Lens module group and its assembling method

A lens module and assembly method technology, applied in the field of photography, can solve the problems such as the inability to effectively improve the assembly yield and the inability to reduce the manufacturing cost of the lens module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

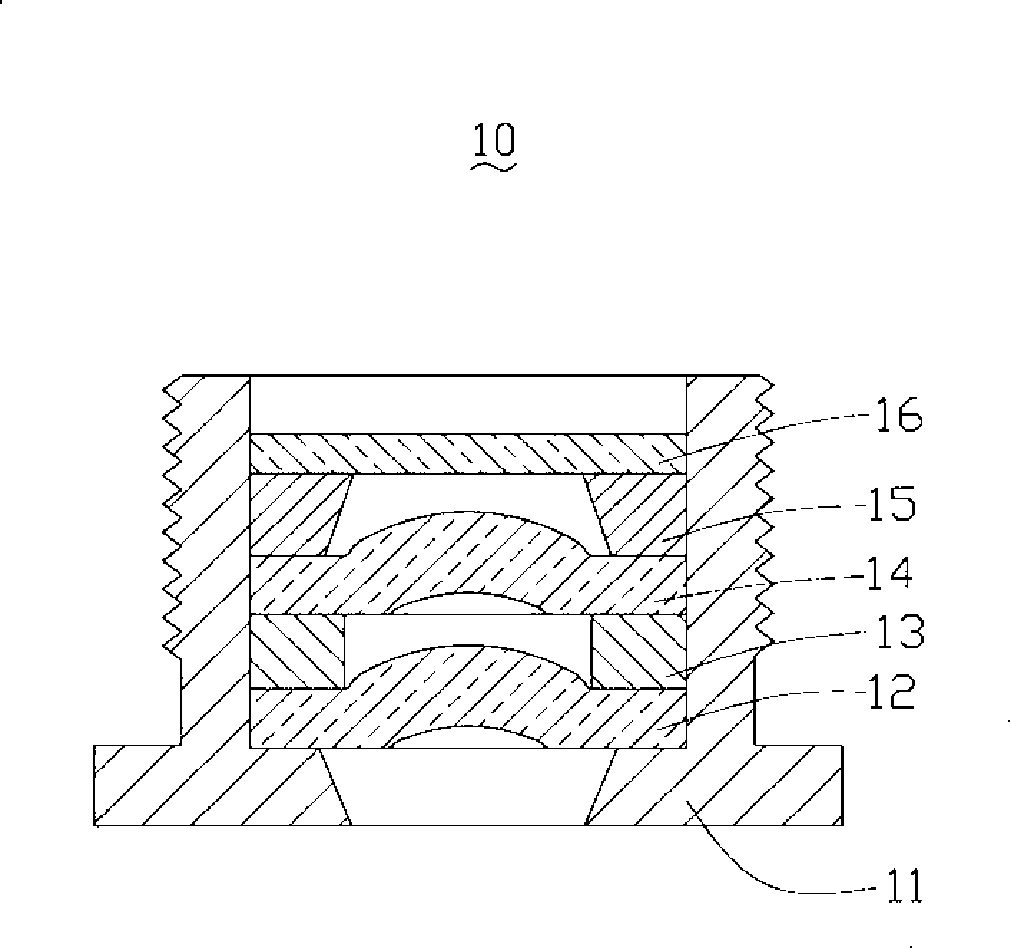

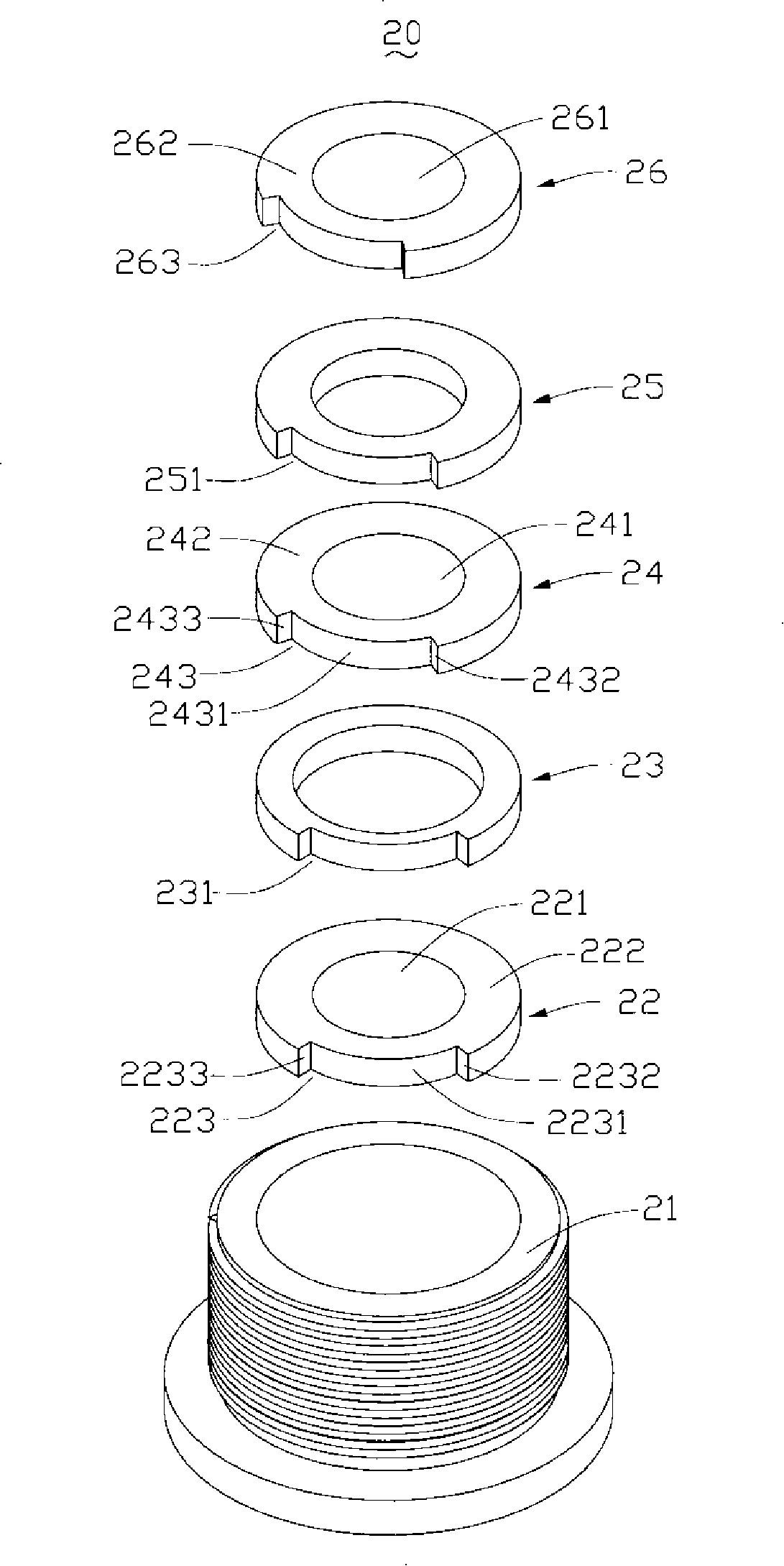

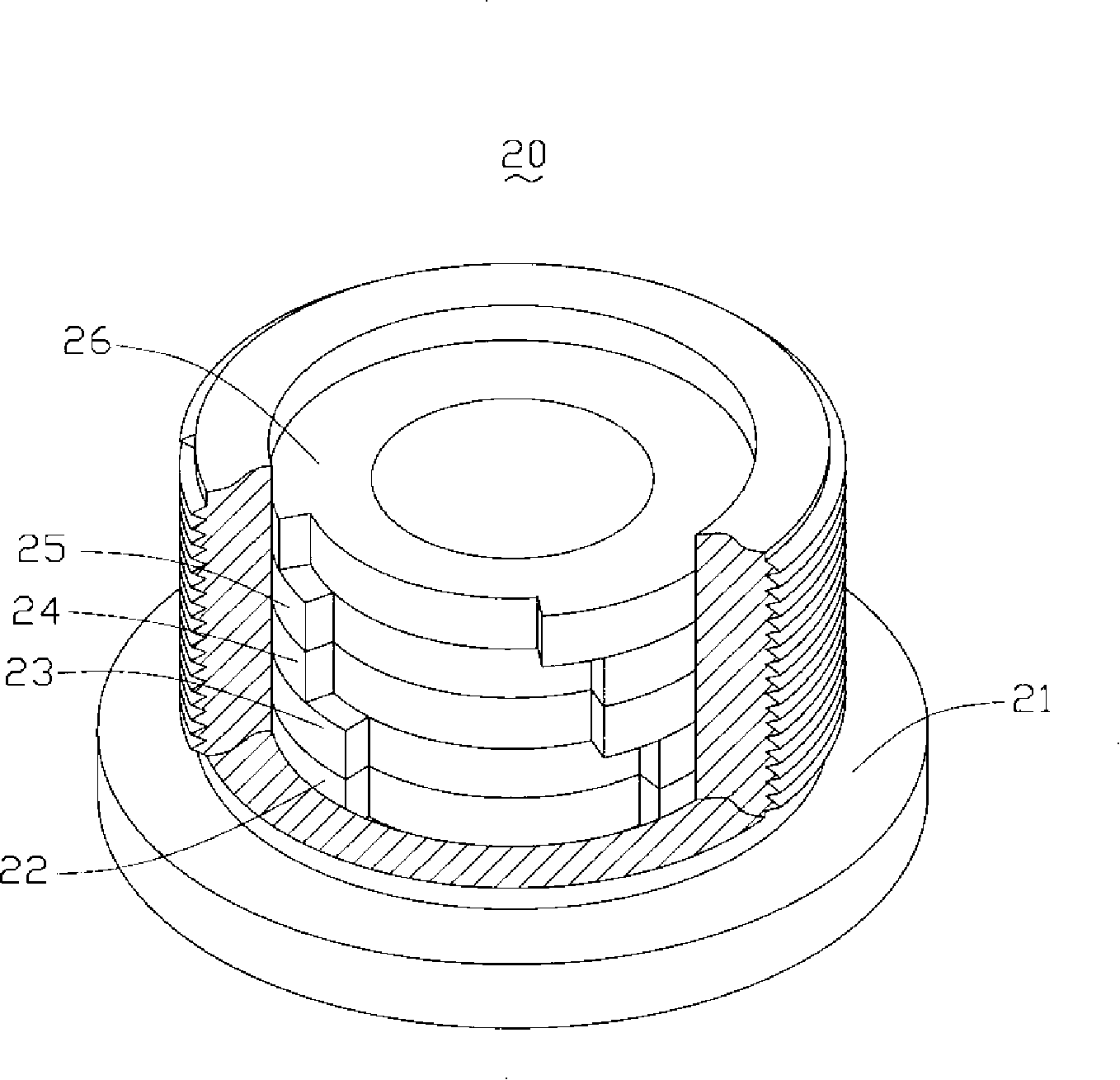

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] see figure 2 and image 3 , a kind of lens module 20 that the first embodiment of the present invention provides, it comprises a lens barrel 21 and along the object side direction of lens barrel 21 is arranged in sequence in the lens barrel 21 first lens 22, aperture plate 23, the first The second lens 24 , the spacer ring 25 and the third lens 26 .

[0014] The first lens 22 has an optical portion 221 located at its center and a non-optical portion 222 located on the periphery of the optical portion 221, the non-optical portion 222 has a notch 223, and the notch 223 is formed by one side facing the first The front surface 2231 in the radial direction of the lens 22 is surrounded by two side surfaces 2232 , 2233 facing the circumferential direction of the first lens 22 . The second lens 24 and the third lens 26 have a structure similar to that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com