Method for processing ring shaped circular arc groove on circular column and special-purpose equipment

A special equipment, cylindrical surface technology, applied in metal processing equipment, milling machine equipment, details of milling machine equipment, etc., can solve the problems of difficult processing, low processing efficiency, cumbersome processing technology, etc., to achieve strong work reliability, cost saving, operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

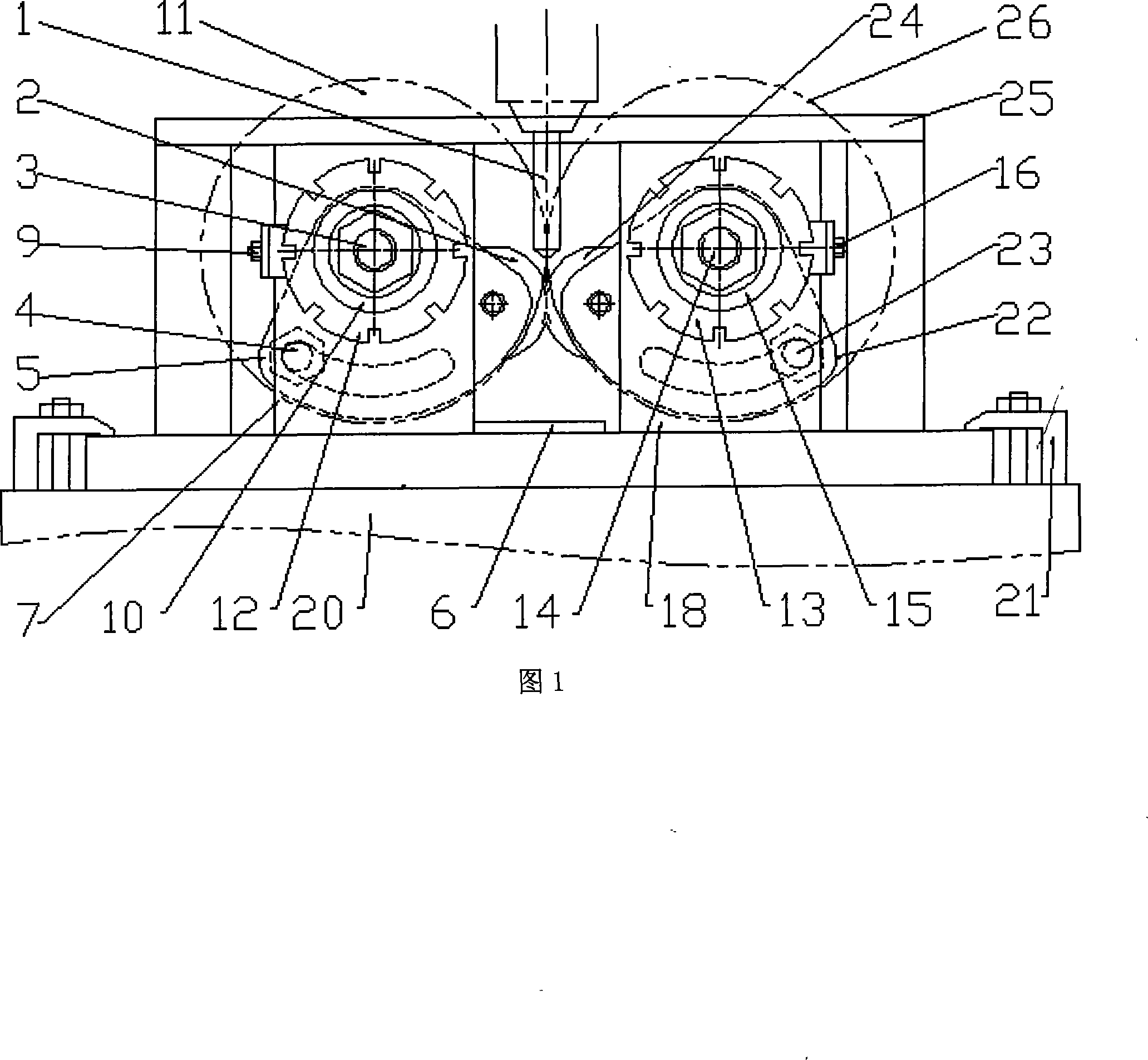

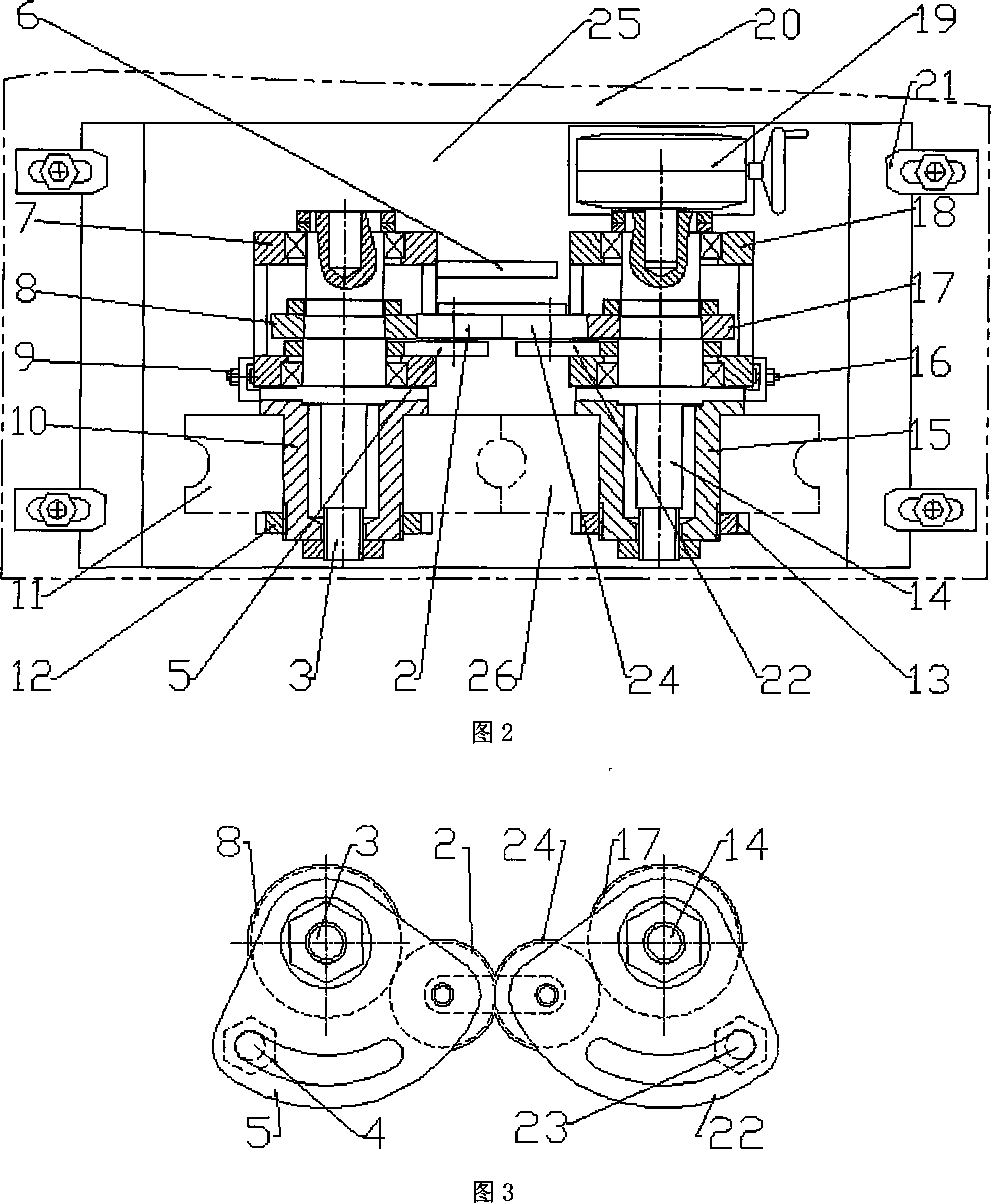

[0021] See Figure 1, Figure 2, Figure 3,

[0022] The method for processing the circular arc grooves on the cylindrical surface of the present invention adopts a paired processing method, that is, two workpieces are processed in pairs. The specific processing process is carried out in the following steps:

[0023] (1), the cylindrical workpiece 11,26 is clamped on the axle sleeves 10,15 of the workpiece rotating bracket 7,18, and the compression nuts 12,13 and locking screws 9,16 are tightened to make the cylindrical workpiece 11,26 and the workpiece The rotating brackets 7 and 18 are relatively fixed, and the workpiece rotating bracket 7 is moved horizontally along the key 6 on the support 25, that is, the left and right direction in Fig. The nut of screw rod 4,23 on the support 7,18 is with fixed circular arc connecting plate 5,22, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com