Method for forming interlaminar capacitor

A technology for capacitors and capacitor dielectrics, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of complex formation processes, and achieve the effect of simplifying the process flow and reducing the number of deposition and etching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

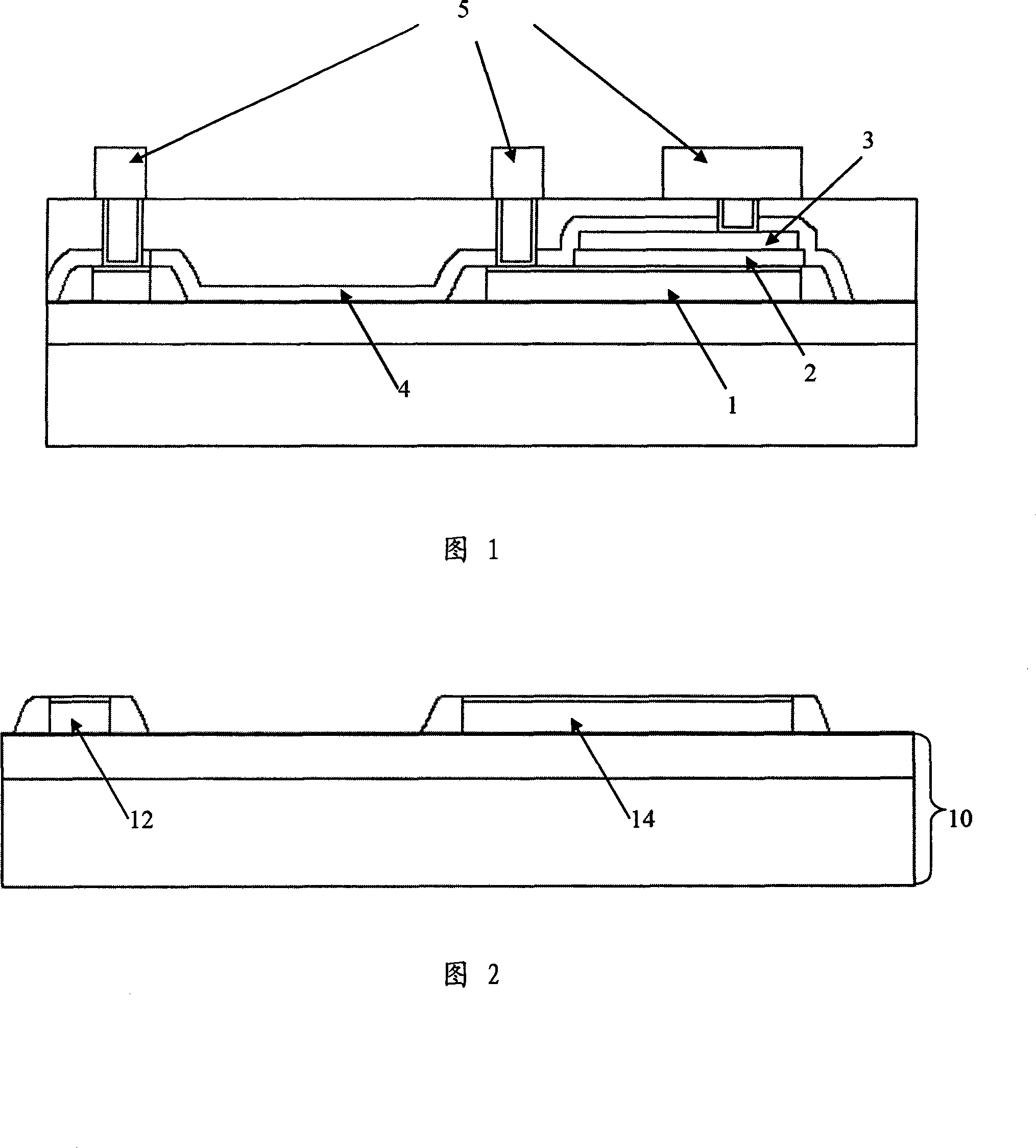

[0030] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

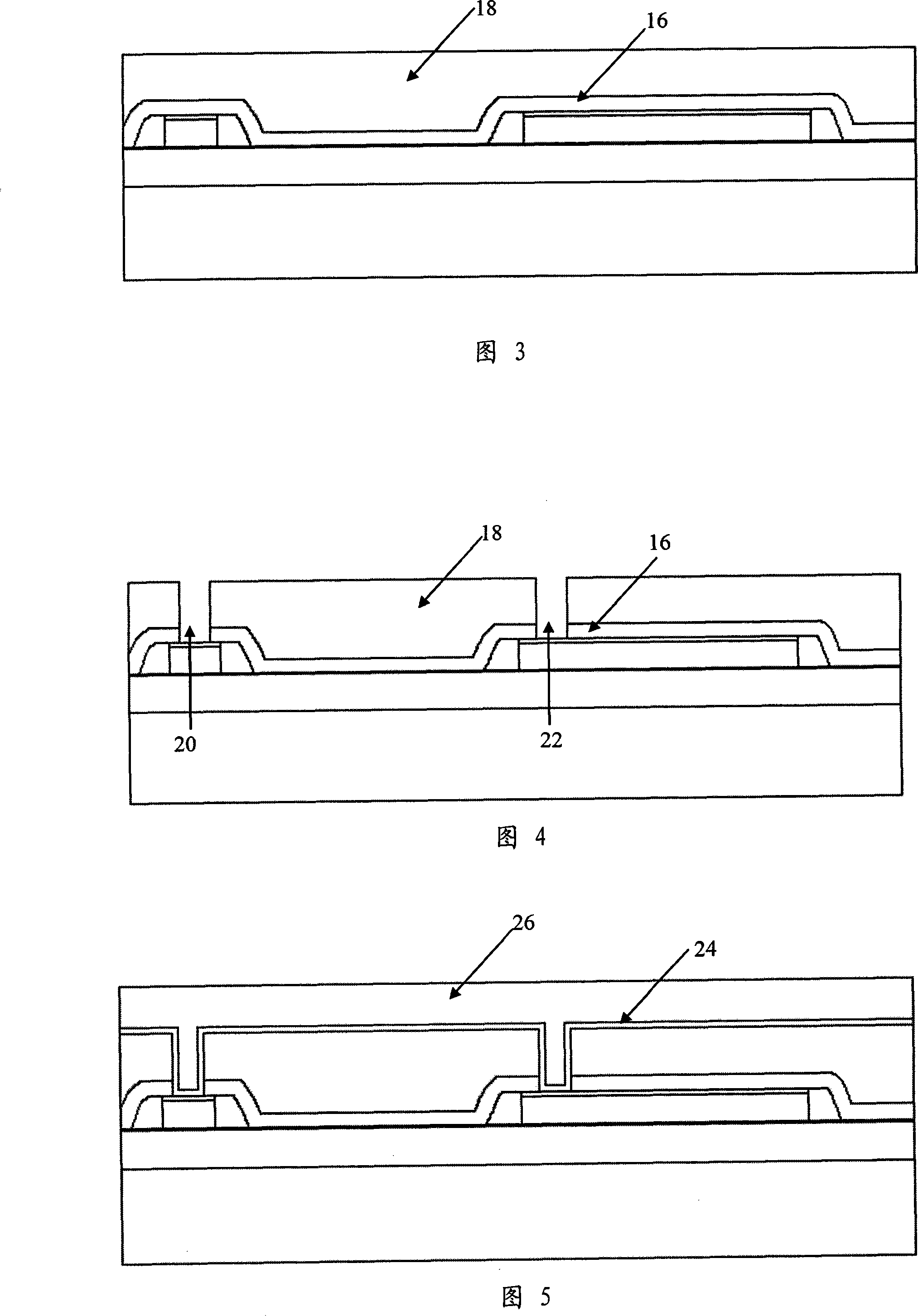

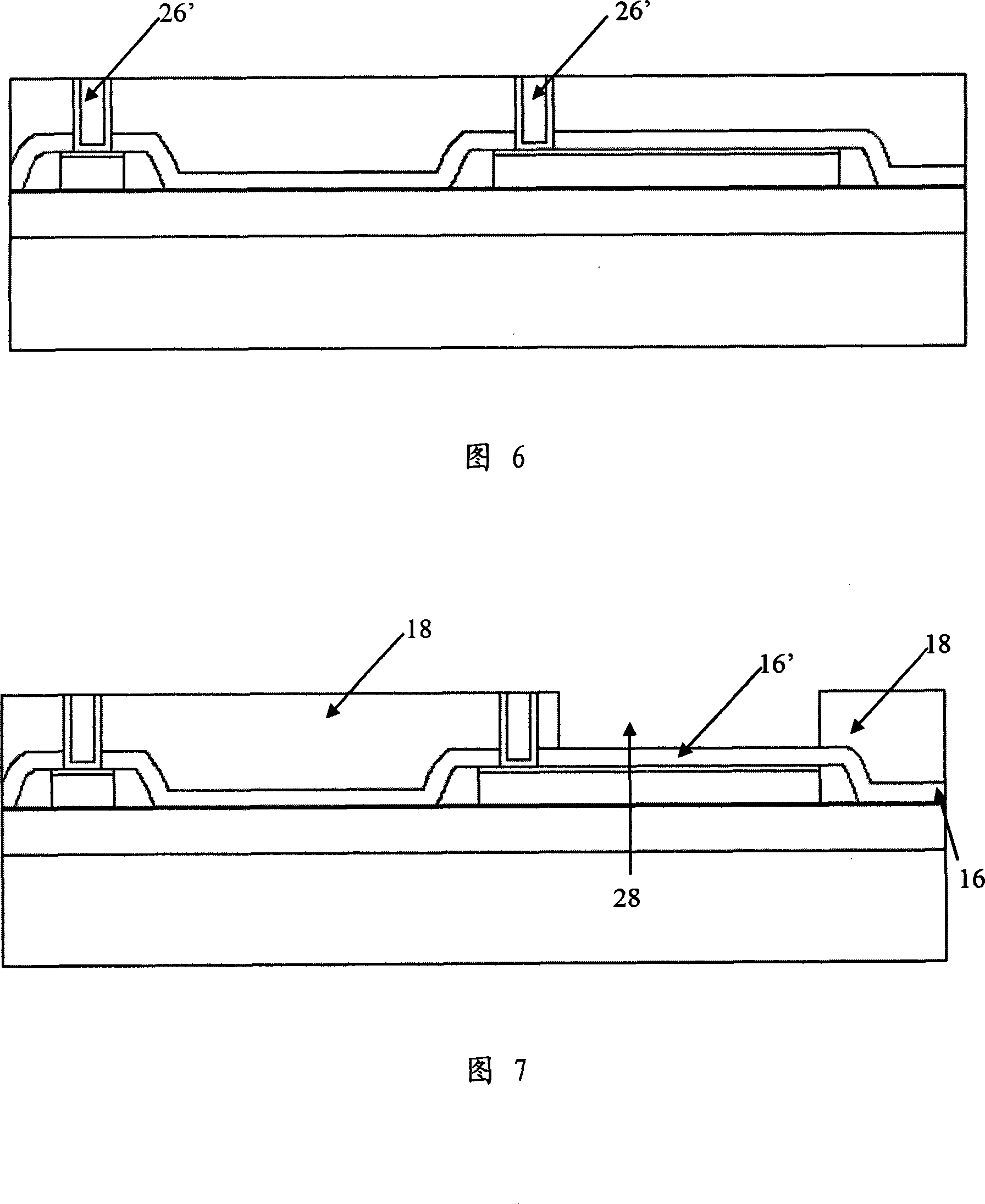

[0031] Please refer to FIG. 2 to FIG. 10 , which are schematic diagrams of the formation process of the interlayer capacitor according to an embodiment of the present invention. details as follows:

[0032] First, form the gate 12 and the lower plate 14 of the capacitor on the substrate 10 (as shown in FIG. 2); The electrode 12 and the lower plate 14 of the capacitor can then enter the traditional sidewall formation and silicide formation process, forming sidewalls on the side walls of the grid 12 and the lower plate 14 of the capacitor, and forming a silicide layer on the upper surface. Next, an etch stop layer 16 and an interlayer dielectric film 18 are deposited (as shown in FIG. 3 ). Then contact holes 20 and 22 are formed in the interlay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com