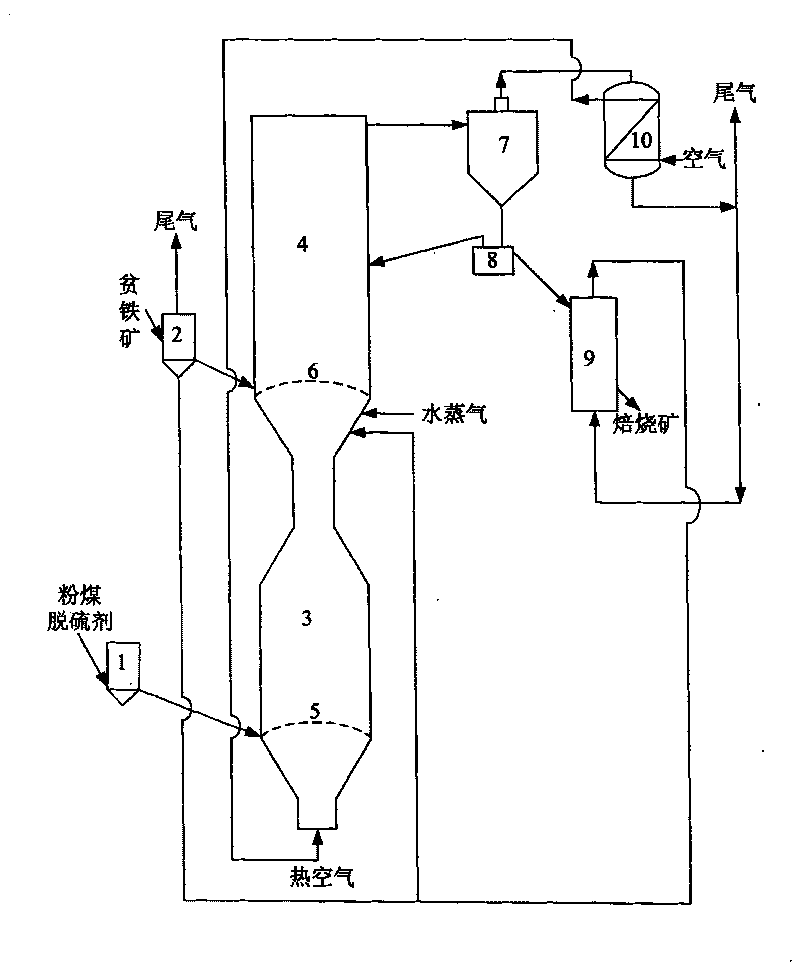

Coal gasification-pore iron ore magnetic roasting coupling technique and device

A technology of coal gasification and magnetization roasting, applied in the fields of metallurgy and chemical industry, can solve problems such as S pollution, and achieve the effect of avoiding pollution, avoiding insufficient reduction, and avoiding some excessive reduction problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: select Henan Lingbao iron ore, raw ore iron grade 46%, iron ore is ground to 80% less than 71 μ m (200 orders); Select Shanxi lignite for use, sulfur content 1wt%, iron ore powder and coal ratio are 15:1; choose CaO as the desulfurizer, the CaO:coal ratio is 1:40, and the coal gasification temperature is 1000°C. The reduction temperature of the iron ore is controlled at 850°C, and the average residence time of the reaction is controlled at 1 minute. The iron ore obtained by roasting is magnetically separated under a 0.9T magnetic field, and the iron concentrate grade can be 60-65%, the yield is 50-58%, the recovery rate is 85-88%, and the iron grade of the tailings is 8-13%. good indicator.

Embodiment 2

[0034] Embodiment 2: select Jiuquan iron ore, raw ore grade iron 38.8%, iron ore is ground to 80% less than 71 μ m; select Shanxi lignite, sulfur content 1wt%, iron ore powder and coal ratio are 10: 1, select CaO As a desulfurizer, the CaO:coal ratio is 1:40, and the coal gasification temperature is 900°C. The iron ore reduction temperature is controlled at 550°C, and the average residence time of the reaction is controlled at 25 minutes. The iron ore obtained by roasting is magnetically separated under a 0.9T magnetic field, and the grade of iron concentrate can be 62%, the recovery rate is 93%, the metal recovery rate is 86%, and the iron grade of tailings is 7.5%.

Embodiment 3

[0035] Embodiment 3: select Anshan hematite, raw ore grade iron 22%, iron ore is ground to 80% less than 71 μ m; select Shanxi lignite, sulfur content 1wt%, iron ore powder and coal ratio are 10: 1, select CaO As a desulfurizer, the CaO:coal ratio is 1:40, and the coal gasification temperature is 900°C. The iron ore reduction temperature is controlled at 700°C, and the average residence time of the reaction is controlled at 10 minutes. The iron ore obtained by roasting is magnetically separated under a 0.9T magnetic field, and the grade of the iron concentrate is greater than 60%, and the iron recovery rate is more than 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com