Method for manufacturing anti-bacterial bamboo charcoal fiber yarn

A manufacturing method, bamboo charcoal fiber technology, applied in fiber treatment, fiber chemical characteristics, yarn, etc., can solve the problems of affecting functional effect, bamboo charcoal powder content can not be too high, limited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to be able to understand other features and advantages of the present invention and the achieved effects conveniently and concisely, the present invention will be described in detail as follows in conjunction with the accompanying drawings:

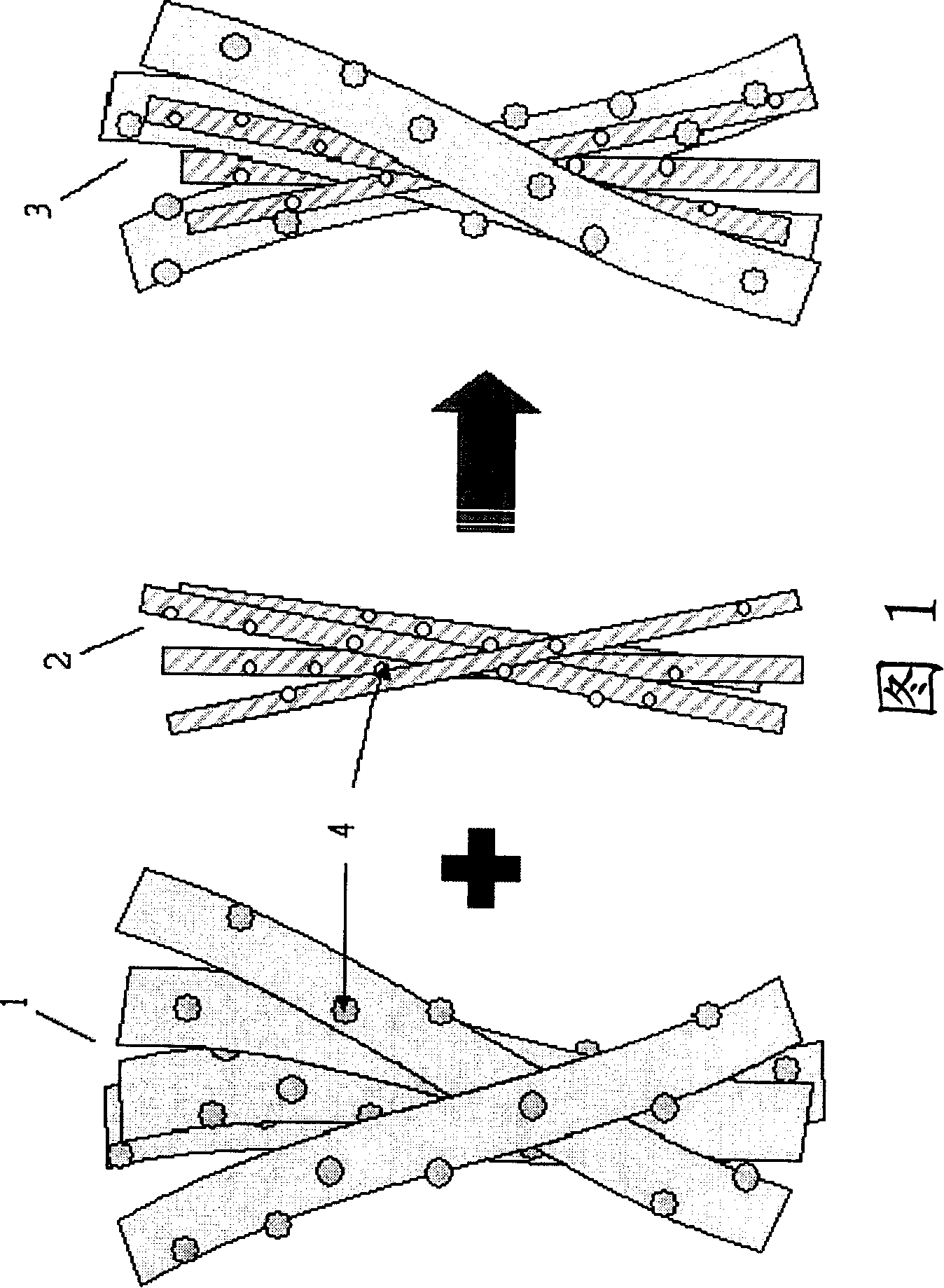

[0019] The present invention provides a kind of manufacture method of antibacterial bamboo charcoal fiber yarn, and it mainly is to use the bamboo charcoal fiber bundle 2 that bamboo fiber carbonization forms and other fiber bundle 1 to blend to form tool functional blended yarn 3, as shown in Figure 1, this Bamboo fiber carbonization forms bamboo charcoal fiber, and described other fiber can be natural fiber, the chemical fiber that contains functional powder or general chemical synthetic fiber, and this antibacterial powder 4 can exist on this bamboo charcoal fiber surface or other fiber surfaces, and this Bamboo charcoal fiber bundles 2 and other fiber bundles 1 are twisted and mixed to form a multifunctional blended yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com