Full-automatic on-line method for gag press straightening jackrod

A fully automatic, straightening technology, applied in the mechanical field, can solve problems such as poor straightness at the end of drill pipes, and achieve the effects of straightness out-of-tolerance, high precision, and high production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

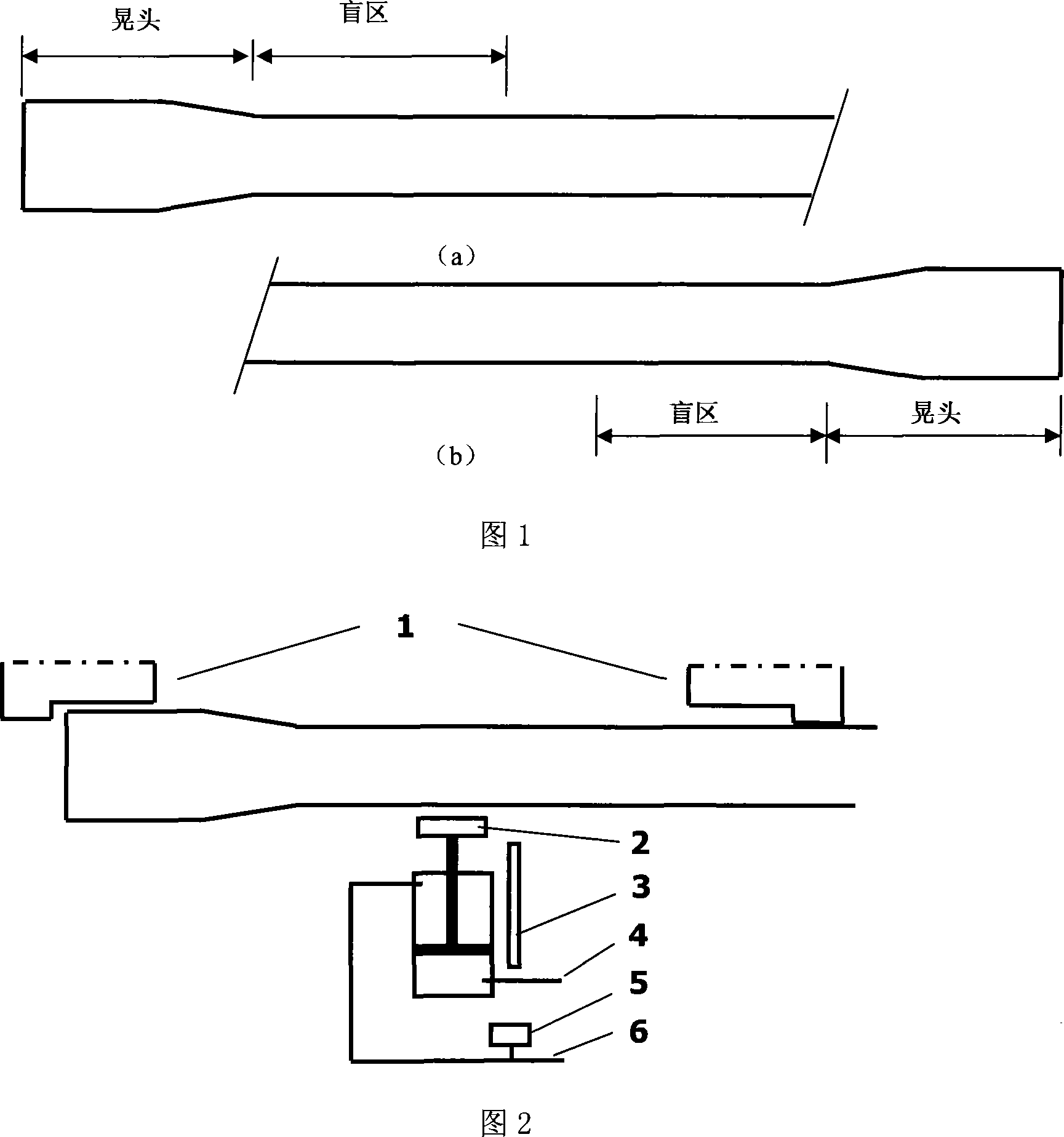

Image

Examples

Embodiment

[0033] In this embodiment, the specifications of the drill pipe are selected: outer diameter 127mm, steel grade G105, wall thickness 9.19mm, ambient temperature 20 degrees, drill pipe temperature 20 degrees, straightening method is straightening at both ends. Test indicators: the runout at the 30mm end of the pipe is less than 2mm, and the runout at the 366mm end of the pipe is less than 1.2mm. The initial straightening parameters are all 6mm, after one hour of parameter self-learning. Actual production of a class, implementation effect comparison:

[0034] In this embodiment: all the drill pipes meet the inspection requirements, and the production cycle is 2 minutes per piece. After pressure straightening, the surface of the drill pipe is intact, which can effectively straighten the curved part.

[0035] Traditional method: a small number of drill pipes do not meet the inspection requirements, and the production cycle: 3 minutes per piece. Some drill pipes are damaged due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com