Device for extracting high pure aluminum

An extraction device and high-purity technology, applied in the field of foundry metallurgy, can solve the problems of high production cost, high energy consumption, and difficulty in producing high-purity aluminum, and achieve the effect of shortening the purification time and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

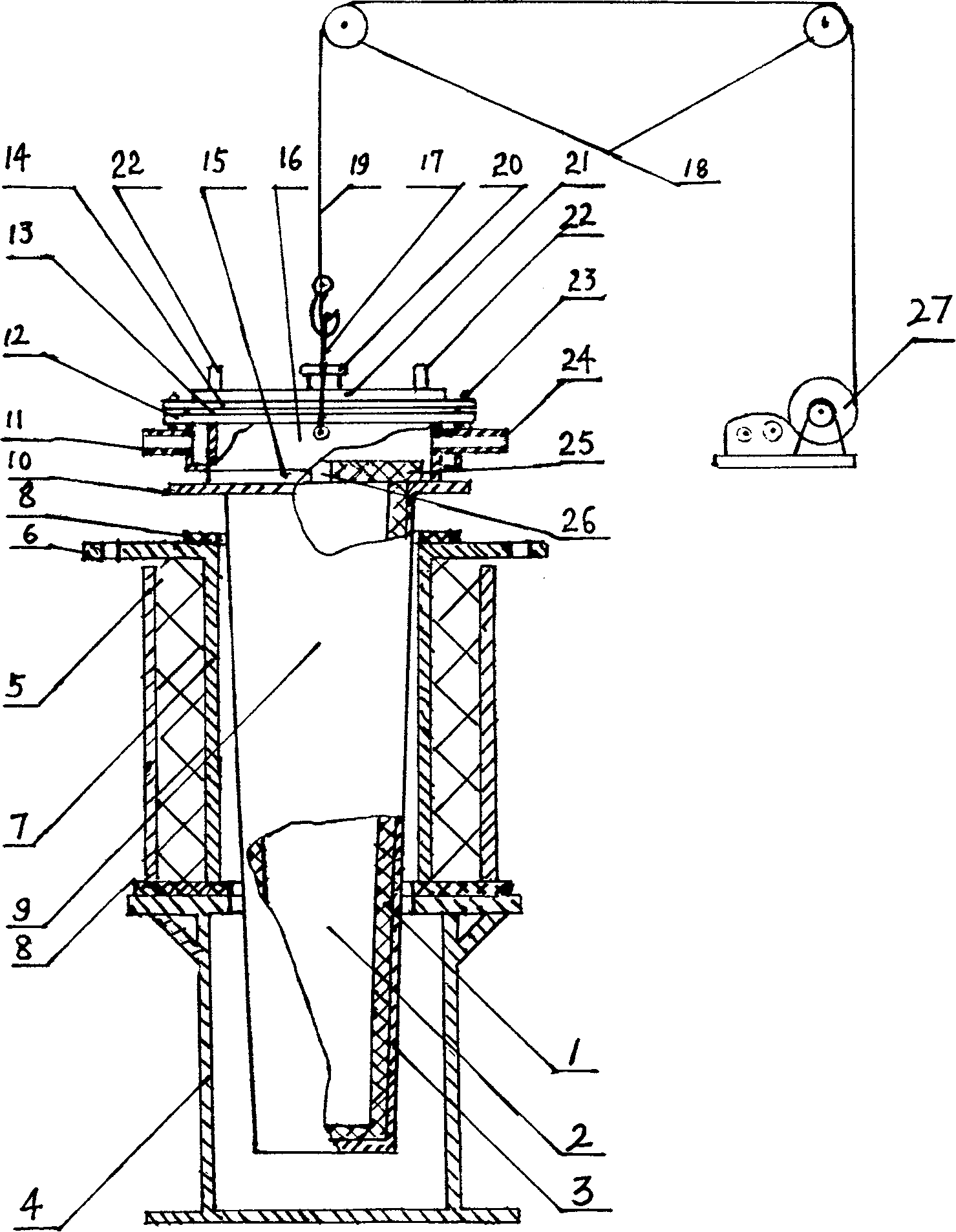

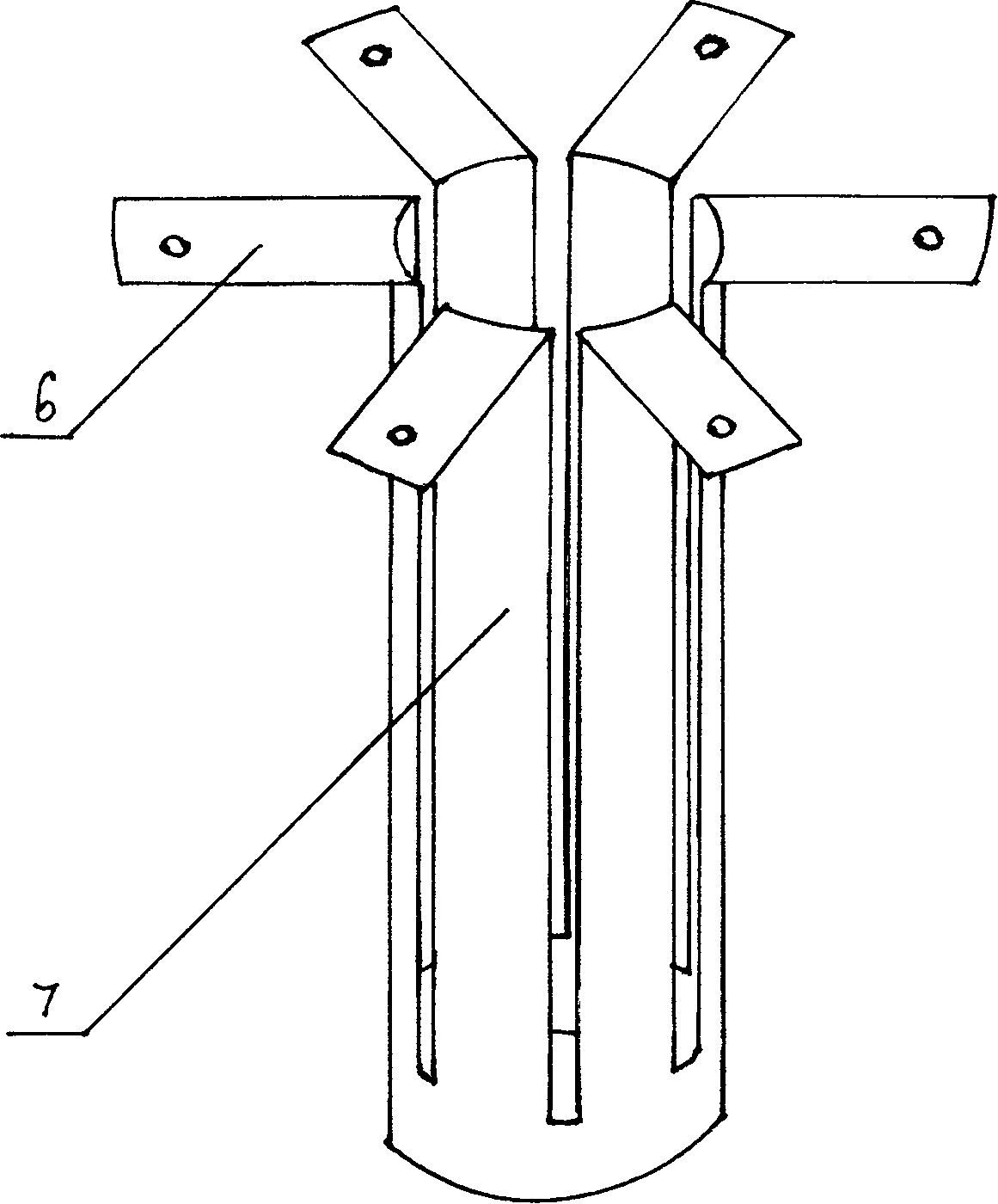

[0008] As shown in the figure, the electromagnetic induction furnace cover 7 is in the shape of a blade cylinder, and there are 6 blades on the upper end of the blade 6 which are the terminals of the three-phase electricity, and the three-phase electricity is connected to the furnace cover 7 thereby. There is a refractory insulation layer 5 on the outer side of the furnace jacket 7, and the surface of the insulation layer 5 is wrapped with metal sheets. The upper and lower ends of the furnace jacket 7 are respectively equipped with annular asbestos pads 8 for insulation and heat insulation; Under the thin frustum-shaped structure. The shell 3 of the furnace 9 is made of high-strength stainless steel plate, so that the crucible 1 in the shell has no faults when it is filled with molten aluminum, and can complete the separation and crystallization of the molten aluminum and impurities when rotating at high speed. The upper flange of the furnace 9 The sealed inlet and outlet are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com