Raw material suspension preheating magnetizing roasting system and process

A suspension preheating and magnetization roasting technology, which is applied in the field of metallurgy and mineral engineering, can solve the problems of unsatisfactory large-scale industrial production, unsatisfactory ore magnetization effect, and incomplete magnetization degree, so as to improve reduction efficiency, save energy and reduce emissions Significant, low-cost production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

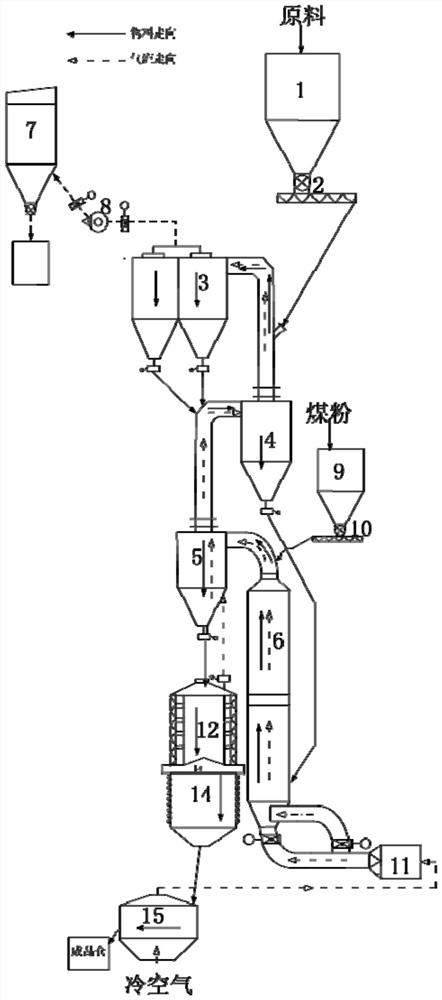

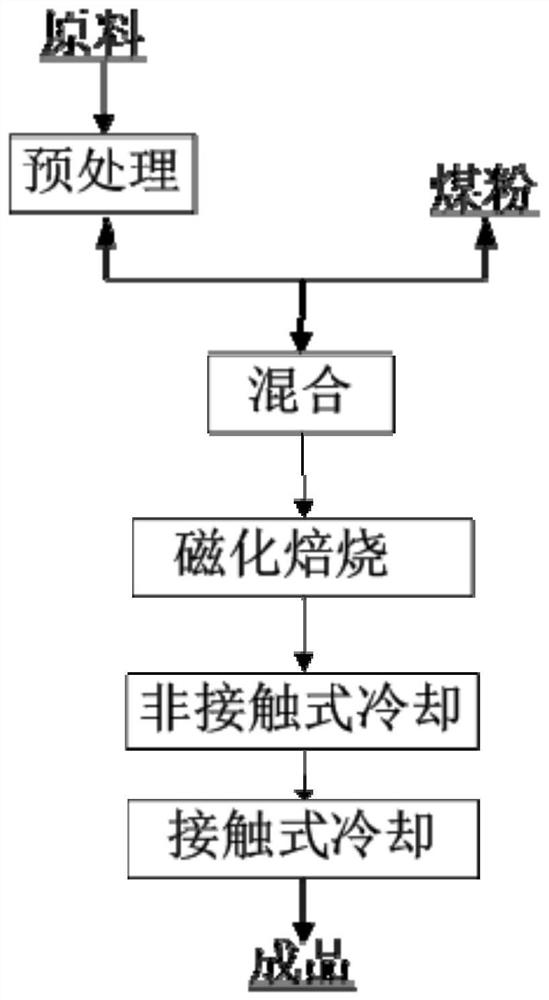

[0040] A raw material suspension preheating magnetization roasting system, such as figure 1 , figure 2As shown, it includes a reducing material silo 1, a reducing agent silo 9, a multi-stage suspension preheating unit, a magnetization roasting holding furnace 12, and a cooling unit. The outlets of the reducing material silo 1 and the reducing agent silo 9 are respectively connected A multi-stage suspension preheating unit, so that the raw materials are pretreated in the multi-stage suspension preheating unit and then mixed with the reducing agent; the multi-stage suspension preheating unit is connected to the feed port of the magnetization roasting and holding furnace 12, and the magnetization roasting and holding The outlet of the furnace 12 is connected with the cooling unit.

[0041] The multi-stage suspension preheating unit is composed of 3 to 5 stages of suspension preheaters, and the number of suspension preheater stages can be appropriately increased or decreased acc...

Embodiment 2

[0063] A hematite in Liaoning has a total iron content of 39.78%, of which the magnetic iron content is only 0.42%. The raw material suspension preheating magnetization roasting system in Example 1 is used to carry out magnetization roasting, the hematite is made to -200 mesh 85%, preheated to 700 ° C by the raw material suspension preheating magnetization roasting system in Example 1, and 5% coal powder is fed into the magnetized roasting and holding furnace 12 together, and the roasting time is 30 minutes; the cooling unit is cooled by water, and the flow rate of the cooling water is 2m / s, and the material is cooled to below 200°C and discharged. The final magnetic susceptibility reached 96%.

Embodiment 3

[0065] The Fe2O3 content of a high-iron bauxite in Yunnan is 22.36%. Using the raw material suspension preheating magnetization roasting system in Example 1 to carry out magnetization roasting, the bauxite is made to -200 mesh 90%, preheated to 900 ° C by the raw material suspension preheating magnetization roasting system in Example 1, and 10% coal powder is fed into the magnetized roasting and holding furnace 12 together, and the roasting time is 60 minutes; the cooling unit is cooled by water, and the flow rate of the cooling water is 2m / s, and the material is cooled to below 200°C and discharged. The final magnetic susceptibility reached 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic susceptibility | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com