Light diffuser plate, surface emission light source apparatus and liquid crystal display

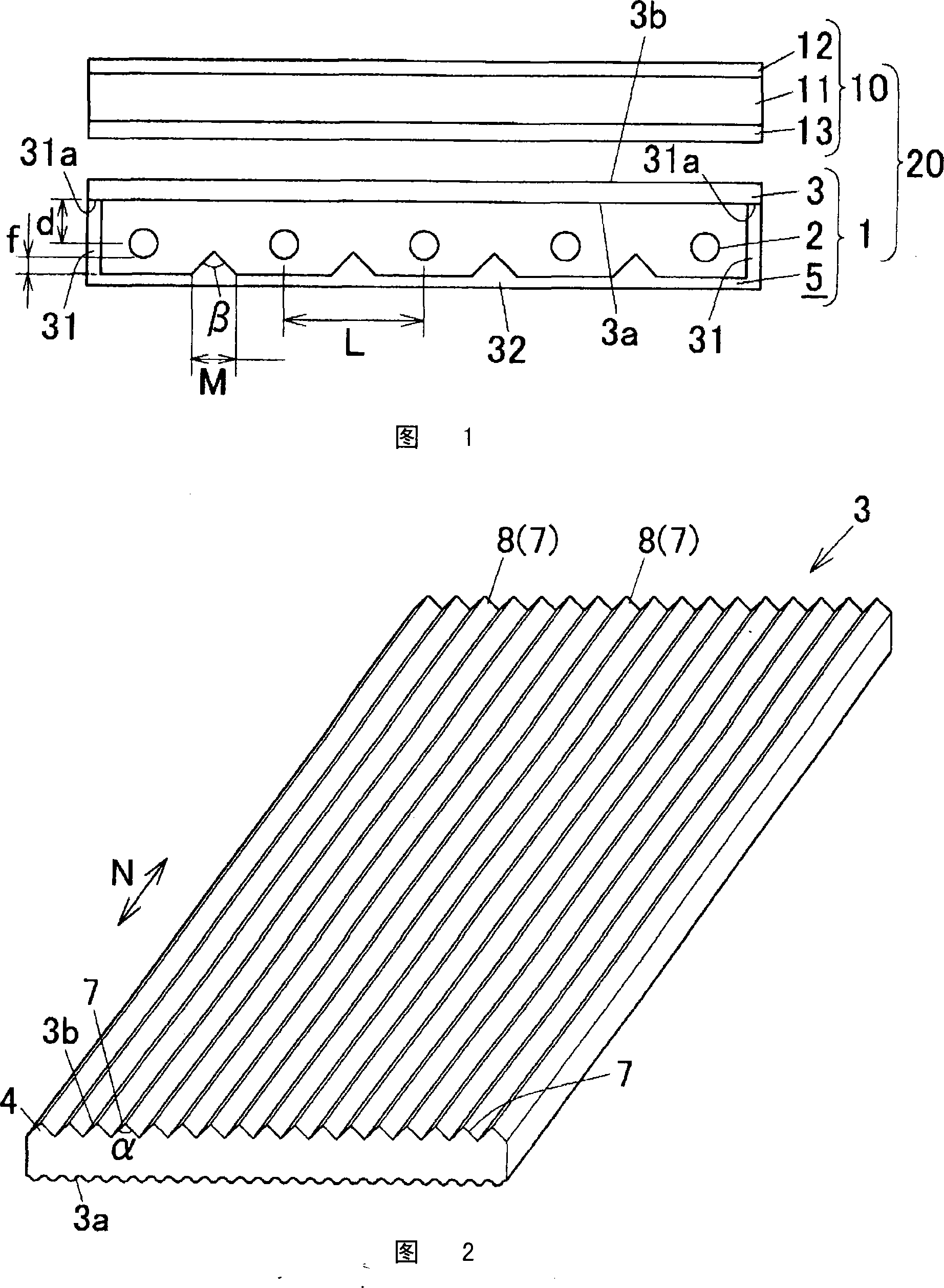

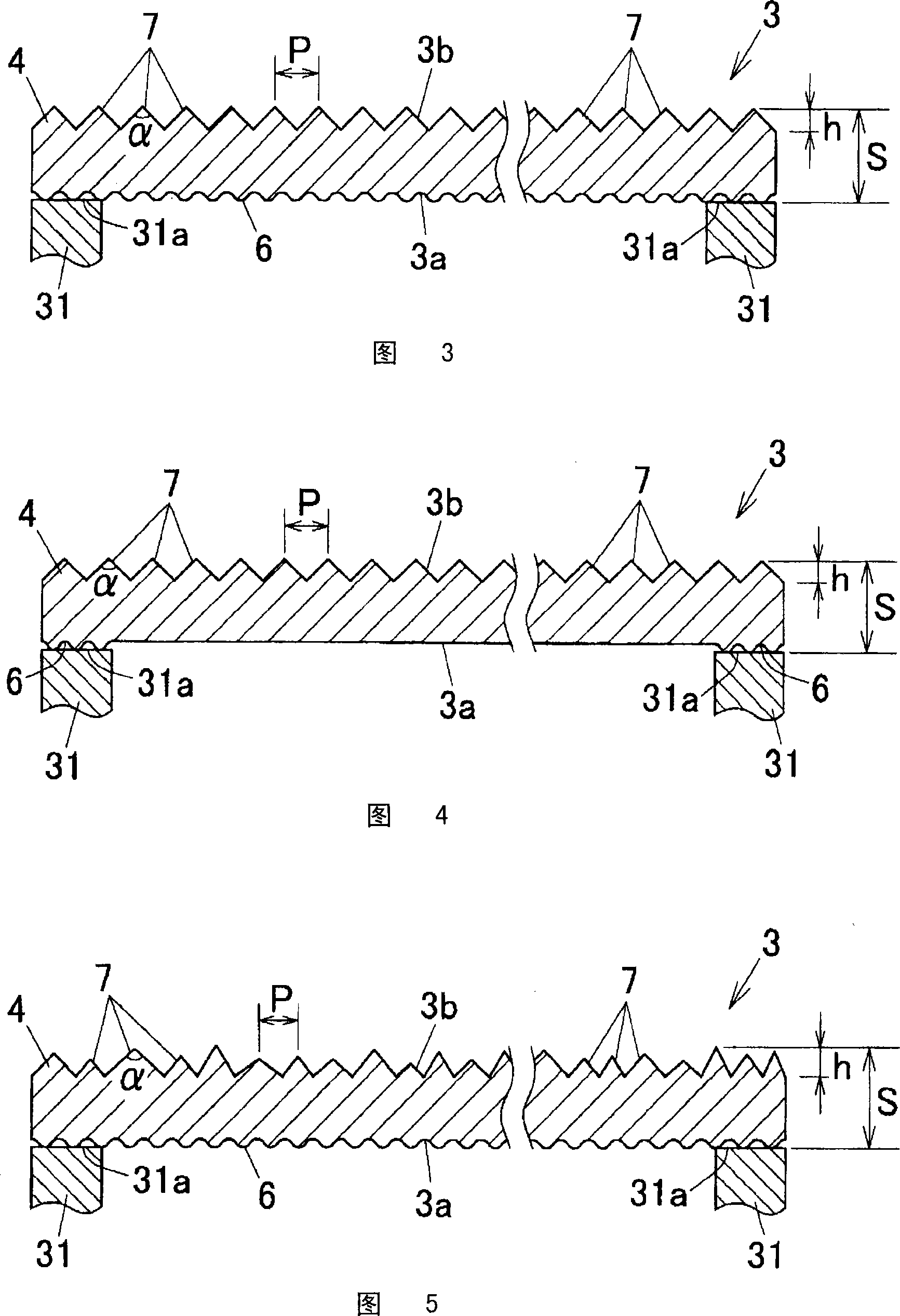

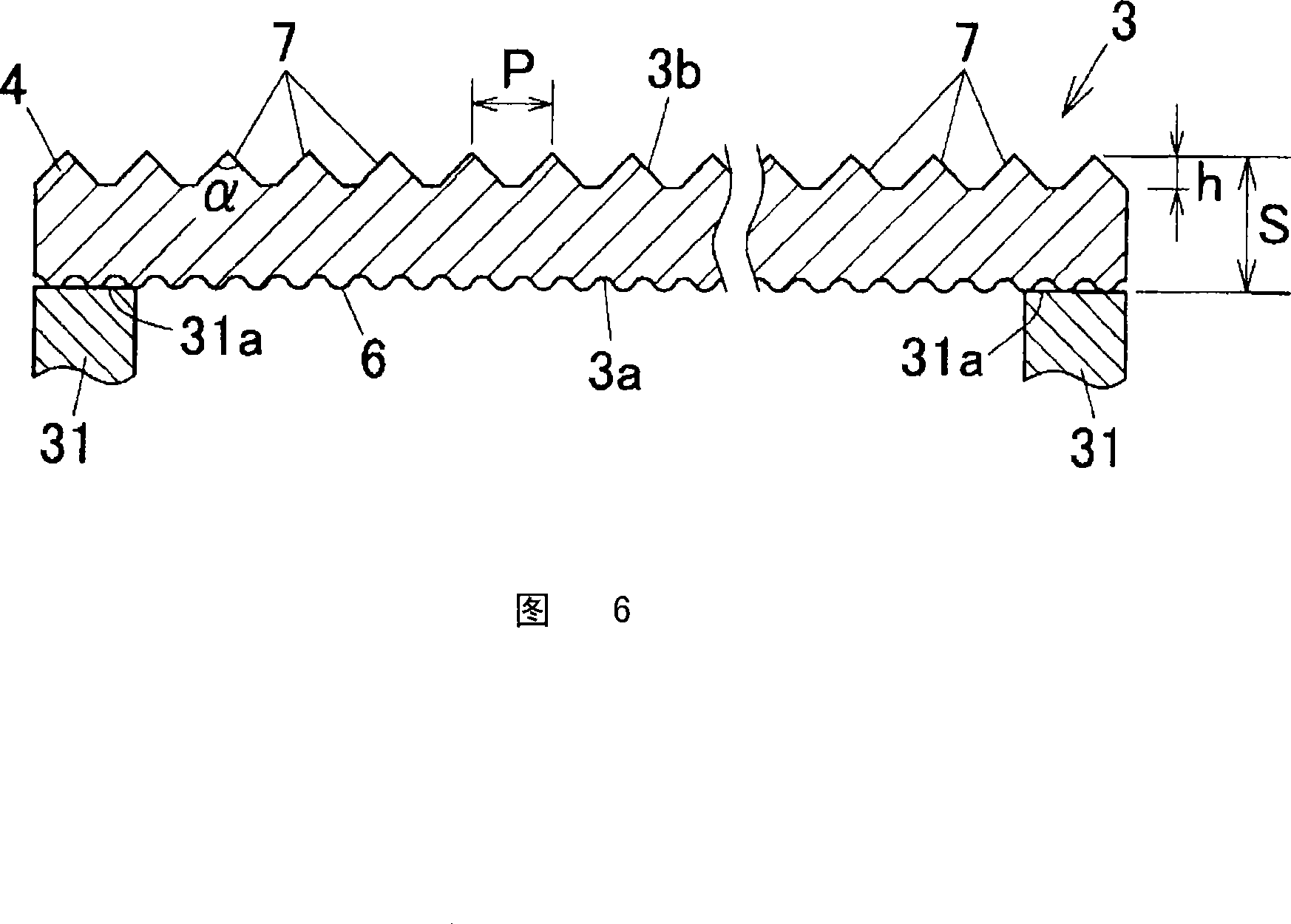

A surface-emitting, light-diffusing plate technology, used in mechanical equipment, static indicators, lighting and heating equipment, etc., can solve problems such as annoying noise, light-diffusing plate expansion, etc., to prevent noise and improve brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0136] Examples of the present invention will now be described, however, it should be understood that the present invention is not limited to these examples.

[0137] raw material

[0138] Translucent resin A: styrene resin ("HRM40" manufactured by Toyo Styrene Co., Ltd., refractive index 1.59)

[0139] Translucent resin B: MS resin ("MS200NT" manufactured by Nippon Steel Chemical Co., Ltd., refractive index 1.57, styrene / methyl methacrylate=80 parts by mass / 20 parts by mass)

[0140] Light-diffusing agent A: crosslinked PMMA particles ("Sumipex XClA" manufactured by Sumitomo Chemical Co., Ltd., refractive index 1.49, average particle size by weight 35 μm)

[0141] Light diffusing agent B: crosslinked silicone polymer particles ("Torayfil DY33-719" manufactured by Toray Dow Coming Inc., refractive index 1.42, volume average particle size 2 µm)

[0142] Light diffusing agent C: "KE-P50" manufactured by Nippon Shokubai Co., Ltd. (refractive index 1.43, average particle size 0....

example A1

[0148] Mix 97.0 parts by mass of translucent resin A and 3.0 parts by mass of light diffusing agent masterbatch A in a dry process, and melt and mix the mixture in the first extrusion machine, and provide it to the feed head, the machine The cylinder temperature is set in the range of 190 to 250°C. At the same time the light diffusing agent masterbatch B was melted and mixed in the second extrusion machine, and supplied to the feed block, the cylinder temperature of which machine was set in the range of 190 to 250°C.

[0149] The co-extrusion molding operation is carried out by utilizing a multi-manifold die at an extrusion temperature of 250° C. so that the resin supplied to the feed block by the first extrusion machine can form an intermediate layer (base layer), and The resin supplied to the feedblock by the second extrusion machine may form the skin. These layers are pressed together by polishing rolls and cooled, thereby producing a light-diffusing plate 3 consisting of ...

example A2

[0152] Mix 97.0 parts by mass of translucent resin A and 4.5 parts by mass of light diffusing agent masterbatch A in a dry process, and melt and mix the mixture in the first extrusion machine, and provide it to the feed head, the machine The cylinder temperature is set in the range of 190 to 250°C. At the same time the light diffusing agent masterbatch B was melted and mixed in the second extrusion machine, and supplied to the feed block, the cylinder temperature of which machine was set in the range of 190 to 250°C.

[0153] The co-extrusion molding operation is realized by using multiple multi-pipe dies at an extrusion temperature of 250°C, so that the resin supplied to the feed block by the first extrusion machine can form the middle layer (base layer), and the resin supplied by the second extrusion machine The resin supplied to the feedblock may form the skin. These layers were pressed together by polishing rolls and cooled, thereby producing a light-diffusing plate 3 con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com