Method of testing self-changing gearbox oil pump assembly

A technology of automatic transmission and test method, which is applied in the direction of pump test, machine/engine, liquid variable displacement machinery, etc., to achieve the effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

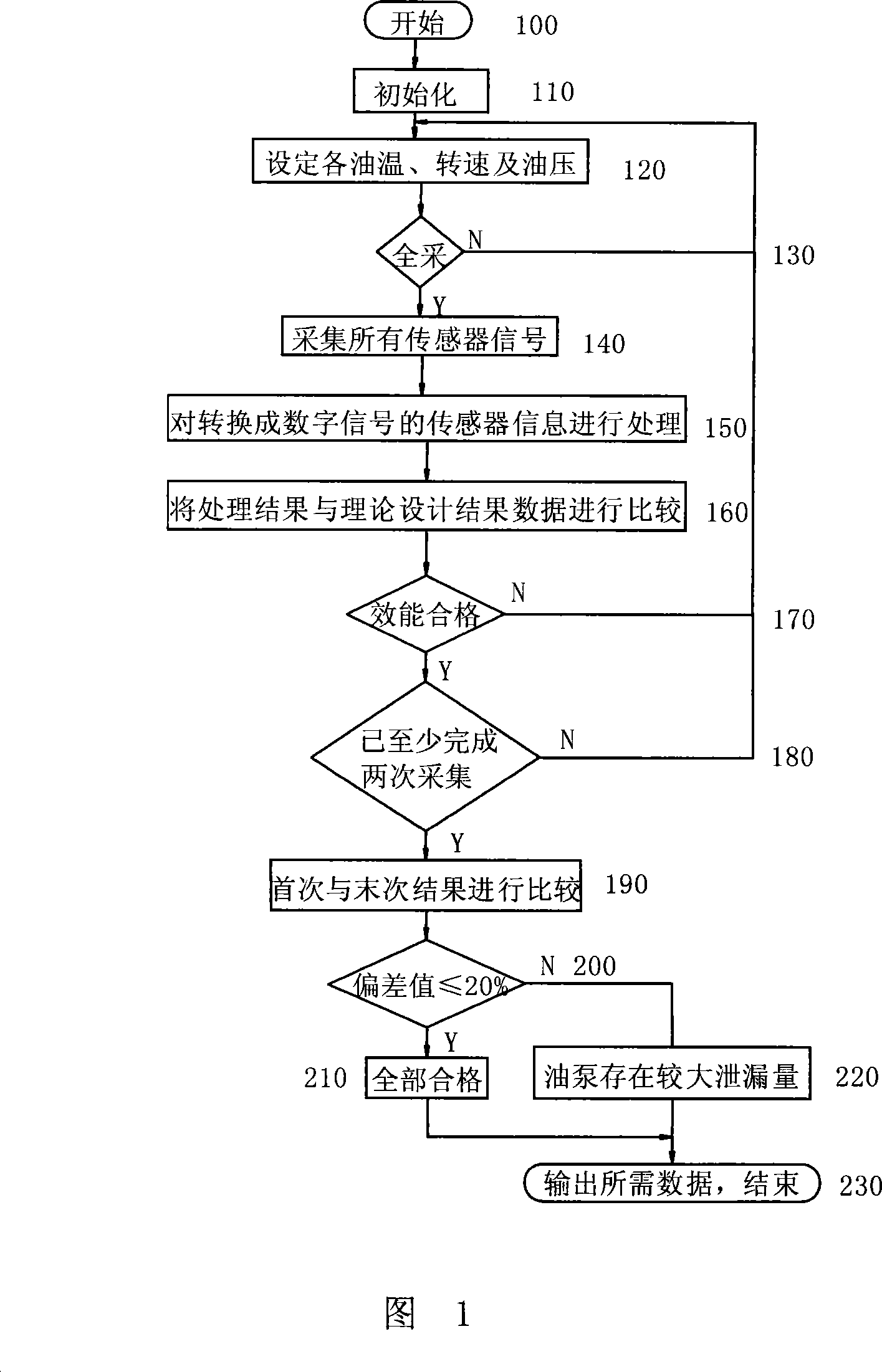

Method used

Image

Examples

Embodiment Construction

[0016] The test item carried out by adopting the present invention is the basic performance test of the oil pump assembly.

[0017] First, you must make preparations for the test. The specific instructions are as follows:

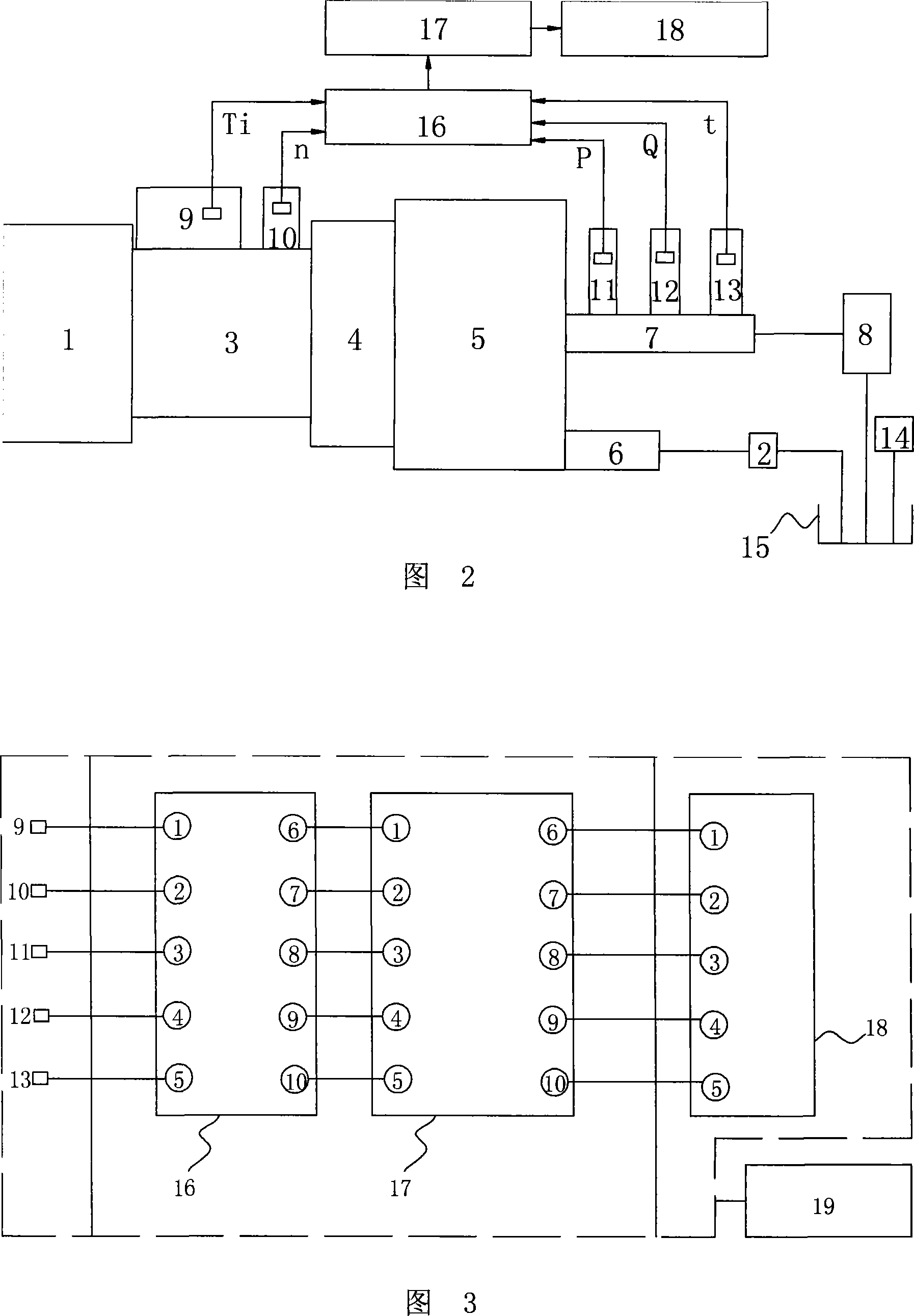

[0018] Test bench preparation, motor-driven unit operation test bench, including oil pump drive, matching tooling, output oil pressure regulating valve, oil pressure sensor, speed sensor, thermometer, torque meter, and hydraulic output device that can be closed-loop controlled.

[0019] The oil pump assembly uses a single running test bench.

[0020] The accuracy and operation of the above-mentioned equipment and measuring instruments need to be checked regularly.

[0021] Equipment performance: The maximum speed is 9000rpm, the maximum measurement pressure is 10.0MPa, the maximum flow rate is 120L / min, and the temperature range is -40~145℃.

[0022] Test oil pump preparation. Oil pump sampling: The oil pump sampling method should be tested immediately, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com