Inner lining of wafer processing chamber and wafer processing chamber containing said inner lining

A wafer processing and lining technology, which is applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems of limiting the uniformity of the gas flow field on the surface of the wafer, and improve the uniformity of the flow field and increase the airflow passing area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

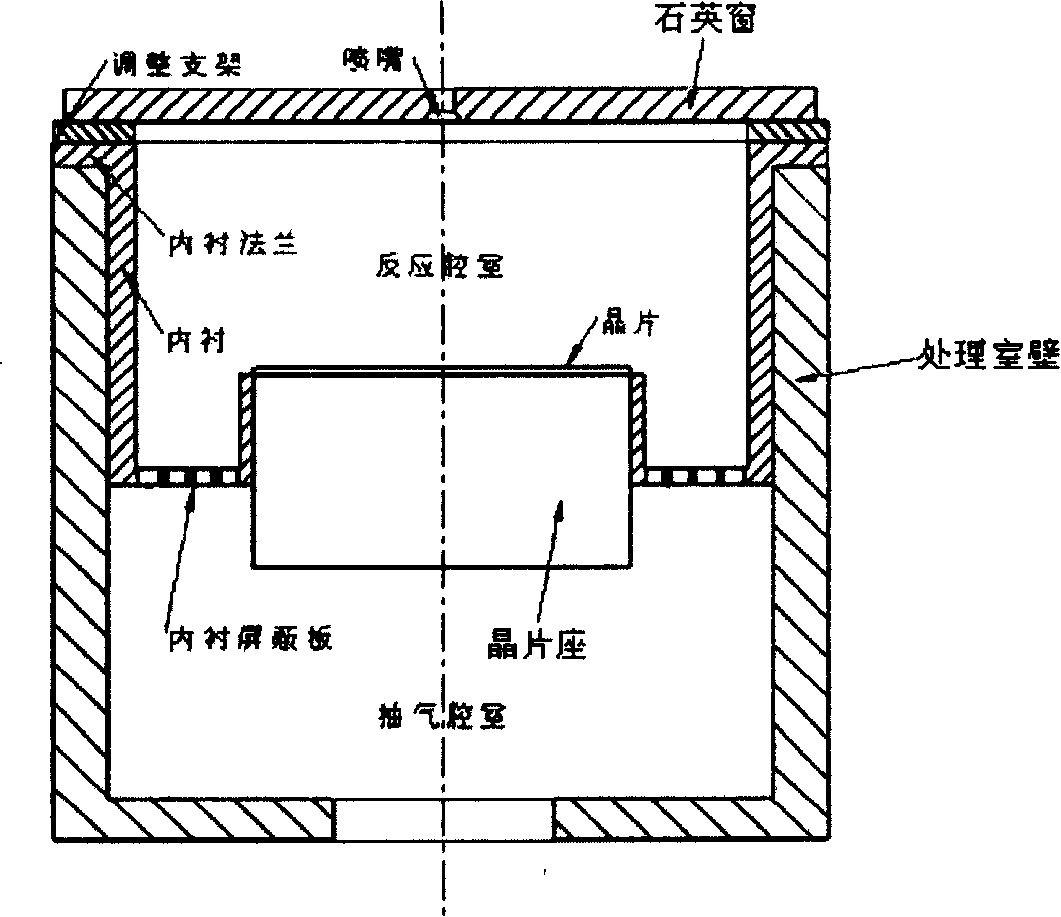

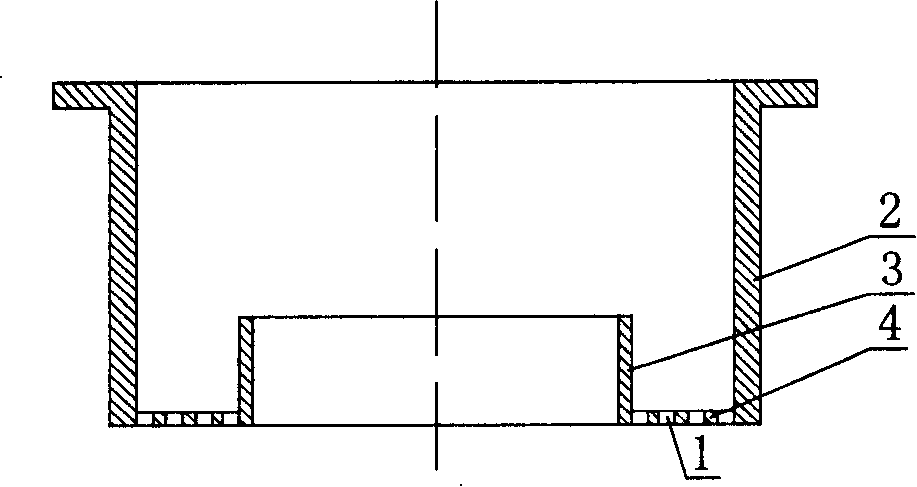

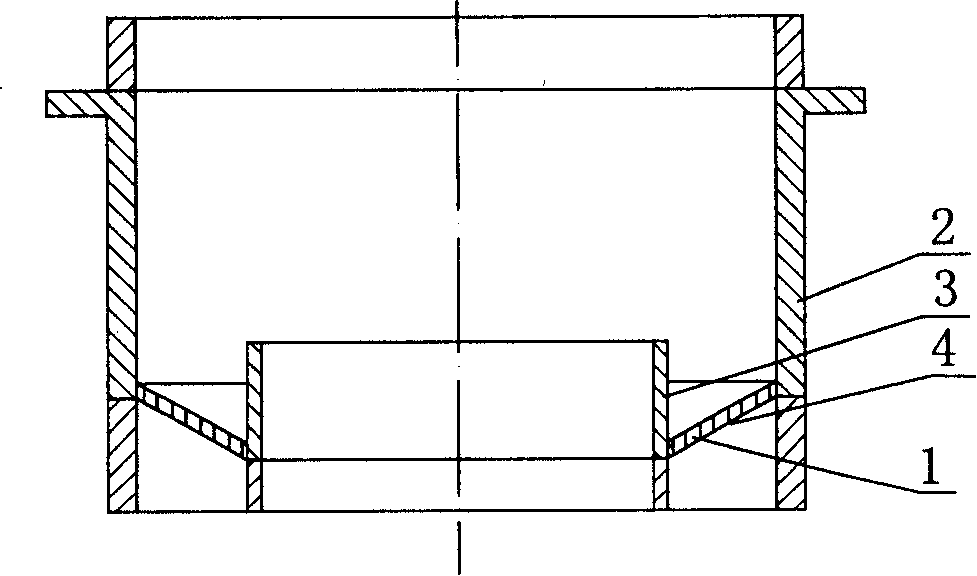

[0022] The lining of the wafer processing chamber of the present invention, its preferred embodiment is as image 3 As shown, it includes an inner side wall 3 and an outer side wall 2, the inner side wall 3 and the outer side wall 2 are connected by a shielding plate 4, and the shielding plate 4 is obliquely connected to the side wall. It may be that the part where the shielding plate 4 is connected to the outer wall 2 is higher than the part where it is connected to the inner wall 3 ;

[0023] The included angle between the shielding plate 4 and the liner axis is 5-80°, preferably 5, 20, 45, 60, 80°, etc., preferably 20-60°.

[0024] The shielding plate 4 is provided with a shielding hole 1 which communicates up and down. The shape of the cross-section of the shielding hole 1 is circular, elliptical or polygonal, or other required shapes.

[0025] The direction of the shielding hole 1 can be parallel to the axis of the lining; it can also be perpendicular to the shielding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com