An organic thin film transistor and its making method

An organic thin film and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of reduced component performance characteristics, poor adhesion, etc., to improve component performance, save costs, avoid The effect of component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

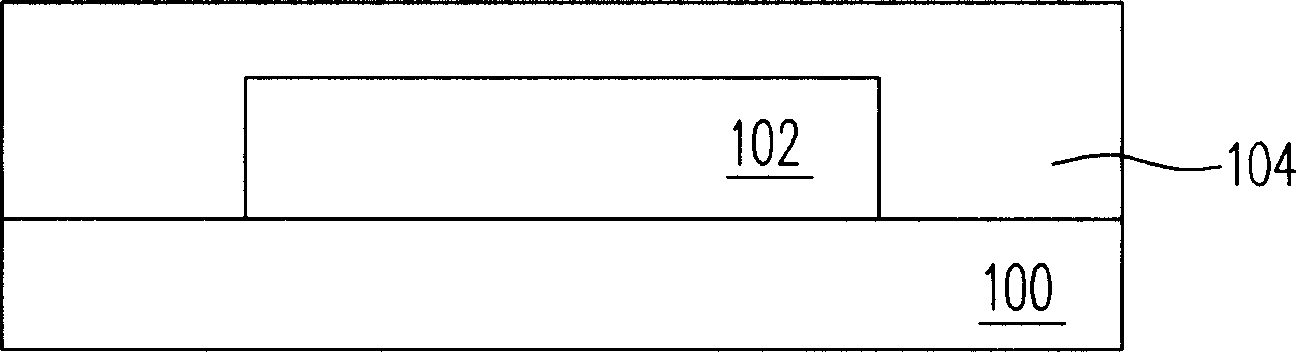

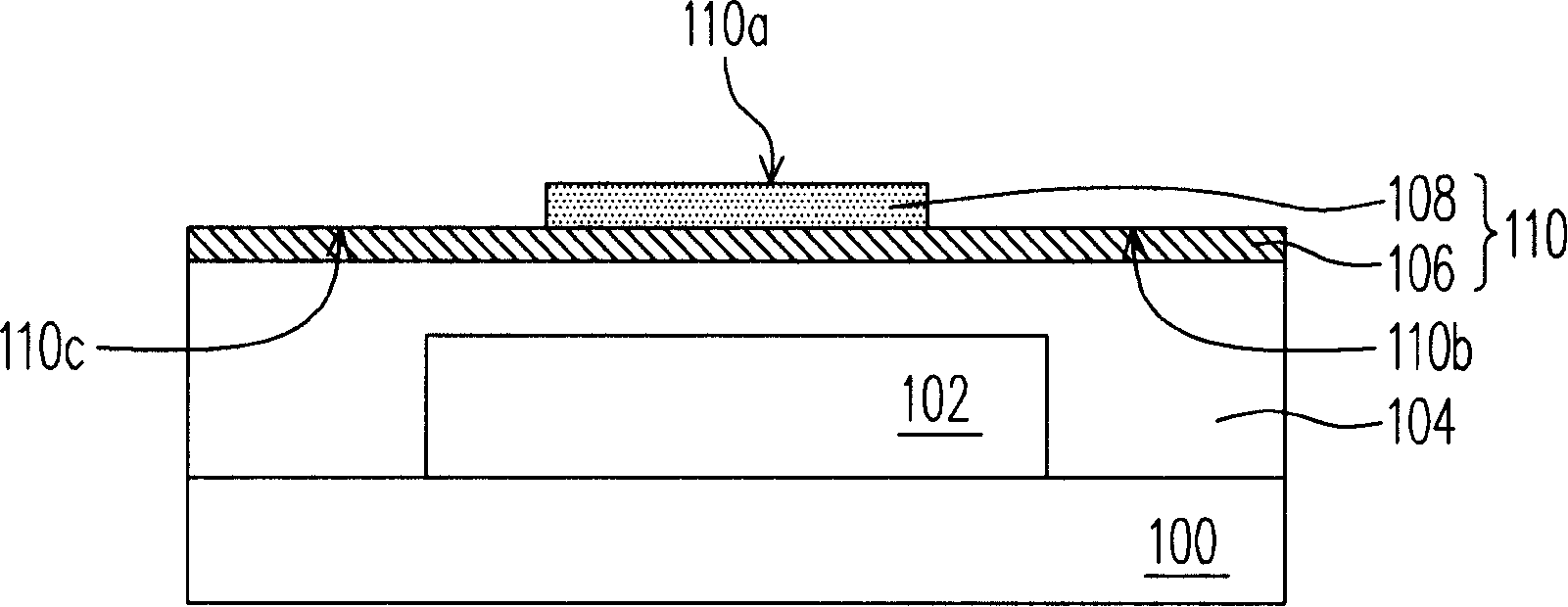

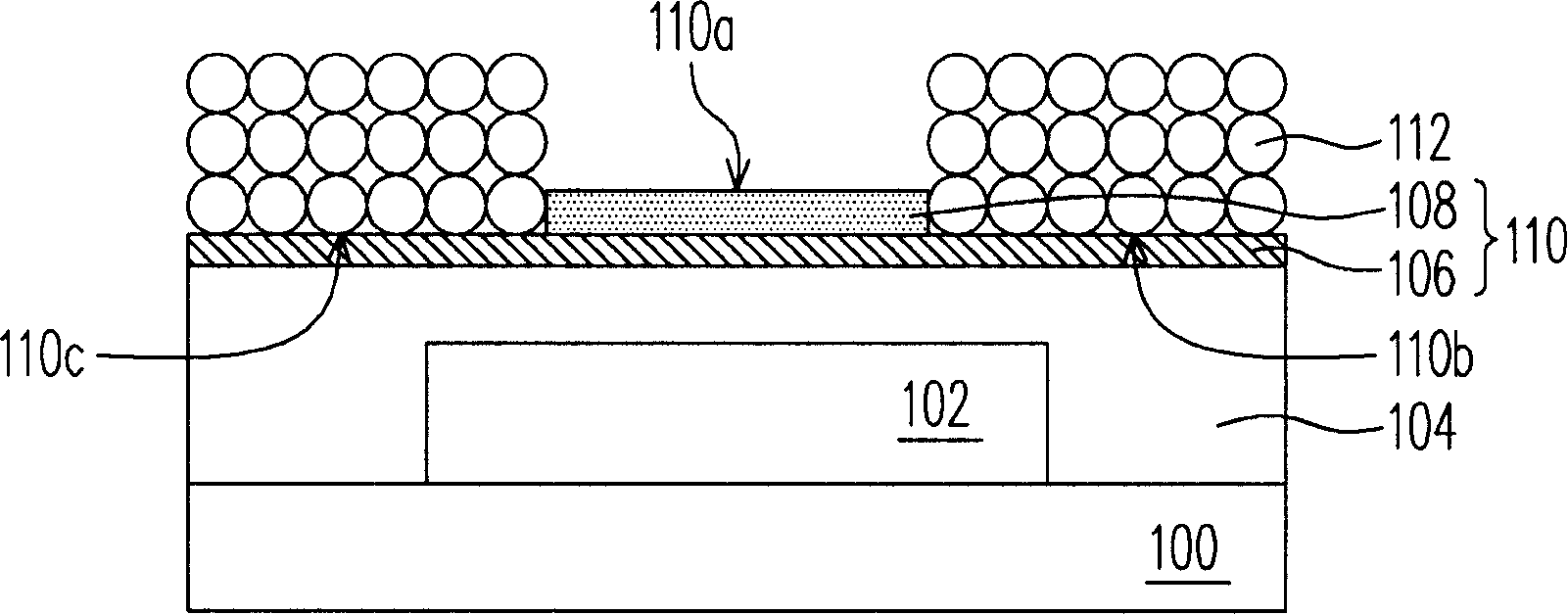

[0030] Figure 1A to Figure 1D It is a schematic cross-sectional flow diagram of a method for manufacturing an organic thin film transistor according to an embodiment of the present invention.

[0031] Please refer to Figure 1A , providing a substrate 100 . The substrate 100 is, for example, a glass substrate or a plastic substrate. Then, a gate 102 is formed on the substrate 100 . The material of the gate 102 is, for example, chromium (Cr), aluminum (Al), aluminum neodymium (AlNd), or other suitable metals or metal alloys. The forming method of the gate 102 is, for example, chemical vapor deposition (CVD) or physical vapor deposition (PVD). Of course, the material of the gate 102 can also be, for example, gold nanoparticles, silver nanoparticles, palladium nanoparticles, copper nanoparticles or other suitable metal nanoparticles, and its formation method is, for example, using a transfer printing method (printing) or an inkjet method. (ink-jet).

[0032] Then, please co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com