Voltage conversion device

A voltage conversion and voltage converter technology, which is applied to output power conversion devices, regulating electrical variables, electric vehicles, etc., can solve problems such as infeasible response time management, achieve control response capabilities, reduce capacitance, and prevent delays Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now, embodiments of the present invention will be described in detail with reference to the accompanying drawings. Note that the same symbols in the drawings indicate the same or corresponding parts.

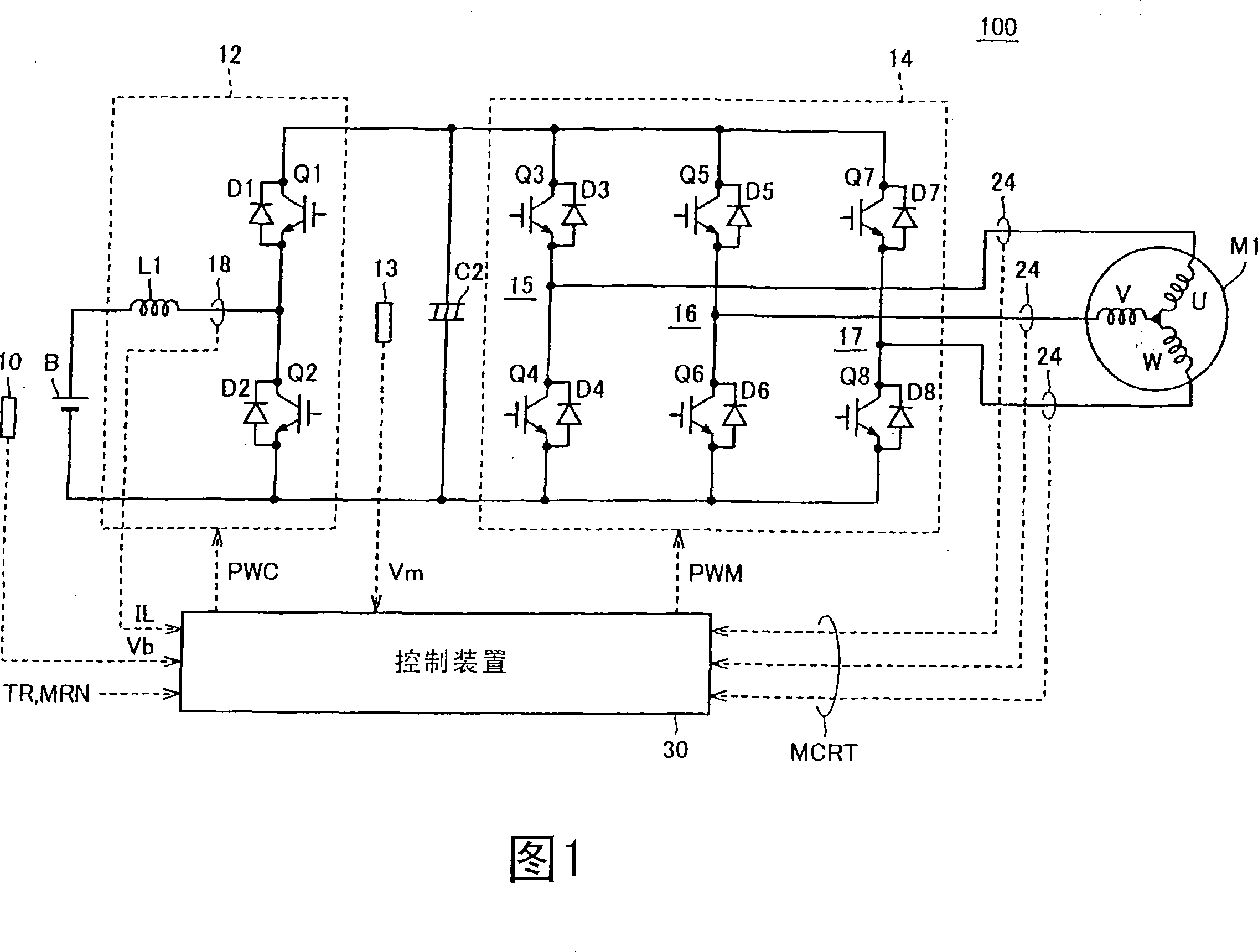

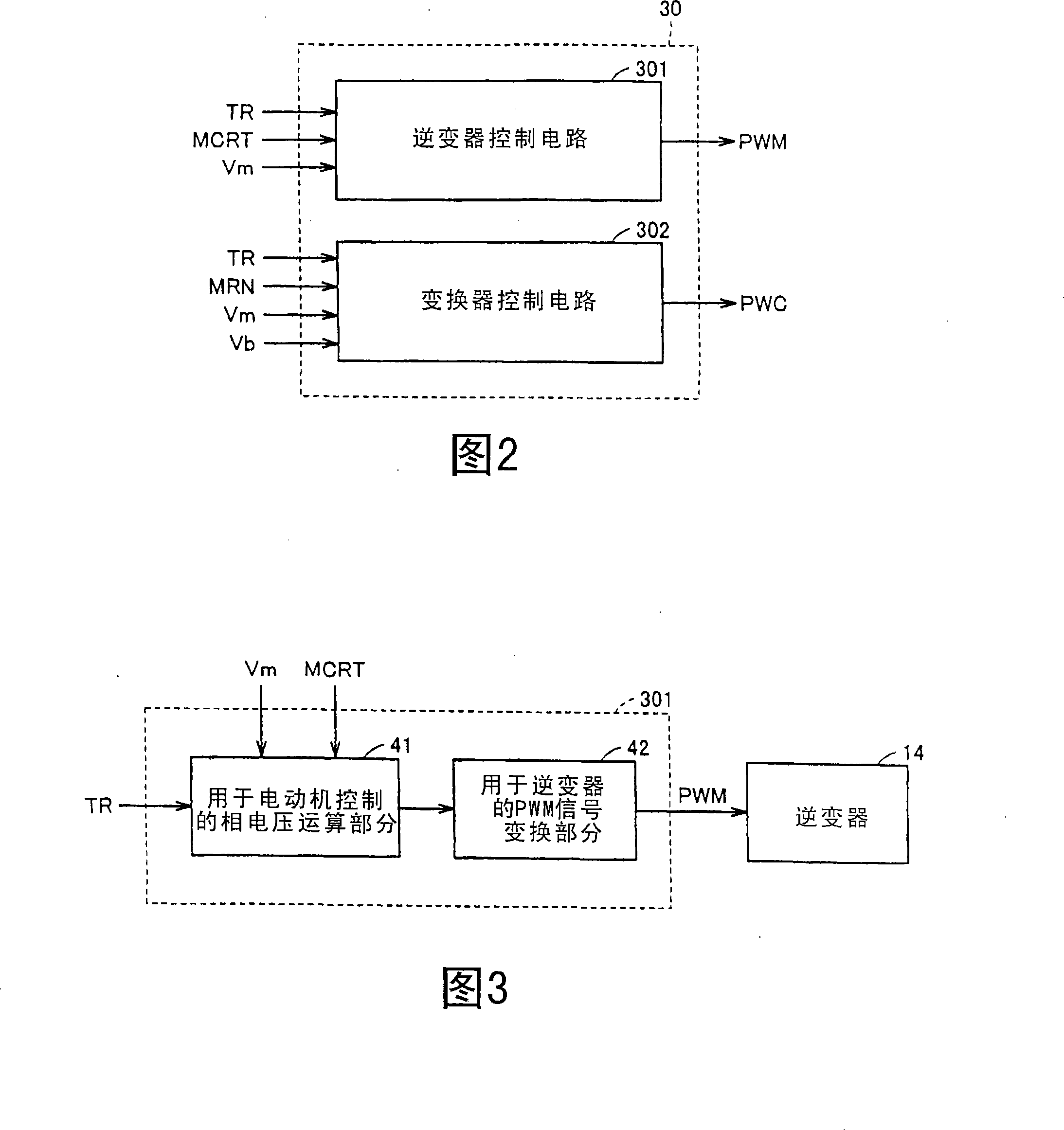

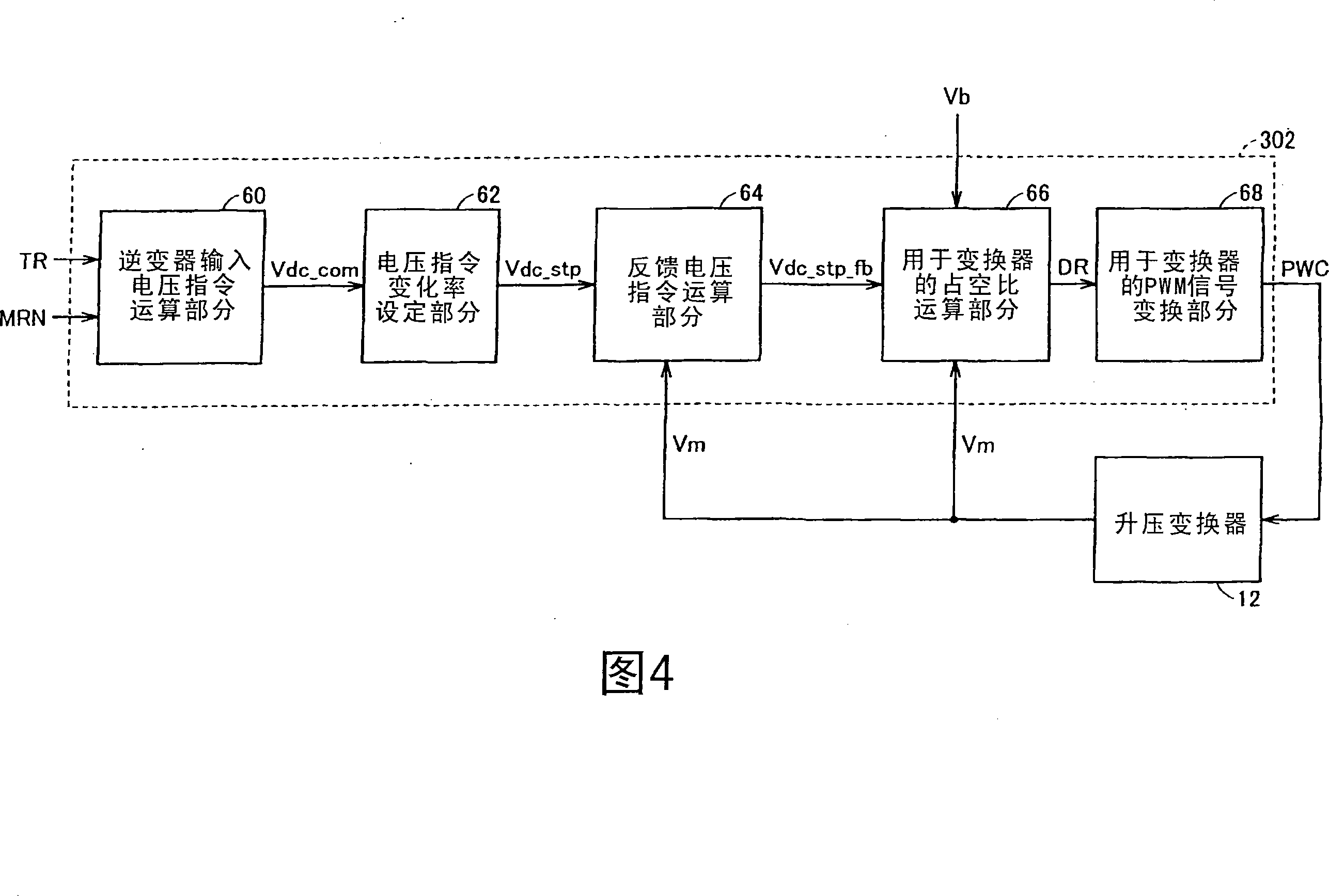

[0032] FIG. 1 is a schematic block diagram of a motor drive device to which a voltage conversion device according to an embodiment of the present invention is applied.

[0033] Referring to FIG. 1 , motor driving device 100 includes DC power supply B, voltage sensors 10 , 13 , current sensors 18 , 24 , capacitor C2 , boost converter 12 , inverter 14 and control device 30 .

[0034] The AC motor M1 is a drive motor for generating torque for driving drive wheels of a hybrid vehicle or an electric vehicle. The AC electric motor M1 also has the function of a generator driven by the engine, and can operate as an electric motor for the engine to perform starting of the engine, for example.

[0035] Boost converter 12 includes reactor L1, NPN transistors Q1, Q2 and diodes D1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com