Bistable microcomputer electric relay

A relay, bistable technology, applied in the direction of electromagnetic relay, relay, electromagnetic relay detailed information, etc., can solve the difficulty of making high-efficiency coils and permanent magnets, small, generally in the order of microns, the performance and price of micro-electromechanical relays cannot be. To meet market demand and other issues, to achieve high-efficiency symmetrical bistable, short response time, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

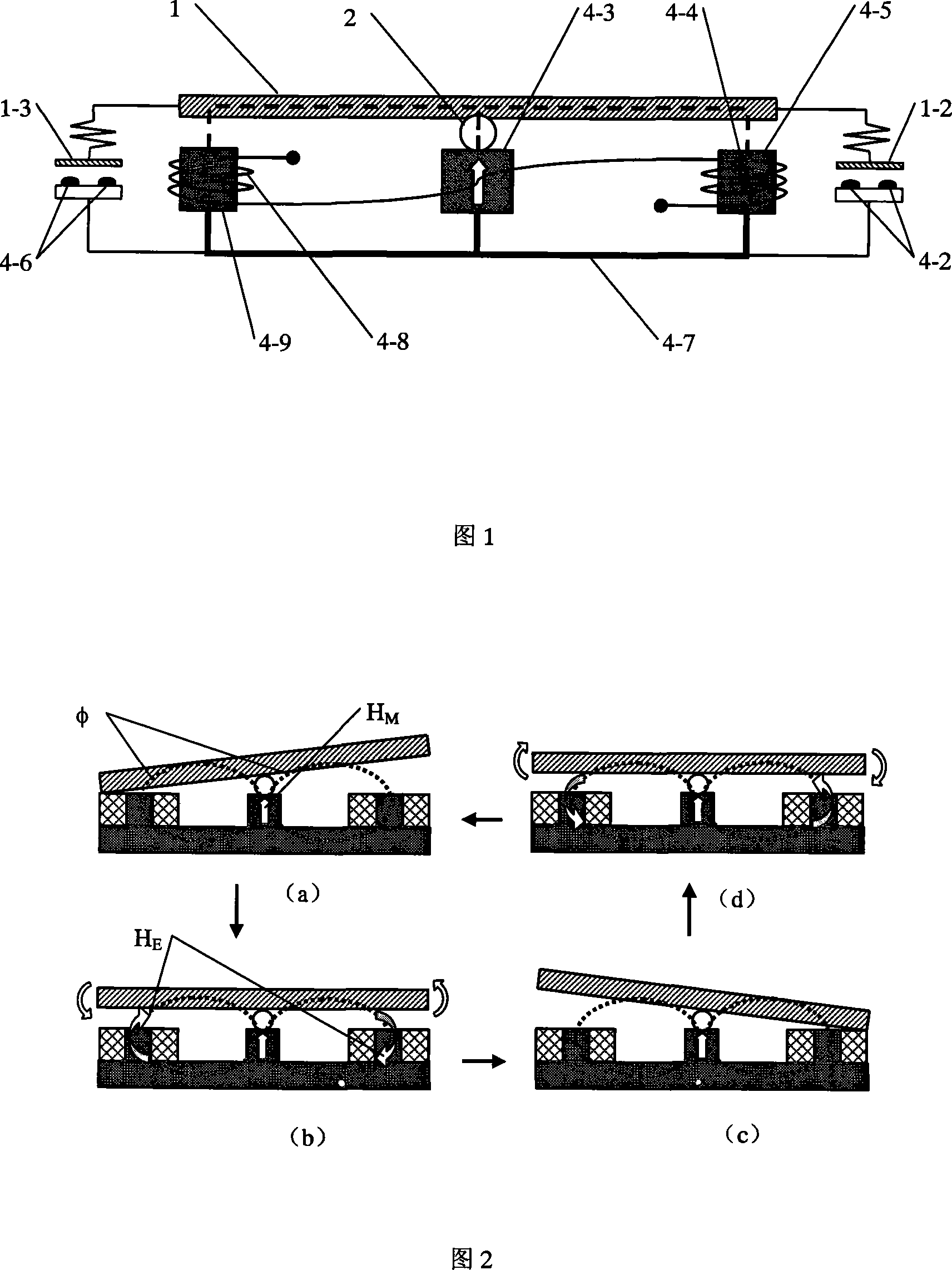

[0065] The four bistable micro-electromechanical relays are described in detail below in conjunction with the accompanying drawings:

[0066] 1. Bistable MEMS relay 1

[0067] Bistable MEMS relays 1 are used for power management and automatic control.

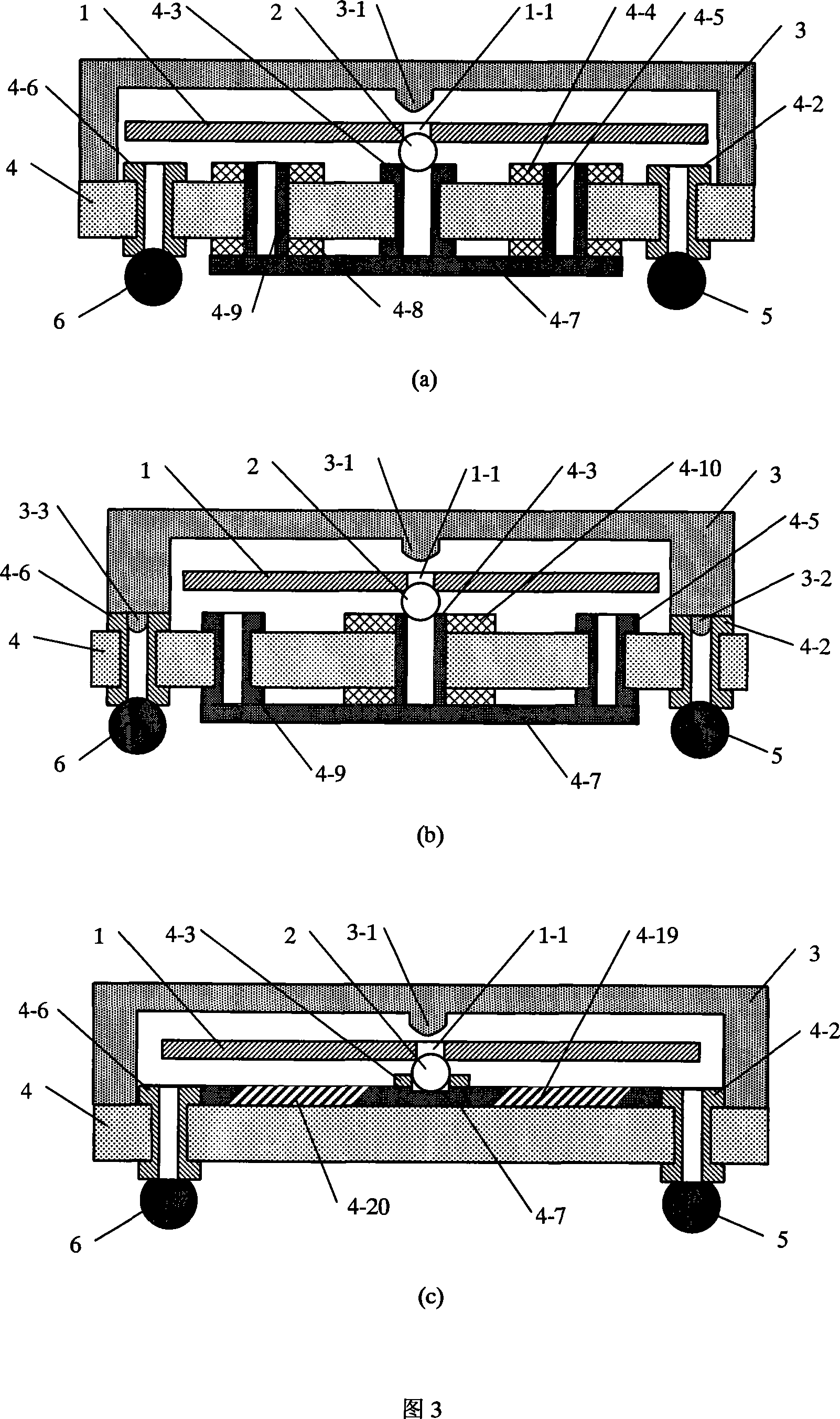

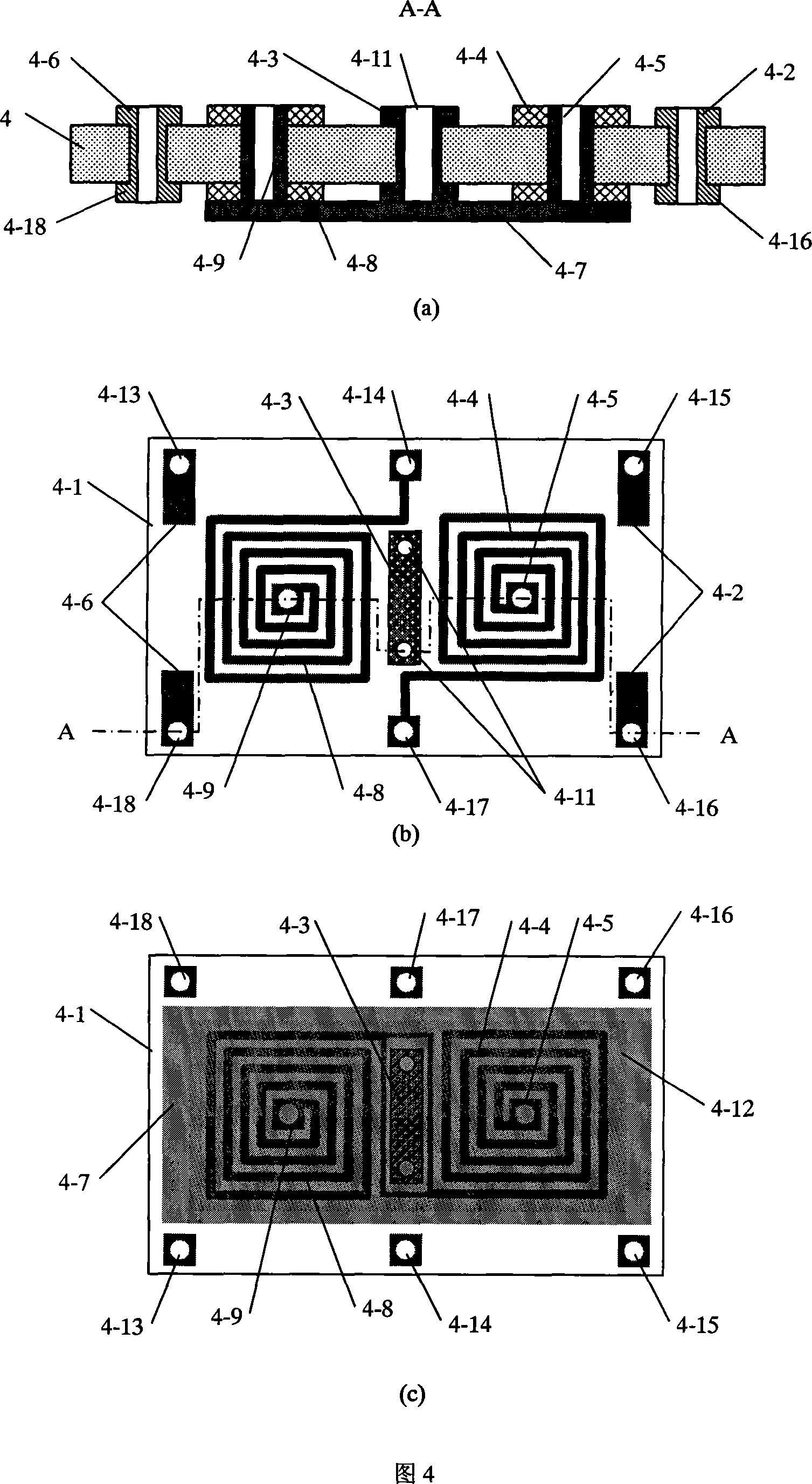

[0068] In Fig. 3 (a), in Fig. 4 (a), (b), (c) and Fig. 5 (a), (b), (c), (d), bistable microelectromechanical relay 1 comprises encapsulation cover 3. Movable diaphragm 1, microsphere 2, electromagnetic substrate 41 and pins.

[0069] In Figure 5(c) and (d), the packaging cover 3 is pressed and sintered by a ceramic material through a mold to grow into a rectangular parallelepiped whose width, width and height are 10mm, 6mm and 0.6mm respectively. Blind holes of 9mm, 4mm, 0.4mm, on the longitudinal axis of the bottom of the package cover 3 opposite to the microsphere 2, there is a ridge 3-1 with a length of 3mm to limit the distance between the movable diaphragm 1 and the microsphere 2 The cross-section of the rib 3-1 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com