Method for monitoring low temperature rapid hot technics

A thermal process and low-temperature technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inability to measure, waste of wafers, and knowing the effectiveness of thermal processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

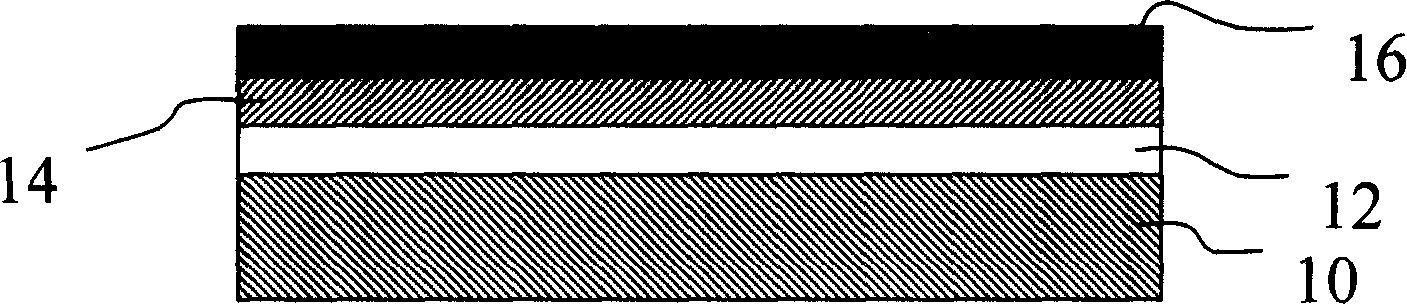

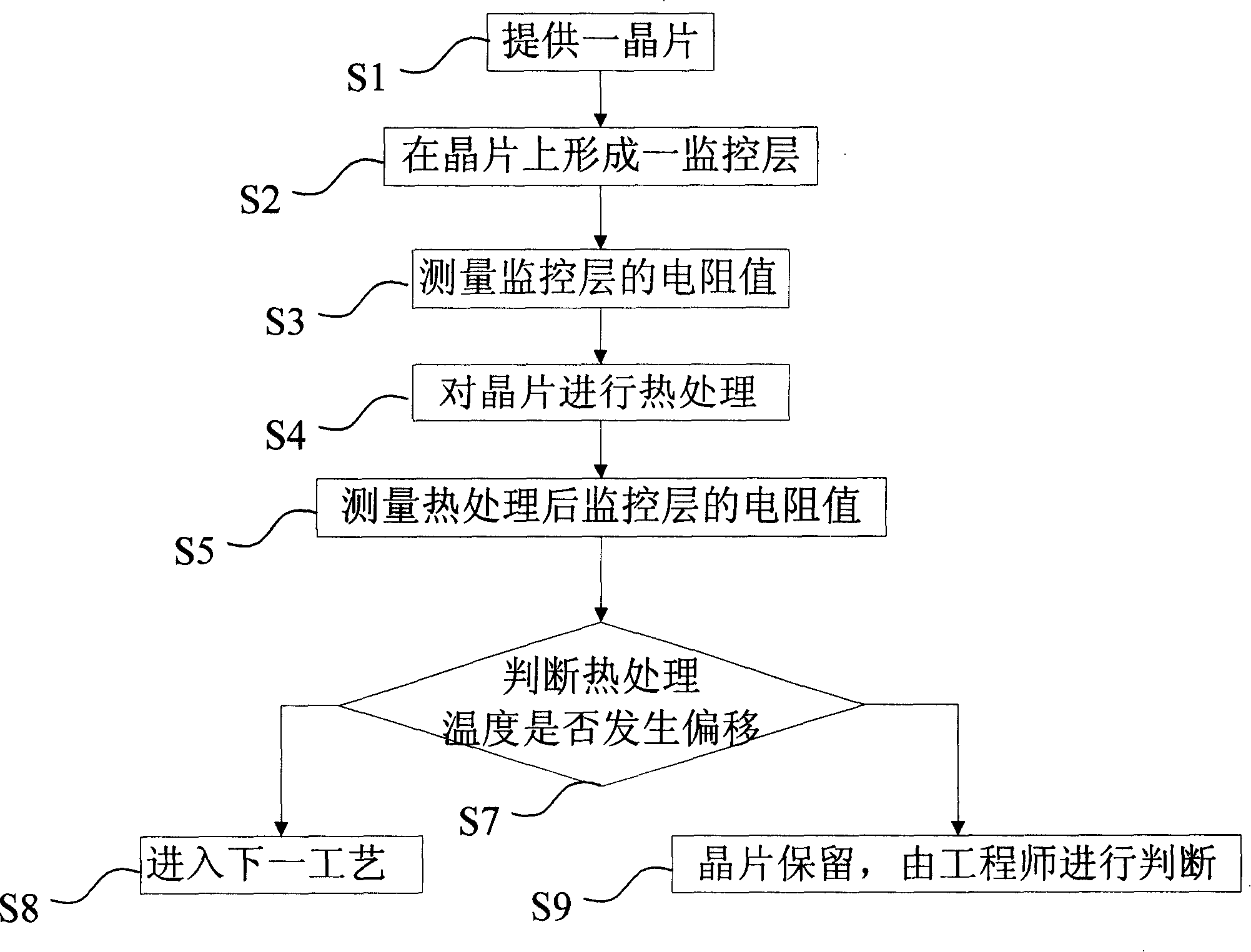

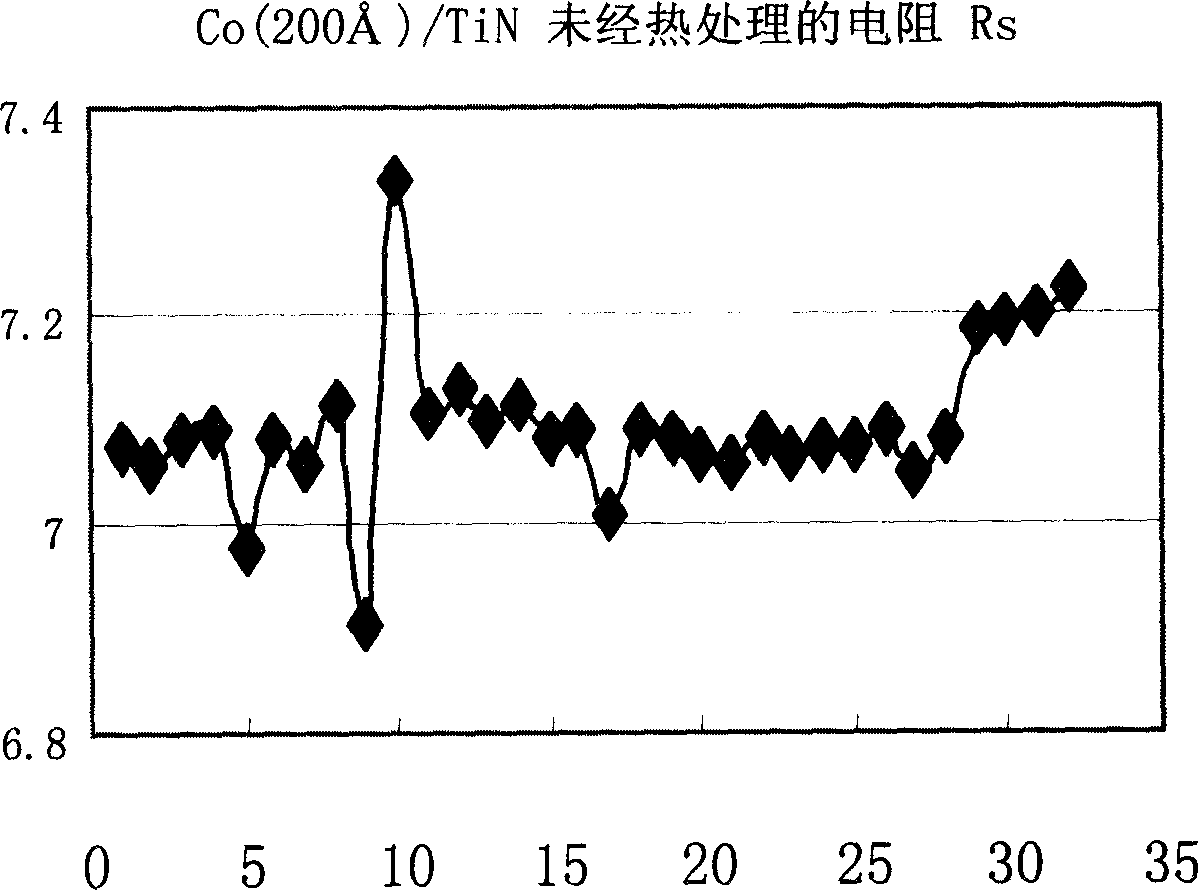

[0022] A method of monitoring low temperature rapid thermal processes, see figure 1 and figure 2 , figure 1 A side view of the wafer after depositing the monitor layer, while figure 2 It is a flow chart of the steps, first as in step S1: a wafer is provided, then as in step S2: a monitoring layer is formed on the wafer 10, the formation method of the monitoring layer is first with low pressure chemical vapor deposition (LPVCD) or with silicon ions or germanium The ions are ion-implanted as dopant ions, and a silicide layer 12 is formed on the wafer 10, wherein the wafer 10 can be a wafer, and then a silicide layer 12 with a thickness of 200 μm is formed on the silicide layer 12. Cobalt metal layer 14, with a thickness of 200 Titanium nitride layer 16, measuring the resistance value of the monitoring layer is as in step S3: judging whether the resistance value is within the upper and lower maximum error range of the monitoring layer resistance value. Of course, this erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com