Ultrasonic sensor

A sensor and ultrasonic technology, applied in the field of coupling layer, can solve the problems of uneven distribution of bubble diameters in coupling parts, low production efficiency of coupling parts, limited part of coupling parts, etc., and achieve the effect of improving production stability, improving productivity and a certain speed of sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

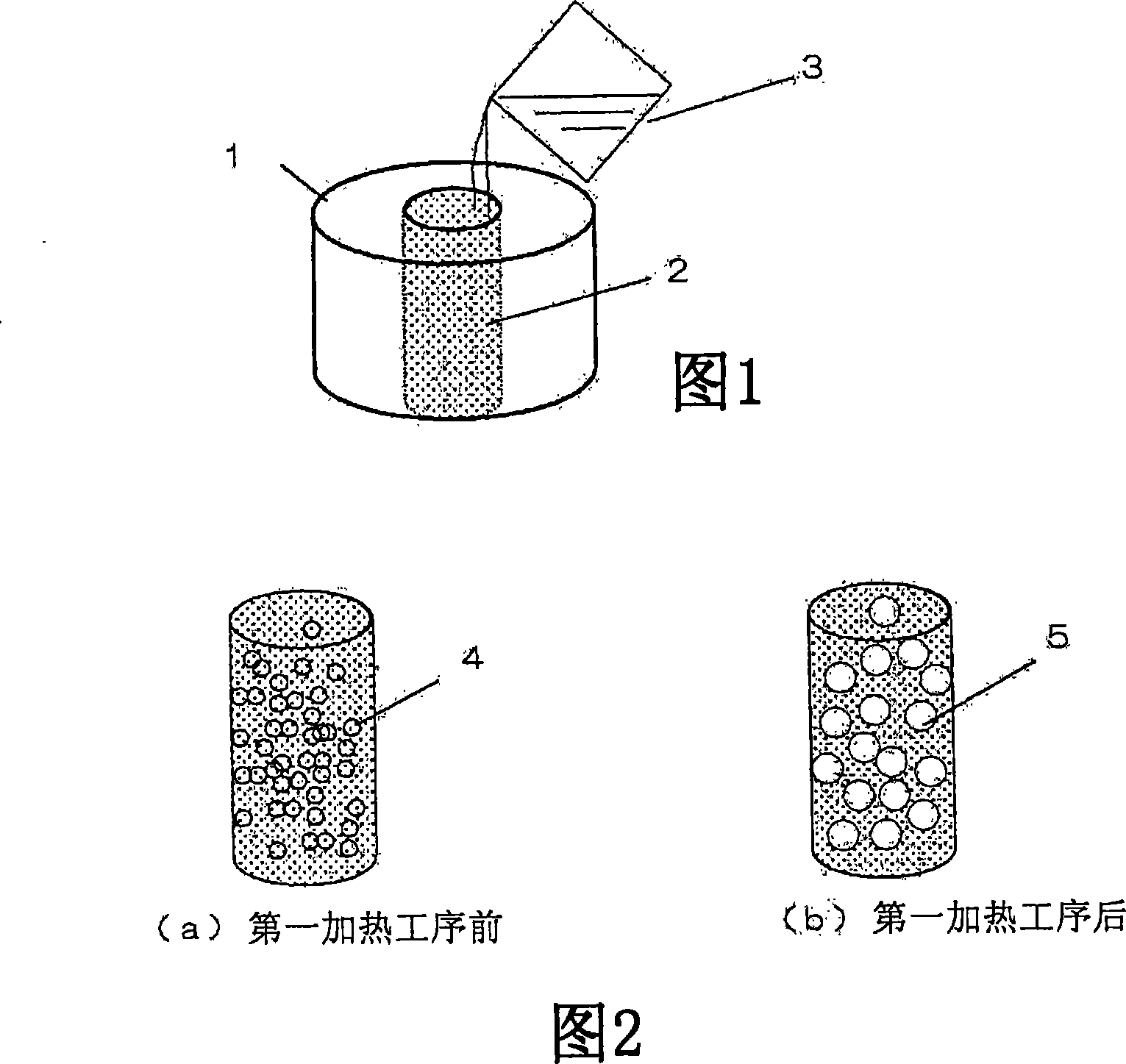

[0032] FIG. 1 shows the flow of the manufacturing method of the coupling member and the coupling layer in the first embodiment of the present invention in a schematic process diagram.

[0033] Inside the container 1 shown in FIG. 1 there is a storage chamber 2 with a predetermined volume. In the above-mentioned storage chamber 2, a slurry 3 containing a hollow spherical resin is stored. The slurry 3 is mixed with oxide ceramics such as silicon carbide. Inorganic material, water or organic solvent, and gelling agent are used to make a slurry, and hollow spheres (particles) of resin containing liquefied gas are contained in the slurry. The hollow spherical resin-containing slurry 3 injected into the container 1 is shaped into the shape of the container 2, and after the heating step, the slurry is oxidized and fired to obtain a ceramic porous body.

[0034] The manufacturing method of the hollow sphere resin-containing slurry of the present invention is: mixing inorganic material...

no. 2 approach

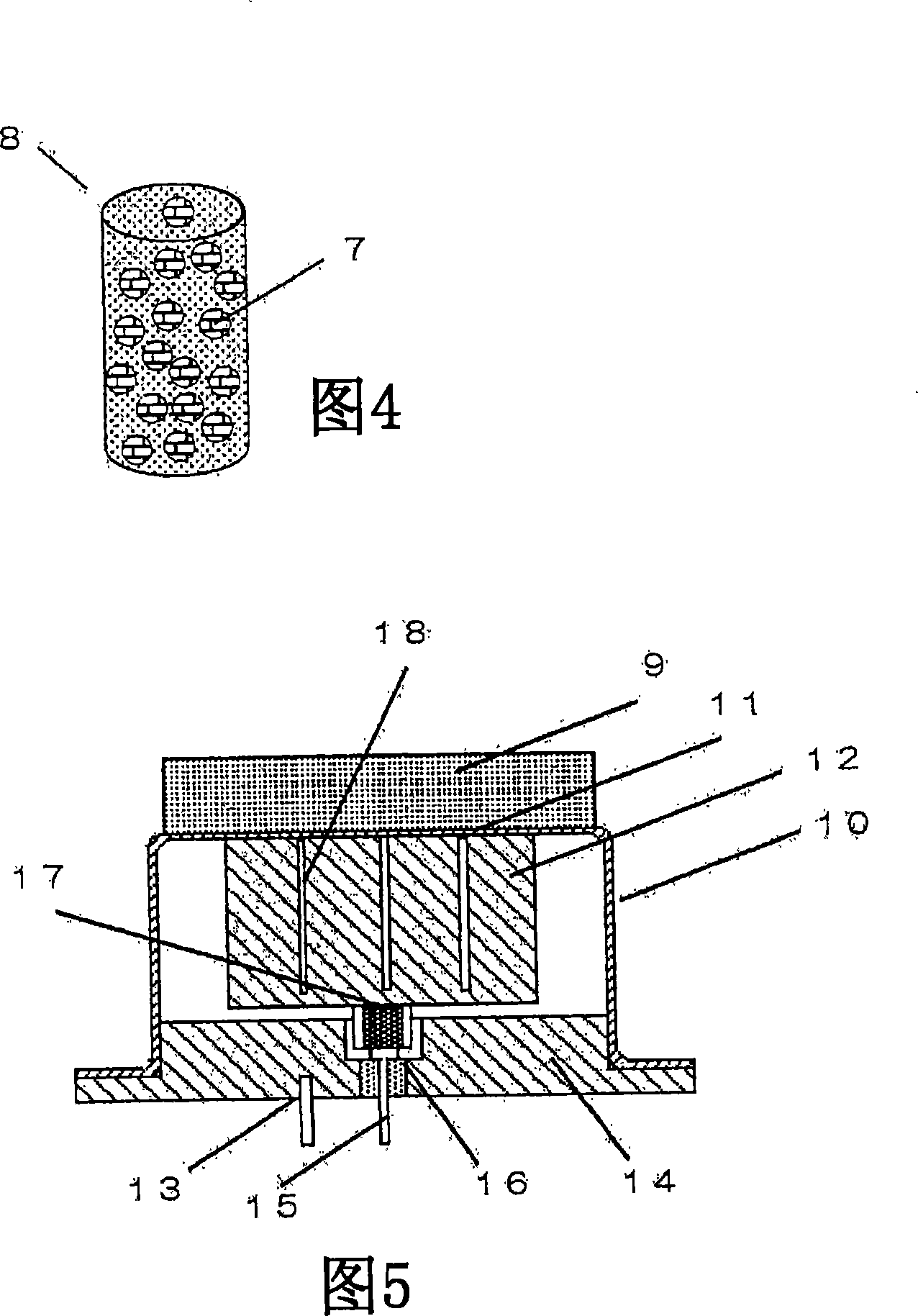

[0049] FIG. 5 is a cross-sectional view of an ultrasonic sensor using the coupling layer 9 obtained in the above embodiment.

[0050] A cylindrical case 10 made of a conductive material has a top 11, a piezoelectric body 12 is bonded to an inner wall surface of the top 11, and a coupling layer 9 is bonded to an outer wall surface.

[0051] The lower opening of the cylindrical casing 10 is closed by the terminal plate 14 connected to the terminal 13 on one side, and the terminal 15 on the other side passes through the terminal plate 14 through the electrical insulating material 16, and is connected to the conductor 17, and the conductor 17 is connected to the pressure. The lower surface of the electric body 12 is in contact. A plurality of vertical grooves 18 are formed in the piezoelectric body 12 .

[0052] When a voltage is applied from the terminals 13 and 15 to the piezoelectric body 12 via the conductor 17, the piezoelectric body 12 vibrates due to a piezoelectric phenom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com