Tamping-proof monitoring device for drilling platform turntable surface of drilling machine used for petroleum exploration

A technology of oil exploration and monitoring equipment, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of the big hook hitting the turntable surface of the drill floor and the turntable, etc., so as to reduce the hidden danger of accidents , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] As shown in Figure 1, it is a structural block diagram of a monitoring device for anti-smashing of the rig floor turntable surface of a drilling rig for oil exploration, and the described monitoring device for anti-smashing of the rig floor turntable surface of a drilling rig for oil exploration It consists of a photoelectric encoder sensor 1, an anti-smashing controller 2, and a hydraulic control proportional valve 3. The photoelectric encoder sensor 1 is connected to the hydraulic control proportional valve 3 through the anti-smashing controller 2.

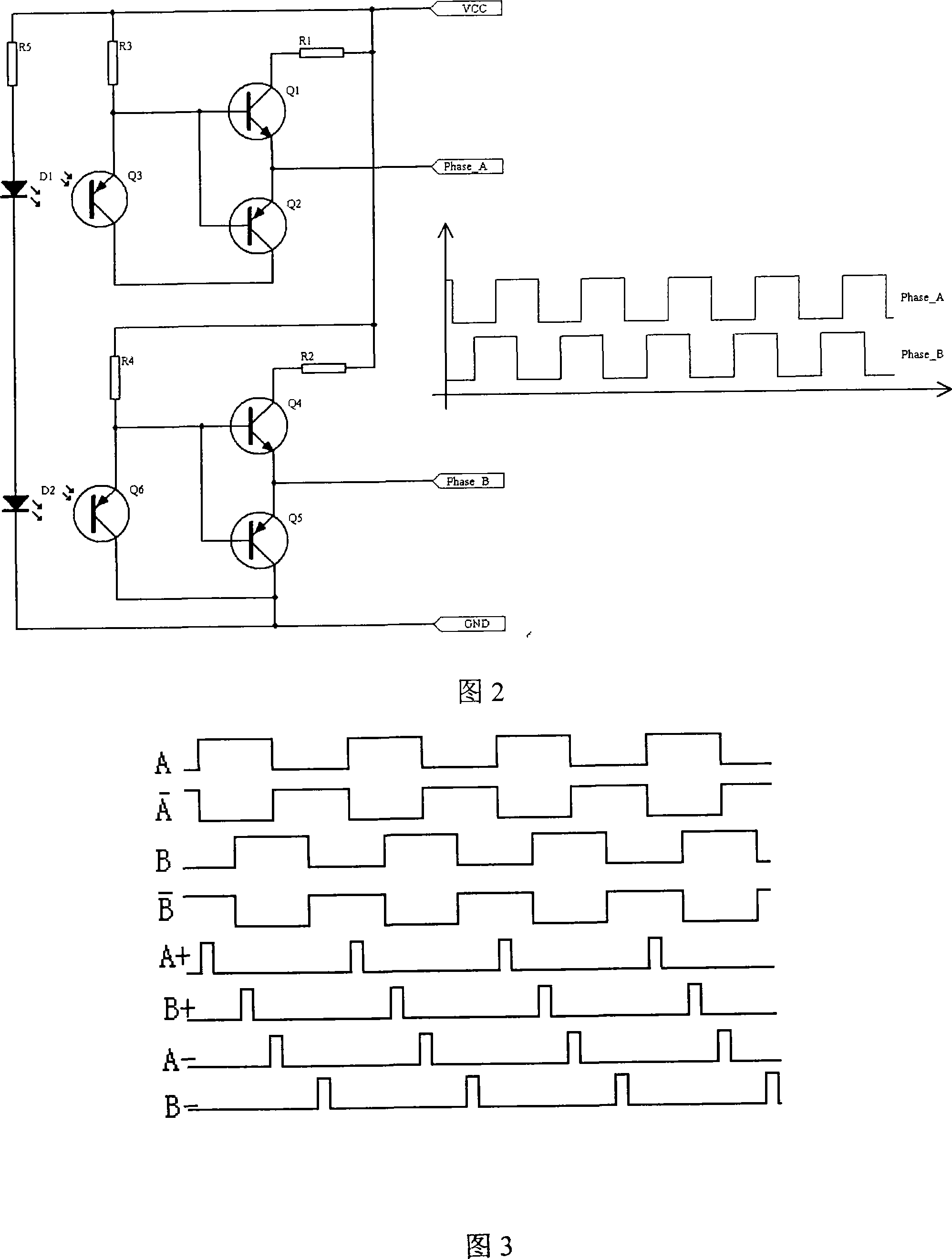

[0016] As shown in Figure 2, it is a schematic diagram of a photoelectric encoder sensor. The photoelectric encoder sensor 1 is composed of 6 triodes Q1-Q6, 2 diodes D1-D2, and 5 resistors R1-R5. The collector of the triode Q1 Connect to the power supply through the resistor R1, the base of the transistor Q1 is connected to the base of the transistor Q2, and connected to the emitter of the resistor R3 and the transistor Q3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com