Construction method for column and architrave cornice

A construction method and pillar technology, which are applied in the field of pillar and forehead cornice construction, can solve the problems of inconvenient transportation, high construction cost, and high manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

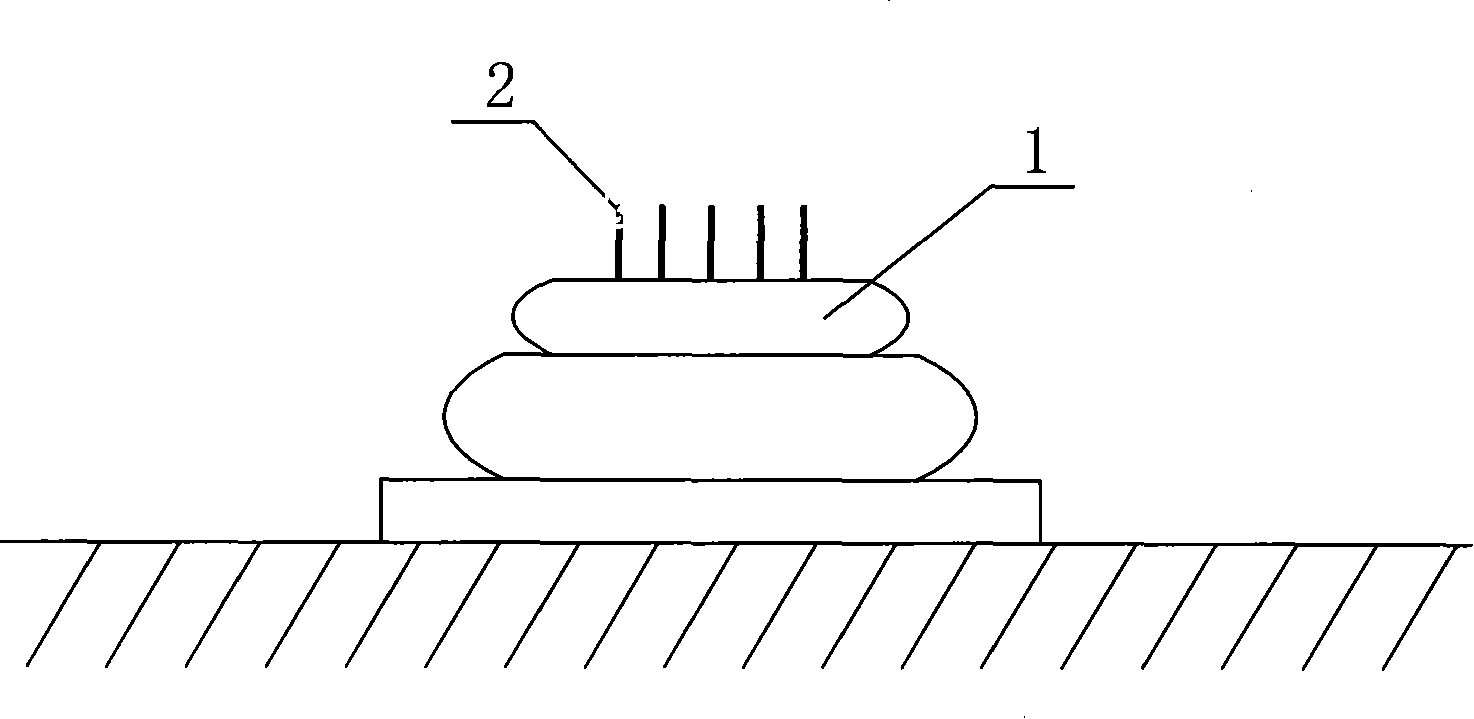

[0019] Such as Figure 1 ~ Figure 5 As shown, a method for constructing columns and forehead cornices includes the following steps in sequence:

[0020] A. Pouring the column pier 1 on site, and reserve multiple anchoring steel bars 2 on the top of the column pier;

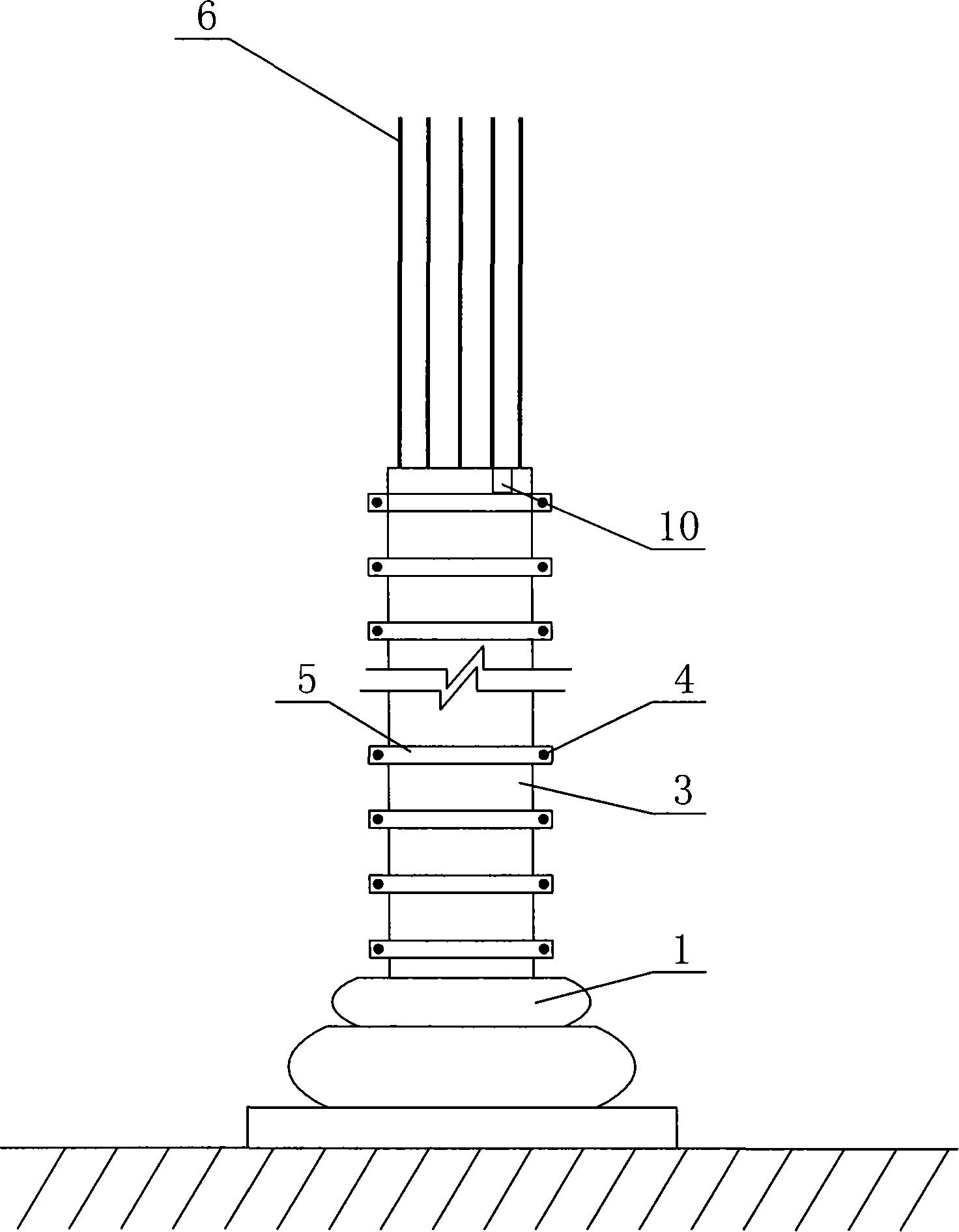

[0021] B. Reinforcing steel bars, extending the connecting rebar 6 on the anchoring steel bars of the column piers up to the installation height of the cornice of the forehead;

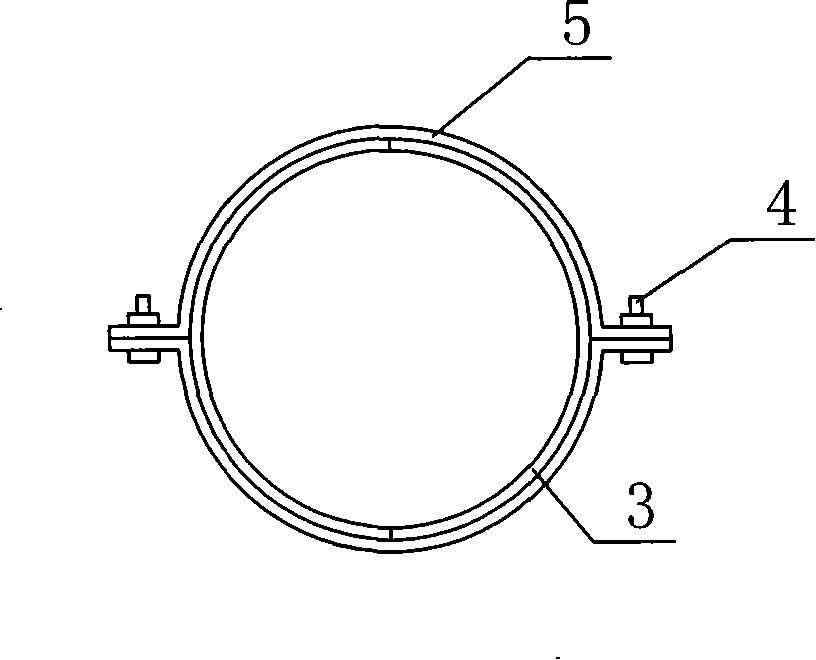

[0022] C. Install the column mold 3, install the column mold for pouring the column body on the pillar pier, and fasten a flat iron ring 5 evenly at intervals of 30 cm along the length of the column mold; see figure 2 The flat iron ring shown is formed by splicing two semi-circular parts through bolts 4, and is fastened and sleeved on the outside of the pillar mold, and the pouring port 10 is located on the top side of the pillar mold;

[0023] D. Install the column head 8, build the bracket 7 and place the prefabricated column head suspended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com