Metal conducting wire mosaic structure and method of manufacture

A technology of metal wires and inlaid structures, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of RC delay and large leakage current, and reduce RC delay and leakage current, Guaranteed accuracy and reduced effects of capacitive coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

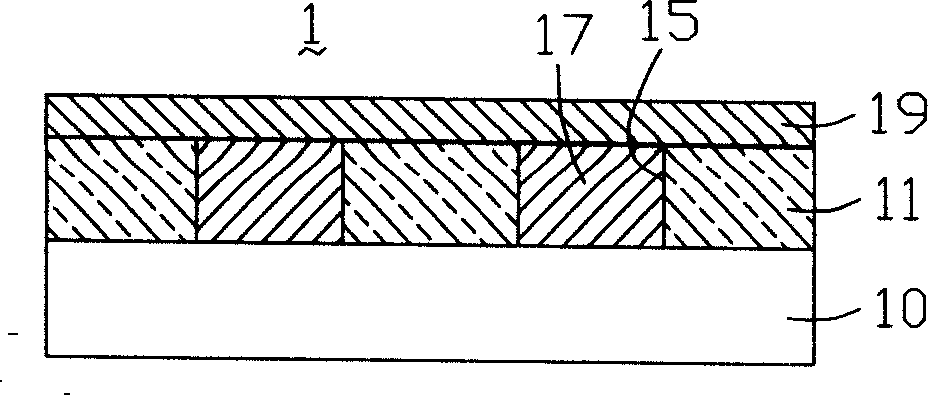

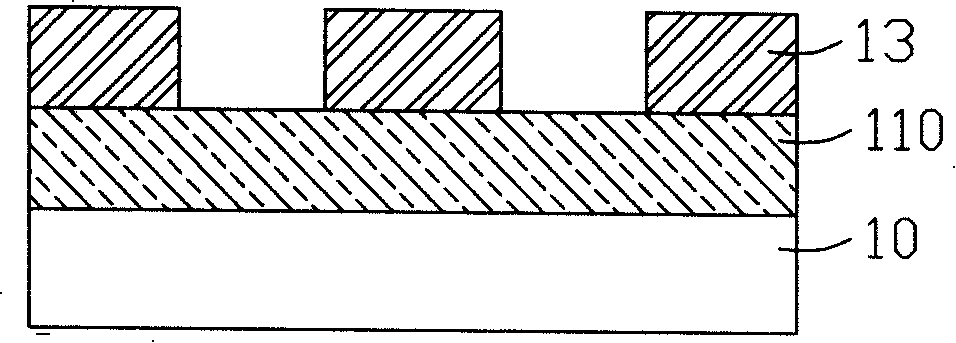

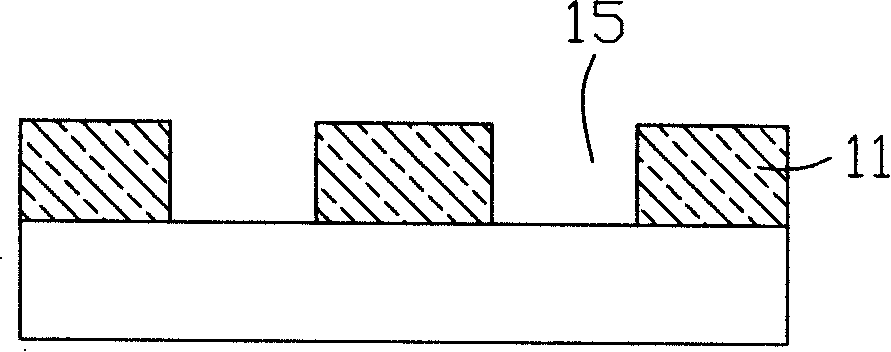

[0025] Please refer to Figure 6 , which is a structural schematic diagram of a preferred embodiment of the metal wire damascene structure of the present invention. The metal wire mosaic structure 2 includes a substrate 20, a first dielectric layer 21 is disposed on the substrate 20, the first dielectric layer 21 has a plurality of grooves 27, and a plurality of metal wires are embedded in the plurality of grooves 27. twenty four. A cover layer 25 is disposed on the first dielectric layer 21 and the metal wire 24 , and the cover layer 25 is used to protect the metal wire 24 and block the diffusion of the metal wire 24 . A second dielectric layer 26 is disposed on the cover layer 25 , and the second dielectric layer 26 is used to insulate the plurality of metal wires 24 from other electronic devices.

[0026] Wherein, the first dielectric layer 21 includes a first sub-dielectric layer 211, a second sub-dielectric layer 212 and a third sub-dielectric layer 213 stacked, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com