Thin-phase combustion method for realizing low-emission of diesel engine and apparatus thereof

A technology of diesel engine and combustion method, which is applied in the direction of exhaust device, engine components, combustion engine, etc., which can solve the problems of narrow operating range of diesel engine, difficult control of ignition angle, low compression ratio, etc., easy control of ignition angle and avoiding advance Fire phenomenon, exhaust emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

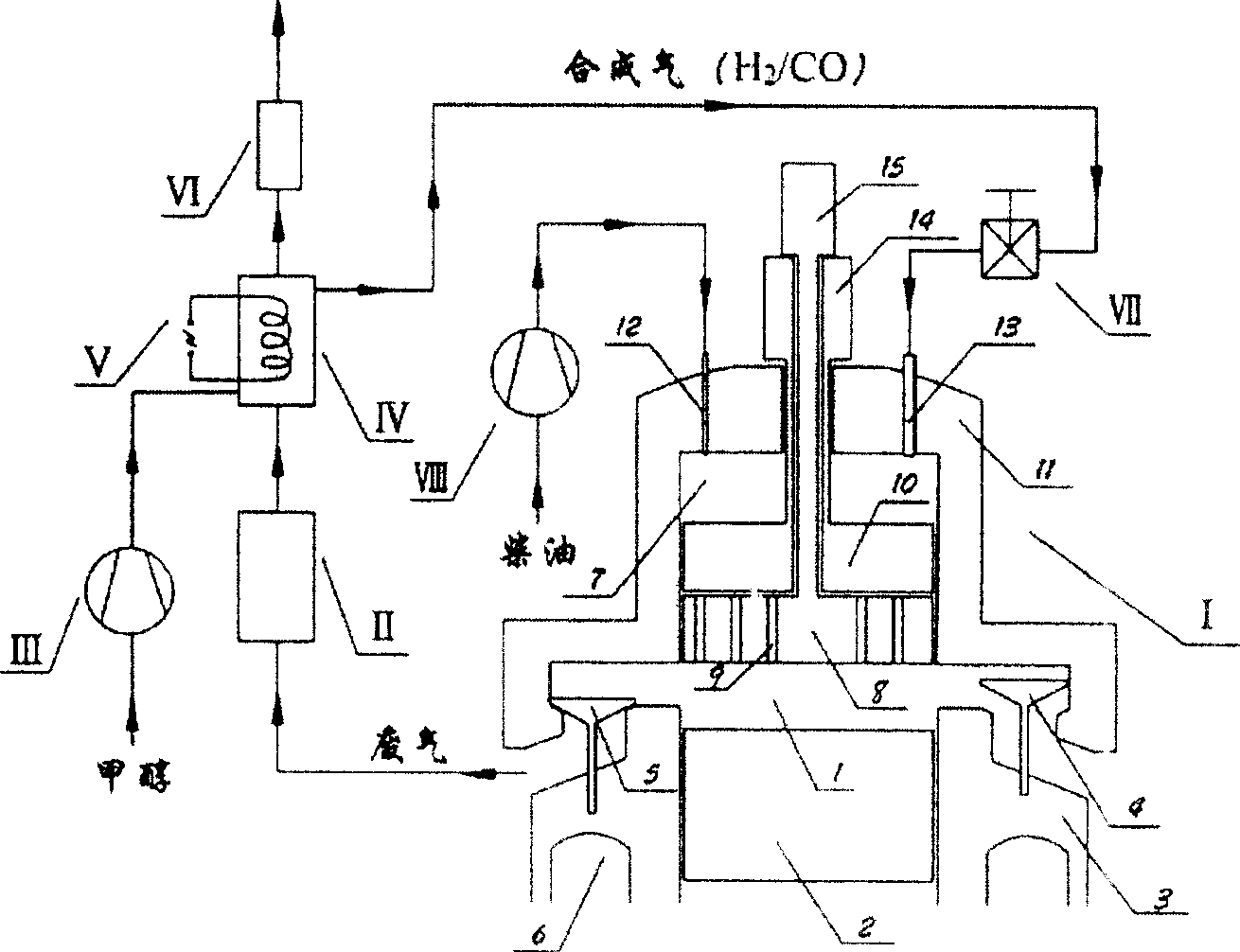

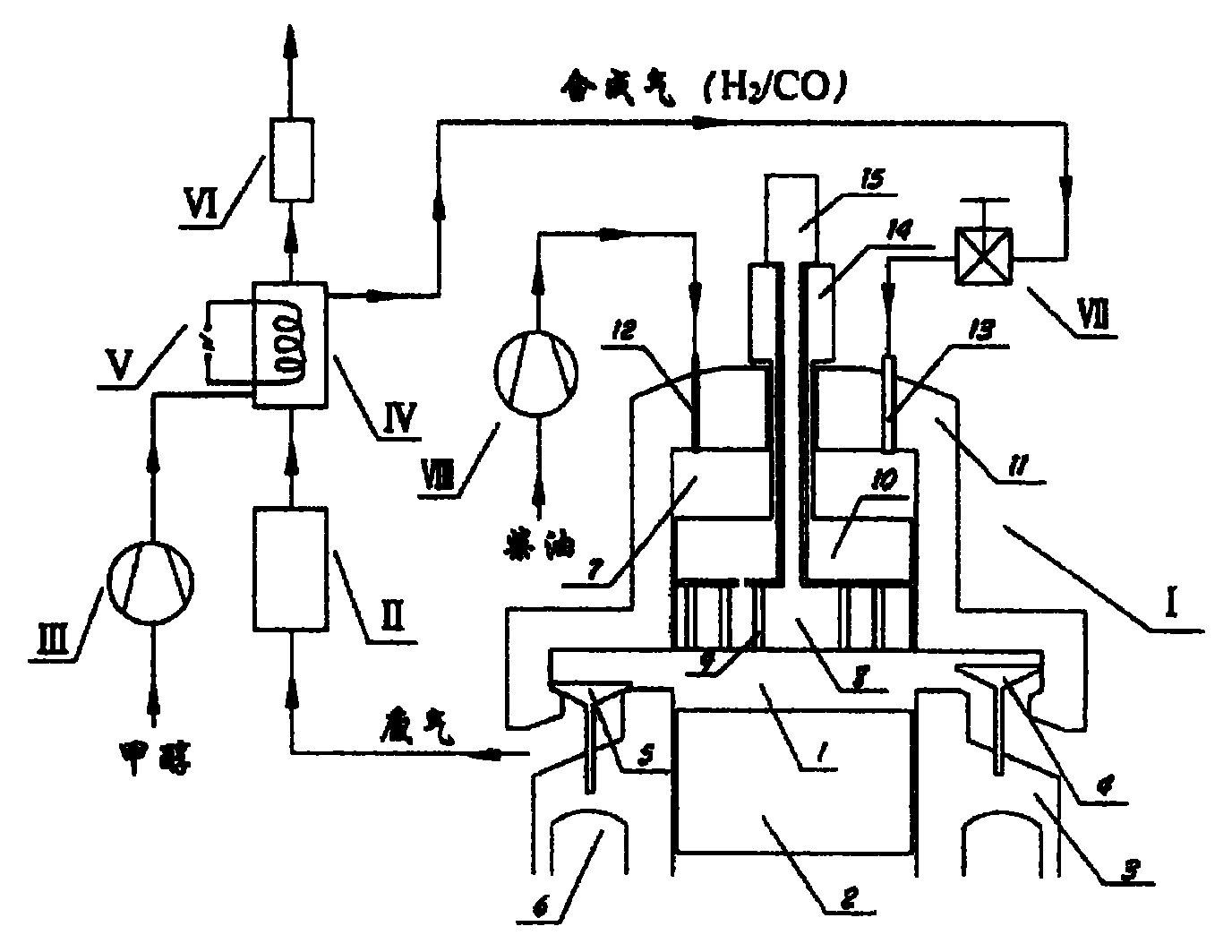

[0035] The invention can better mix the fuel and the air without premixing the fuel and the air, and maintain a relatively stable flame temperature and a high combustion rate under the condition of lean combustion, thereby achieving the purpose of comprehensively reducing exhaust emissions from diesel engines .

[0036] When the diesel engine is working normally, the exhaust temperature can reach about 500°C, and the heat taken away can account for about 30% of the calorific value of the fuel. The present invention utilizes the waste heat of waste gas to catalytically crack methanol to make synthesis gas, the main component of which is H 2 And CO, have a certain temperature (about 400 ~ 500 ℃) and pressure (about 2 ~ 3MPa). Diesel is injected into the synthesis gas at a high pressure at a weight ratio of 5-25:1, and mixed with the synthesis gas, so that most of the diesel is heated and evaporated to form steam or aerosol. Excess air is inhaled according to the air-fuel ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com