Gallium oxide-zinc oxide sputtering target, method of forming transparent conductive film and transparent conductive film

A technology of transparent conductive film and gallium oxide, applied in sputtering coating, conductive layer on insulating carrier, circuit, etc., can solve problems such as insufficient countermeasures, effective methods, improvement of sintering density, etc. Achieve the effect of suppressing the volume resistance value to be constant, suppressing the formation of nodules, and preventing the occurrence of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

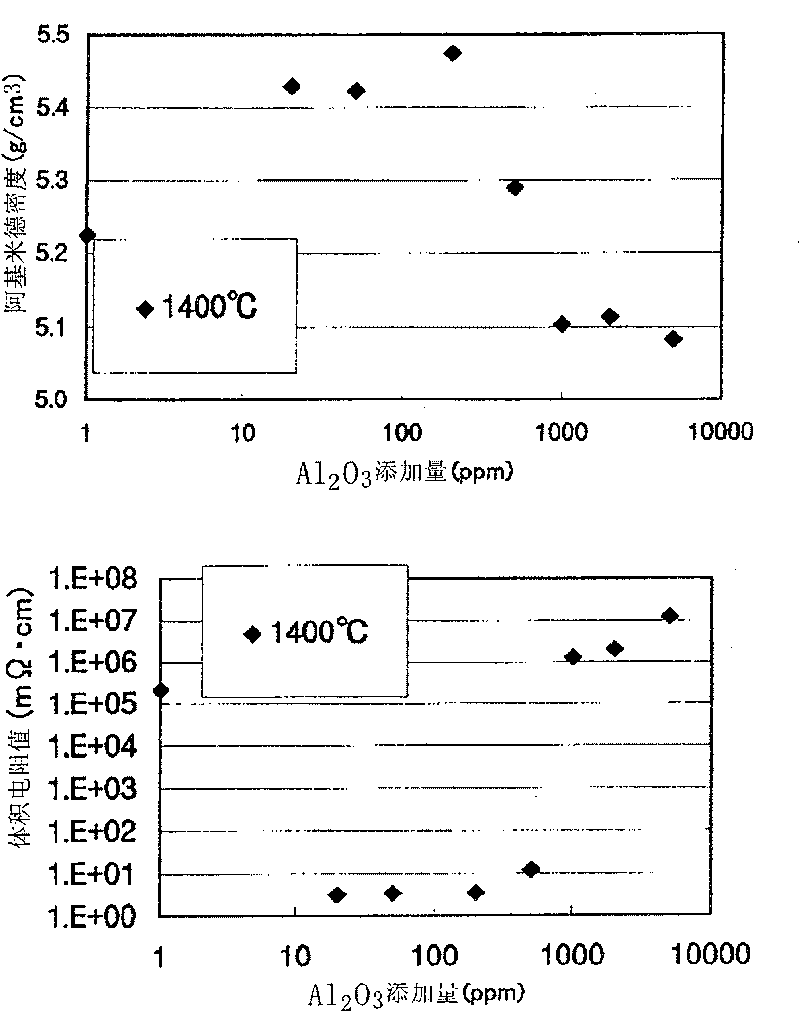

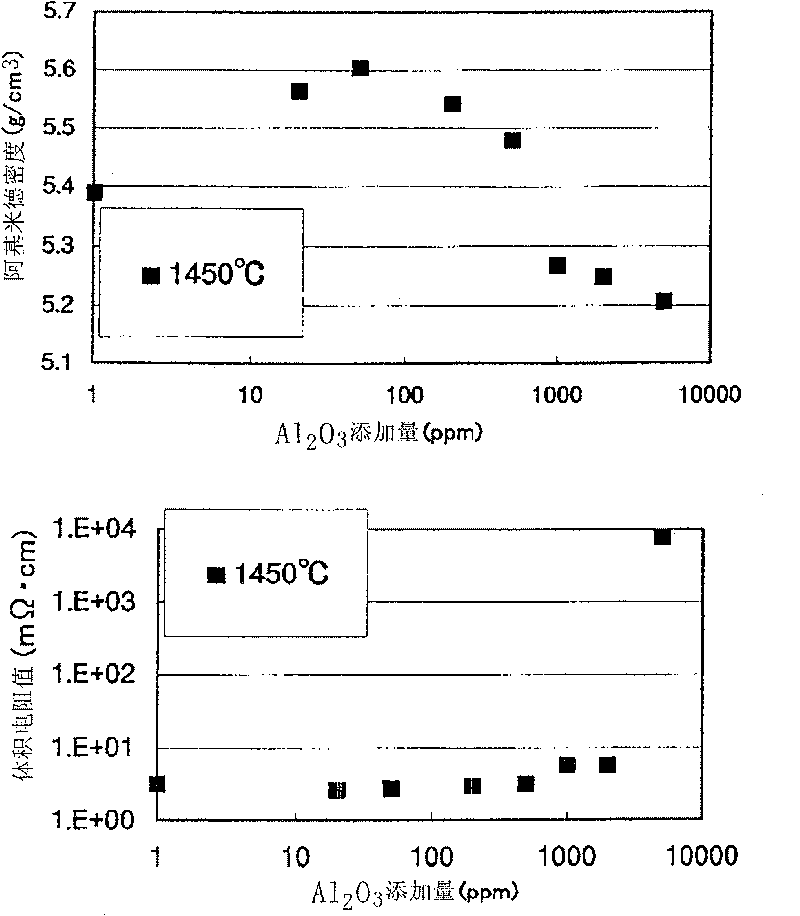

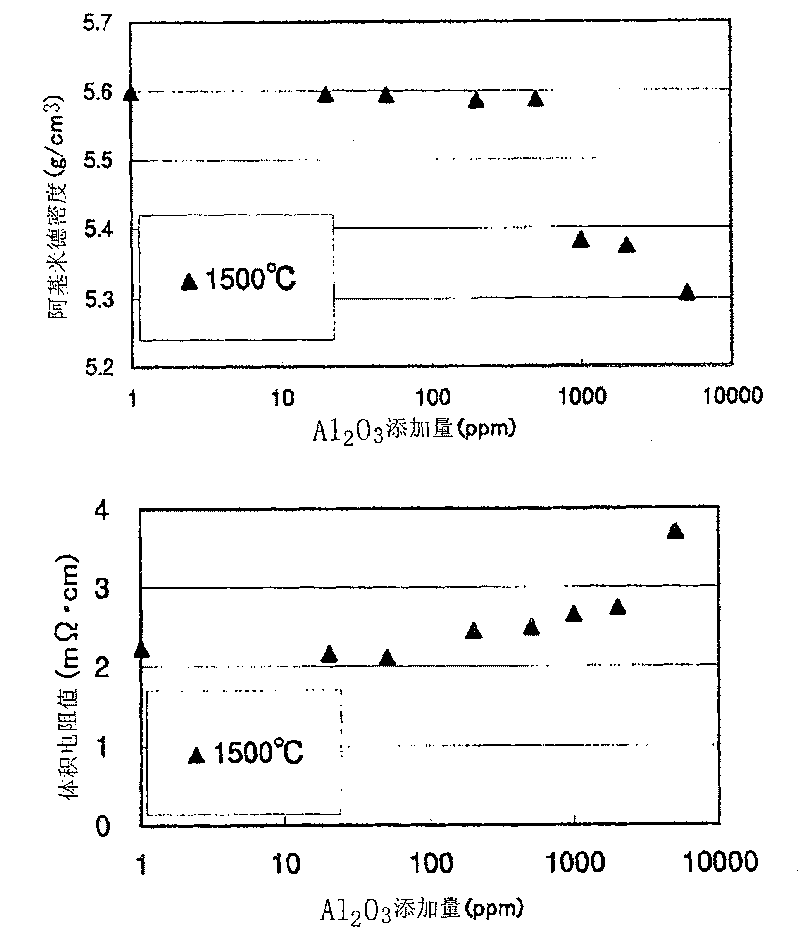

[0064] Weigh Al with an average particle size of 1 μm or less after pulverization by zirconia media 2 o 3 Powder and Ga 2 o 3 powder, zinc oxide (ZnO), to make Al 2 o 3 The powders were 20 mass ppm (Example 1), 50 mass ppm (Example 2), 200 mass ppm (Example 3), 500 mass ppm (Example 4), and Ga 2 o 3 is 5% by mass, and the remainder is ZnO, then, using zirconia (ZrO 2 ) balls or beads as the crushing medium, which are mixed and finely crushed with a dynamic crushing classifier to obtain a mixed powder raw meal with a median pore size of 0.8 μm.

[0065] The raw meal is granulated to obtain a spherical granulated powder. Further, the granulated powder is press-molded, and then CIP (cold isostatic pressing) is performed. Then, the molded body was sintered in an oxygen atmosphere at a temperature of 1500° C. for about 4 hours to obtain a sintered body. This sintered body is ground and cut, and processed into a sputtering target of a predetermined shape.

[0066] Then, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com