Organic electroluminescent display device and method of manufacture

An electroluminescence display and display device technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, electrical components, etc., can solve problems such as energy level mismatch between RGB three colors, affecting device performance, etc., and achieve high yield , The effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

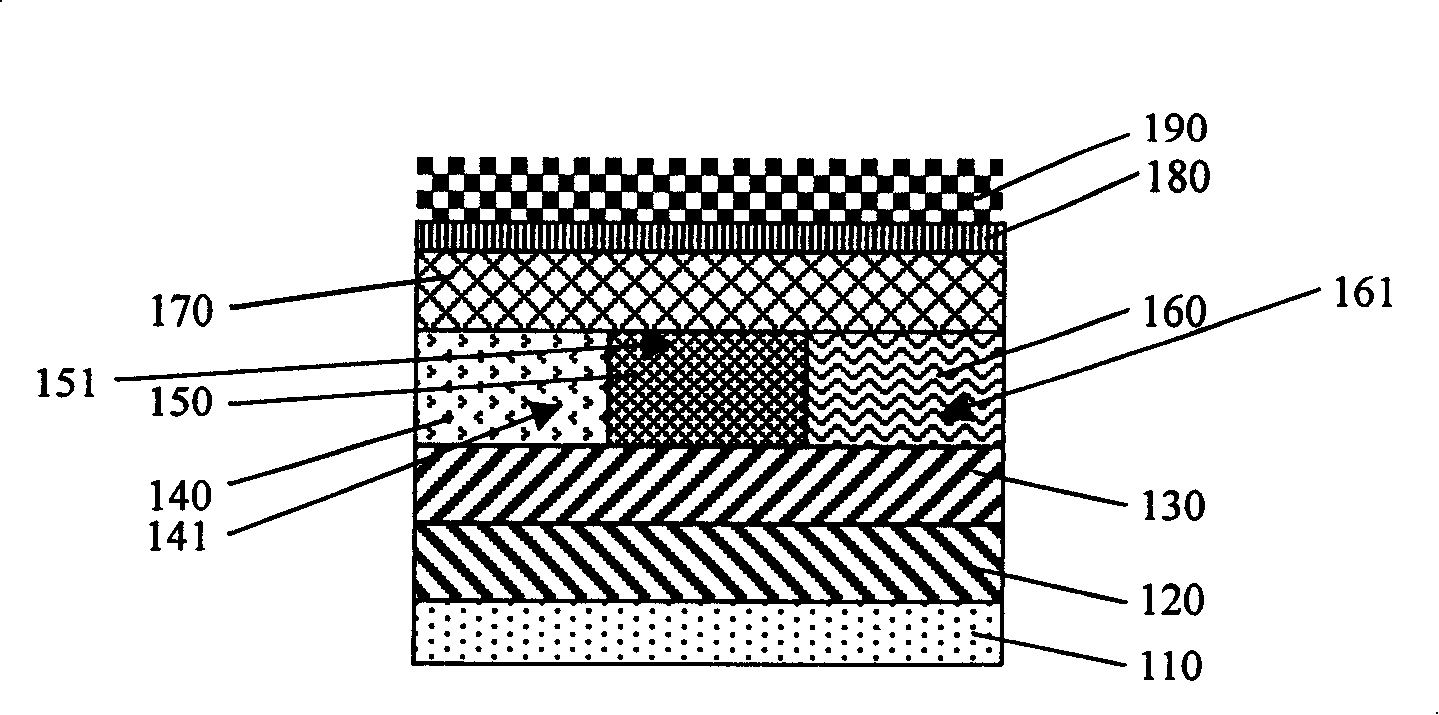

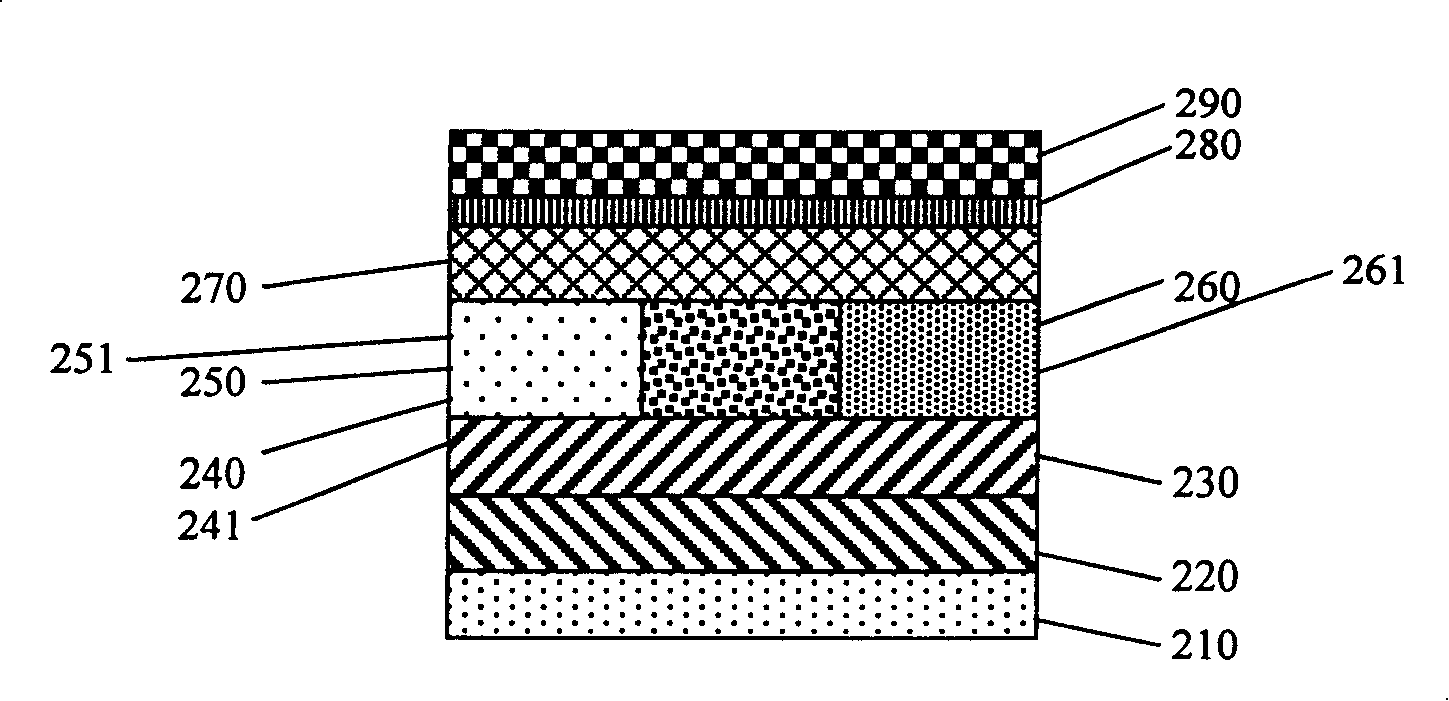

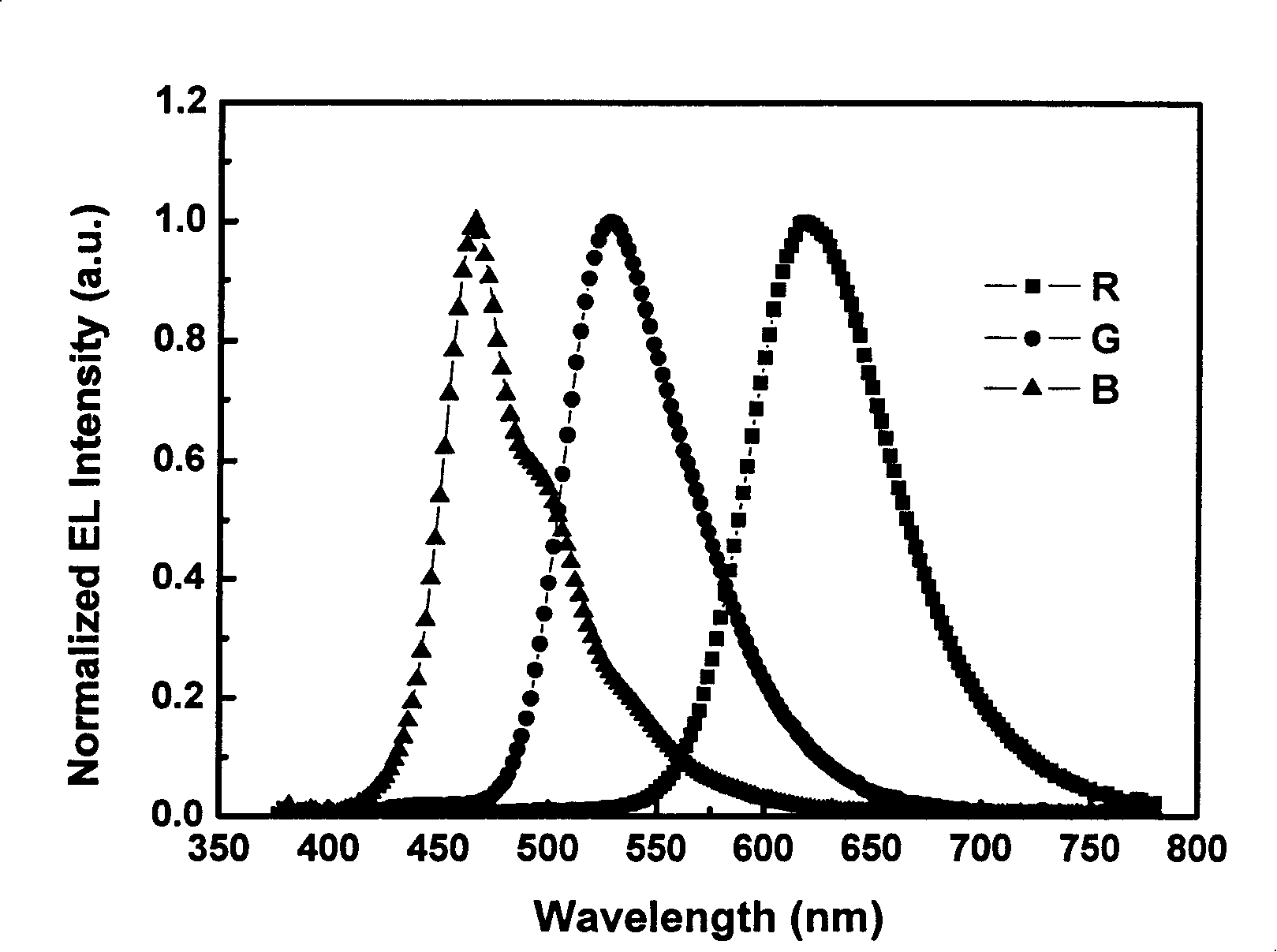

[0025] see figure 2 As shown, an organic electroluminescent display device provided by the embodiment of the present invention includes a cathode layer 290 from top to bottom, an electronic organic functional layer including an electron injection layer 280 and an electron transport layer 270, and RGB three-color luminescence layer, a hole organic functional layer comprising a hole transport layer 230 and a hole injection layer 220, and an anode layer 210; it is characterized in that the light-emitting layer adopts the same wide-level light-emitting host (host) material, ( There are at least two layers containing the same host...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com