Automatic arranging device for arrangement steel nails

An automatic, row-by-row technology, applied in packaging, transportation and packaging, conveyor objects, etc., can solve the problems of steel row nails that cannot be automated production, steel nails that are easy to agglomerate and difficult to arrange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

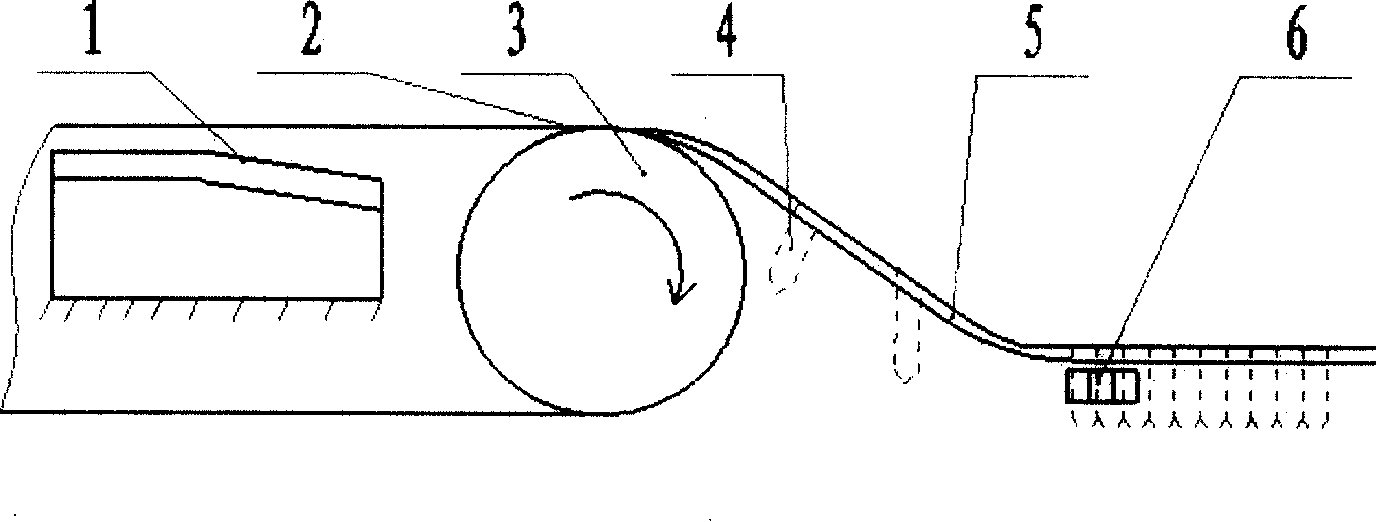

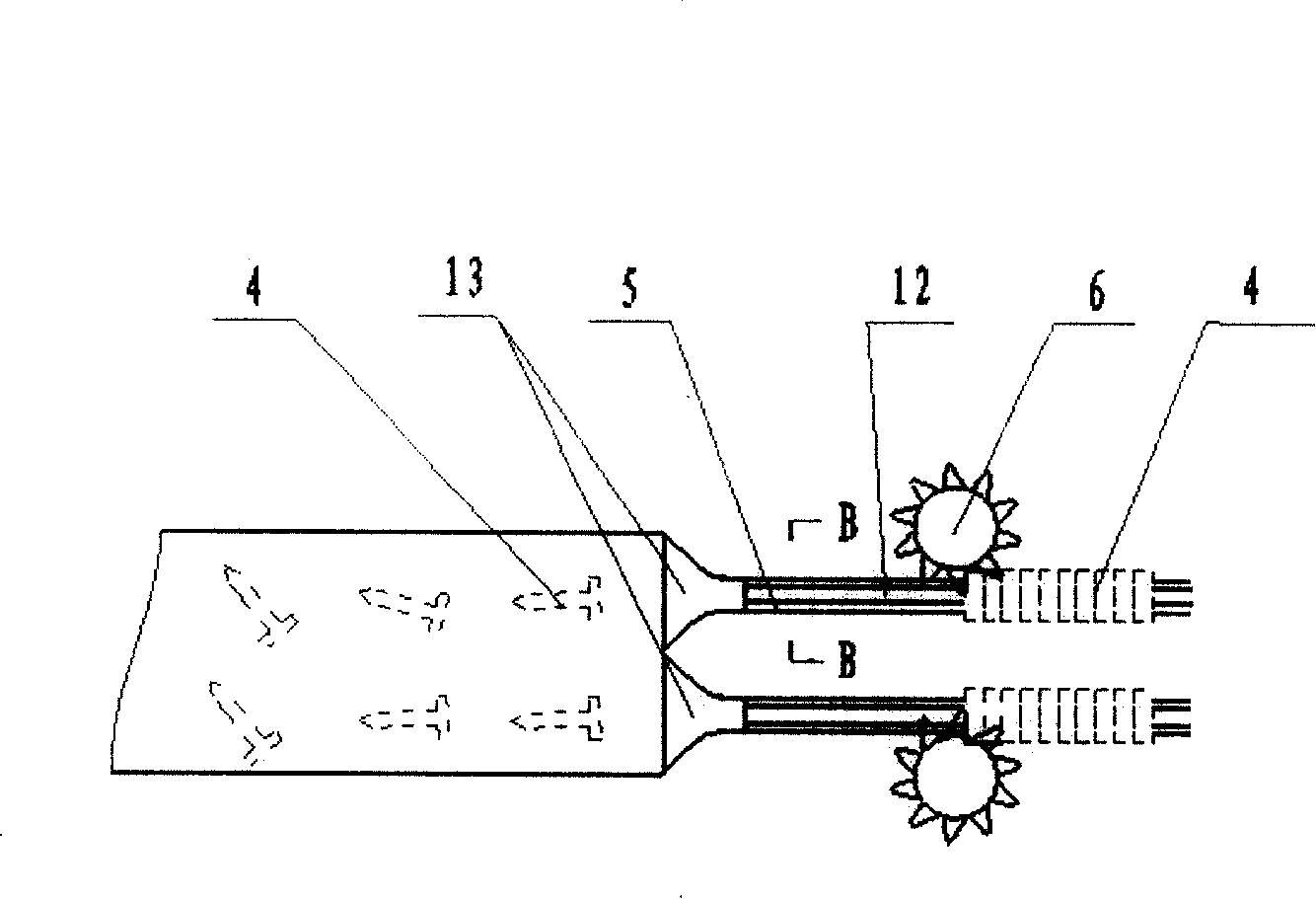

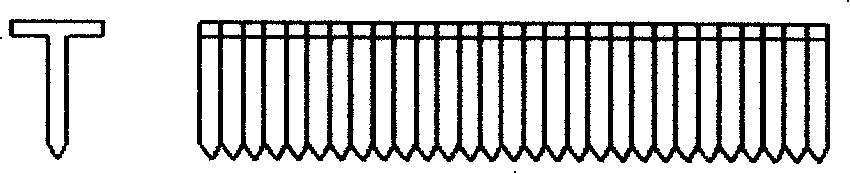

[0021] Such as figure 1 , 2 As shown, the automatic nail arranging device of this steel includes a strip magnet 1, a pulley 3 and a conveyor belt 2 installed on the pulley 3. The strip magnet 1 is located below the conveyor belt 2 and is attached to the inside of the upper surface of the conveyor belt 2. Shaped magnetic steel 1 upper surface is combined by straight plane and inclined plane, and straight plane is level, and inclined plane is high in front and low in back. Two rows of slideways 5 are arranged side by side at the rear of the conveyor belt 2, and a collecting bucket 13 is arranged at the head of the two rows of slideways 5 to be tangent to the end of the conveyor belt 2. The rear part is placed horizontally, and a ratchet 6 is respectively established on the side of the horizontal part. Such as Figure 4 Shown, slideway 5 bottom surface has the slit 12 that is bigger than steel nail diameter less than steel nail cap width size, and the ratchet 6 that is positi...

Embodiment 2

[0024] Such as Figure 5 , 6 As shown, the automatic nail arranging device of this steel includes a strip magnet 1, a pulley 3 and a conveyor belt 2 installed on the pulley 3. The strip magnet 1 is located below the conveyor belt 2 and is attached to the inside of the upper surface of the conveyor belt 2. The upper surface of shaped magnetic steel 1 is composed of a straight plane and an inclined plane, the straight plane is horizontal, and the inclined plane is high at the front and low at the rear. The end of the conveyor belt 2 is horizontally connected with a slideway 5, and the end of the slideway 5 turns horizontally to 90 degrees to form a corner slideway 11. The rear corner side of the slideway 5 is provided with an eccentric wheel 7 and a push rod 10, and the push rod 10 is covered Back-moving spring 8 is arranged, and spring 8 is supported on the baffle plate 9 of corner slideway 11 sides, and push rod 10 is perpendicular to slideway 5, is parallel to corner slidewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com