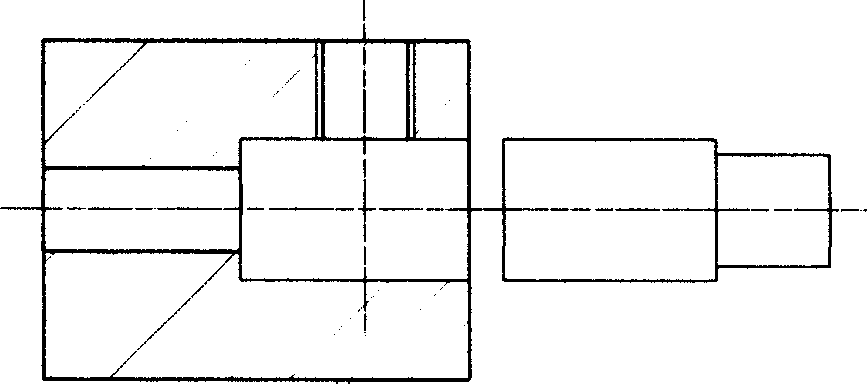

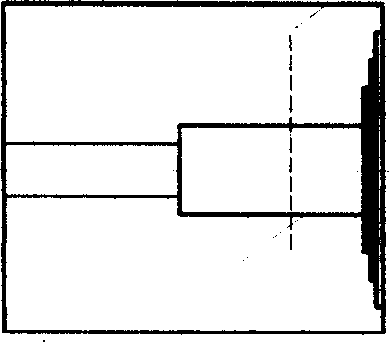

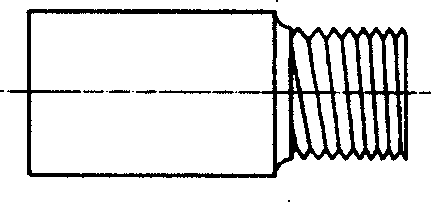

Combination type stirring friction welding tool

A welding tool and friction stir technology, applied in the field of combined friction stir welding tool design, can solve the problems of undesired integral design, scrapped welding tools and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] High-speed steel is used as the tool material, and the shaft shoulder and stirring pin part of the welding tool are respectively processed by turning, milling, drilling and other machining processes, and are heat-treated to a HRC hardness of ~60 for fine grinding and forming. The shaft shoulder and the stirring needle are combined through a precise sliding assembly, and the assembly tolerance is 0.01mm. The precise positioning and fastening of the stirring needle is realized through the design of the boss inside the shaft shoulder and the fastening screw. Such a combined welding tool can be widely used for welding aluminum, magnesium, copper alloys and composite materials thereof. When the stirring needle is broken or severely worn, take out the damaged stirring needle and replace it with a new stirring needle to restore the use function of the welding tool.

Embodiment 2

[0027] High-speed steel and high-temperature alloy are used as raw materials, and high-speed steel shoulders and high-temperature alloy stirring pins are processed by machining processes such as turning, milling, and drilling. Carry out fine grinding and shaping. The assembly of the shaft shoulder and the stirring needle is realized by threads, and the positioning and fastening of the stirring needle are realized by screws. Such combined welding tools are mainly used for welding copper alloys and other high melting point metal materials. When the high-temperature alloy stirring needle is broken or severely worn, take out the damaged stirring needle and replace it with a new stirring needle to restore the use function of the welding tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com